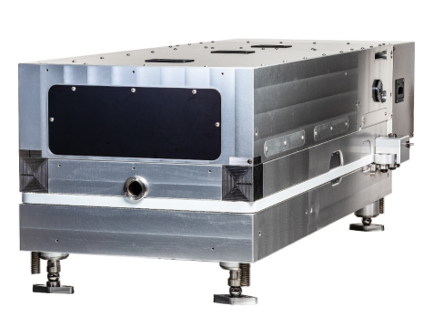

VaryDisk P500i

Thin Disk DPSS Laser, ps Pulsed, 1030 nm, up to 500 W / 4 mJ, 125 kHz, 10 ps

Key Features:

- Robust & simple

- Wavelength: 1030, 515, and 343 nm

- Output power: up to 500 W

- Optional SHG (250 W) and THG (100 W)

- Power & energy stability

- Customizable GUI

- Pulse energy: up to 4 mJ @ 10 ps

- Pulse duration depends on seed laser: (10 ps typ.)

- Beam quality: M^2 < 1.3

- Warm-up time: < 20 min

- Optional variable rep. rate

There are many configurations and options available. If you do not see exactly what you need below, please contact us!

Need Quantities? Have a question?

The VaryDisk Series is a versatile family of thin-disk laser systems that provide high pulse energies at high average powers and are suitable for lab or industrial use. These thin-disk regenerative amplifiers offer a range of output specifications and customization options, depending on the configuration and your specific application needs. The base configurations provide options for pulse widths in the fs, ps, and ns range, up to 1000 W average power, 150 mJ pulse energy, 1 kHz to 125 kHz rep. rate, and 1030 nm, 515 nm (SHG), and 343 nm (THG) wavelength options.

Benefits:

- High energy, multi-milli-Joule laser platform:

- Capable of delivering high-energy output, which means they can be used for a wide range of applications, including materials processing, scientific research, and more.

- Amplification of fs, ps, or ns pulses:

- Utilize a thin disk regenerative amplifier, which provides high amplification factors for fs, ps, or ns pulses, making them ideal for a wide range of applications where high peak power and high repetition rates are required.

- Adjustable output specifications:

- Adjustable output specifications to meet the specific needs of each customer, ensuring that they get the performance and capabilities they need.

- Customizable visual control interface:

- Visual control interface makes it easy for users to monitor and adjust laser performance. Additionally, they are programmable, which means users can customize laser performance and operating modes

- Various operating modes and different pulse characteristics:

- Range of operating modes and pulse characteristics available, which makes them highly versatile and suitable for a wide range of applications. This allows users to achieve the exact performance they need for their specific use case.

The VaryDisk series lasers offer versatile and customizable solutions for industrial, scientific, and research applications. They feature high-energy output and precise pulse amplification with adjustable output specifications and programmable operating modes. The VaryDisk ENERGY, in particular, is a fully functional laser system with chirped pulse amplification suitable for laboratory investigations and/or industrial use. Customers can tailor the output specifications of these thin disk laser systems to their specific needs. Overall, the VaryDisk series lasers provide easy visual control and a range of operating modes and pulse characteristics, making them an ideal choice for a wide range of applications.

If you have any questions or need more information, please contact us.

Options

We offer different options along with the VaryDisk PICO in order to increase the output power and/or to allow additional operating modes along with the generation of different pulse characteristics, e.g. At 1030 nm, pulse durations 10 ps and 10’s ns are bidirectionally switchable with a transition period of *** μs. Some of the available options are listed below. Please consult our team for possible combination choices and further information.

- Multiple seed laser options

- SHG (515 nm) & THG (343 nm)

- Variable repetition rates

Applications

- Industrial applications, e.g.

- Cutting, welding, scribing of transparent materials

- High speed and precision large surface machining

- Cutting and drilling of ceramics

- OLED processing

- ITO drilling / scribing

- Direct interference patterning

- Scientific research

SHIPS TODAY

SHIPS TODAY