Micro-welding is a high-precision welding method employed to fuse minuscule (typically less than 1mm geometries) metal parts or features together. Traditionally, this requires a highly skilled specialist, utilizing a variety of skill sets and knowledge of various materials’ properties, taking into account all of the particular considerations involved in such a precise, delicate process. The Ford company first developed micro-welding to solve the problem of welding materials in a vacuum tube with a high melting point. The medical industry then utilized this advanced process for intricate, non-ferrous materials like tungsten, molybdenum, and nickel in orthodontic instruments and implantable medical devices. Naturally, micro-welding also offered great utility to the electronics industry as the components and connections are continuously see a reduction in size as the technology advances.

Micro-welding is a high-precision welding method employed to fuse minuscule (typically less than 1mm geometries) metal parts or features together. Traditionally, this requires a highly skilled specialist, utilizing a variety of skill sets and knowledge of various materials’ properties, taking into account all of the particular considerations involved in such a precise, delicate process. The Ford company first developed micro-welding to solve the problem of welding materials in a vacuum tube with a high melting point. The medical industry then utilized this advanced process for intricate, non-ferrous materials like tungsten, molybdenum, and nickel in orthodontic instruments and implantable medical devices. Naturally, micro-welding also offered great utility to the electronics industry as the components and connections are continuously see a reduction in size as the technology advances.

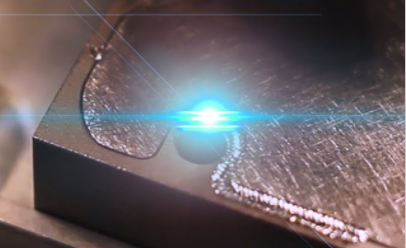

Laser micro-welding takes another step in the evolution of micro-welding technology. Standard laser welding offers many benefits over traditional welding, including providing high-quality welds at complex interfaces with varying thicknesses and geometries. Laser welding, a contact-free process, affords you increased flexibility in the design of your part and the layout of your workstation. Space constraints become less burdensome and more complex geometries and unique welding challenges become more feasible when you don’t need room for bulky and perhaps custom welding heads. OEM type lasers can be easily integrated into laser welding systems with a host of beam delivery options, including mounting to robotic arms for complete process automation. These same benefits apply in 445nm (blue) laser micro-welding, as well as providing void-free, sputter-free welds, advancing the capabilities of this technology even further. For some additional reading on standard laser welding, check out one of our recent articles titled “Blue Diode Lasers Enable High-Quality, Non-Ferrous Metal Welding.”

Laser micro-welding takes another step in the evolution of micro-welding technology. Standard laser welding offers many benefits over traditional welding, including providing high-quality welds at complex interfaces with varying thicknesses and geometries. Laser welding, a contact-free process, affords you increased flexibility in the design of your part and the layout of your workstation. Space constraints become less burdensome and more complex geometries and unique welding challenges become more feasible when you don’t need room for bulky and perhaps custom welding heads. OEM type lasers can be easily integrated into laser welding systems with a host of beam delivery options, including mounting to robotic arms for complete process automation. These same benefits apply in 445nm (blue) laser micro-welding, as well as providing void-free, sputter-free welds, advancing the capabilities of this technology even further. For some additional reading on standard laser welding, check out one of our recent articles titled “Blue Diode Lasers Enable High-Quality, Non-Ferrous Metal Welding.”

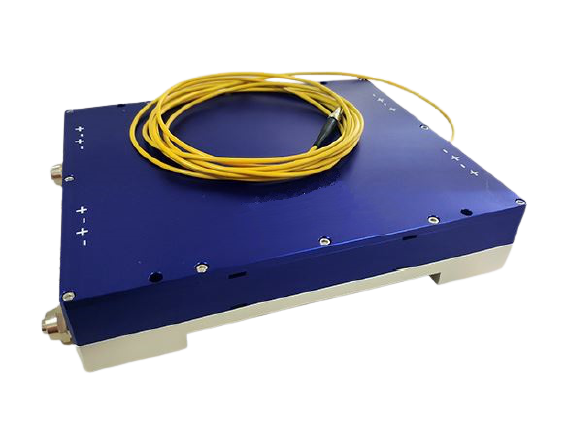

RPMC offers a few Blue Diode Laser options, perfect for intricate micro-welding of copper and other similar applications. The RPK445M is a high-power, multi-mode, OEM laser diode. These fiber-coupled, 445nm diode lasers are available in a few popular configurations, including 20W and 50W versions. These offer enough continuous wave (CW) output power to perform intricate micro-welding, delivered exactly where you want it at the work piece from a 200-micron core diameter pigtailed fiber optic cable, terminated with a SMA905 connector. Other power level options are available, currently up to 200W CW output power @ 445nm. Simply contact us to discuss your specific application requirements and what options we can provide to meet your needs.

These diodes utilize proprietary fiber-coupling techniques, resulting in volume products with high efficiency, stability, and superior beam quality. The RPK445M group achieves this high-quality beam by transforming the asymmetric radiation from the laser diode chip into an output fiber with a small core diameter by using special micro-optics, resulting in exceptional brightness. Additionally, these diode lasers go through extensive inspection and burn-in procedures at each step of the production process, guarantying reliability, stability, and lifetime.

RPK445M Key Features:

|

|

Talk to a knowledgeable Product Manager today by Contacting Us here, or by calling us at 636.272.7227!

SHIPS TODAY

SHIPS TODAY