Welcome to Lasers 101! Selecting a laser source for your application can be overwhelming. There are many types of lasers with various features, specifications, and integration levels to choose from. It is essential to understand the differences, benefits, and drawbacks of these options when choosing a laser for your project.

On this page, we start with the basics, explaining what a laser is and how it works. Then we discuss solid-state lasers, how we categorize them, and details on the various sub-types we offer. Finally, we have a section dedicated to helping you choose the best laser, where we discuss wavelengths, beam & optical parameters, integration levels, and more.

Over the last 25 years, we have worked extensively with many various laser companies, scientists and engineers, and other industry professionals in need of a laser source. This experience has provided us with a wealth of knowledge about how to match the right laser to the application. We hope to provide you with a solid overview of our laser types and information about their parameters to help answer any questions you may have so you can be more informed and comfortable while narrowing down the selection when choosing the best laser for your application.

For more details on any particular topic, click the links in the text to go to the dedicated page for that laser type or attribute, such as wavelength or pulse width. Alternatively, check out our Blogs, Whitepapers, and FAQs, here in our Knowledge Center.

Have questions?

Table of Contents:

What is a Laser?

What is a Solid State Laser?

Types of Solid State Lasers

Overview of Laser Diodes

Overview of CW Lasers

Overview of Pulsed Lasers

Selecting the best Laser

Wavelength

Beam and Optical Parameters

Integration Levels

What is a Laser?

Well, let’s start from the start. LASER is an acronym for Light Amplification by Stimulated Emission of Radiation. The acronym succinctly describes how a laser works. You can amplify electromagnetic radiation or light by using an energy source to stimulate the emission of photons from the atoms in a material. Lasers have completely changed the world with more and more advancements as time goes by. Things once thought impossible or never even dreamed of, have now become possible, even commonplace, thanks to the unique benefits lasers offer.

|

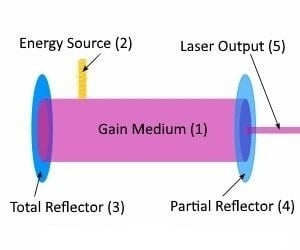

| Laser Resonator / Cavity Diagram |

Ok. So, what IS a laser exactly?

A laser is a device with specific components and features which allow it to generate an intense, collimated, coherent beam of photons or light through the process of optical amplification. There are many types of lasers, including gas lasers, solid-state lasers, dye lasers, semiconductor diode lasers, and excimer lasers. There are also different levels of integration within each laser type, ranging from components to OEM modules to complete turn-key systems. All these laser types share a basic set of component parts:

- A gain medium capable of sustaining stimulated emission

- An energy source to pump or excite the atoms in the gain medium

- A total reflector to reflect photons through the gain medium for multiple passes

- A partial reflector / output coupler to reflect photons but allow a percentage to leave the resonator

- Laser beam output through the partial reflector as the total amount of amplified light increases

Very simply put, lasers function as follows: The gain medium is comprised of a special material, typically crystal, glass, liquid, dye, or gas which contain atoms with properties conducive to the lasing process. This means the atoms within the material can be excited to a semistable state when excited or energized by the pump source. A pump source typically takes the form of a flash lamp, electrodes, or even a laser (e.g., a diode laser for diode-pumped solid-state or DPSS lasers). When the excited atoms within the gain medium drop back down to their ground state, photons are released. As this plays out, other nearby atoms absorb these photons, and this process repeats many, many times, increasing energy.

Very simply put, lasers function as follows: The gain medium is comprised of a special material, typically crystal, glass, liquid, dye, or gas which contain atoms with properties conducive to the lasing process. This means the atoms within the material can be excited to a semistable state when excited or energized by the pump source. A pump source typically takes the form of a flash lamp, electrodes, or even a laser (e.g., a diode laser for diode-pumped solid-state or DPSS lasers). When the excited atoms within the gain medium drop back down to their ground state, photons are released. As this plays out, other nearby atoms absorb these photons, and this process repeats many, many times, increasing energy.

This repeated process is called population inversion – increasing the population of electrons at a higher energy state to the point that laser action can occur. This process is further amplified as the light oscillates between the mirrors (total reflector and partial reflector). On each subsequent oscillation between mirrors, the atom excitation mechanism is multiplied. The partial reflector or output coupler will transmit a small percentage of the total amplified light in the form of a monochromatic, coherent, and directional beam of light – a laser beam. This explanation is meant to illustrate the process in a simplified manner and by no means covers all nuanced aspects of how various forms of laser technology generate laser beams.

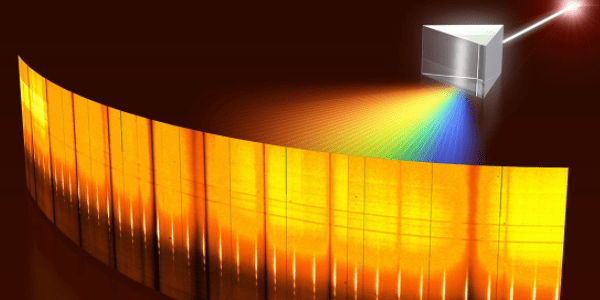

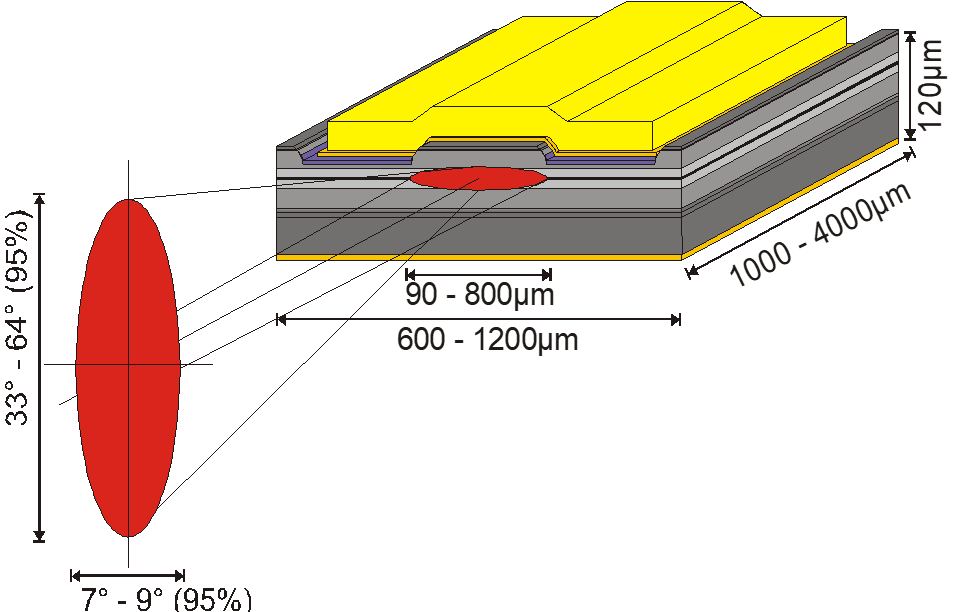

Most common lasers emit light from the deep UV (ultraviolet) to the far IR or long-wave infrared (LWIR) portion of the electromagnetic spectrum. Ultraviolet has a shorter wavelength and a higher frequency, while infrared is a longer wavelength and therefore a lower frequency. So, laser wavelength and frequency are inversely proportional to each other, shown by the laser frequency formula C = f ⋅ λ, where C is the speed of light, f is frequency, and λ (lambda) is the wavelength. Since the speed of light is constant, when wavelength decreases, frequency necessarily increases. The following electromagnetic spectrum diagram illustrates the known range of electromagnetic radiation, the relationship between wavelength and frequency, and the small slice of the total spectrum that humans perceive as visible light. Jump down to ‘Wavelength‘ for more details on specific wavelengths and their relationship to laser types.

What is a Solid-State Laser?

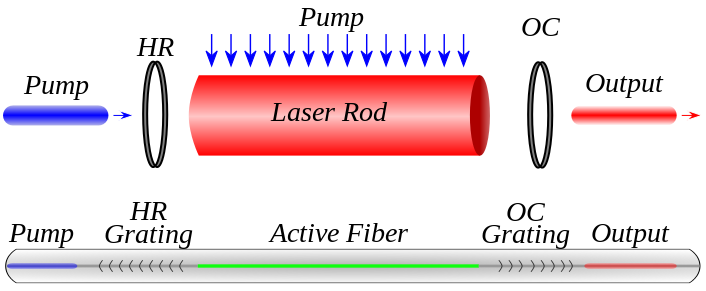

A solid-state laser consists of a gain medium that is a solid, rather than a liquid as used in dye lasers or the gas that’s in a gas laser. The gain medium of a solid-state laser consists of a glass or crystalline host material (e.g., a few mm in diameter cylindrical rod in an Nd:YAG or disk shape in a thin disk laser). This host material must be doped with either transition metal ions (e.g., titanium – Ti3+ for Ti:Sapphire lasers) or rare earth ions (e.g., neodymium – Nd3+, ytterbium – Yb3+, or erbium Er3+). There are many host materials in which laser excitation has been achieved, but relatively few types are in widespread use. Of these, the most common ones are neodymium-doped yttrium aluminum garnet (Nd: YAG crystal), neodymium-doped yttrium lithium fluoride (Nd:YLF), neodymium-doped glass (Nd:glass), and either erbium-doped or ytterbium-doped glasses (Er:glass / Yb:glass).

A solid-state laser consists of a gain medium that is a solid, rather than a liquid as used in dye lasers or the gas that’s in a gas laser. The gain medium of a solid-state laser consists of a glass or crystalline host material (e.g., a few mm in diameter cylindrical rod in an Nd:YAG or disk shape in a thin disk laser). This host material must be doped with either transition metal ions (e.g., titanium – Ti3+ for Ti:Sapphire lasers) or rare earth ions (e.g., neodymium – Nd3+, ytterbium – Yb3+, or erbium Er3+). There are many host materials in which laser excitation has been achieved, but relatively few types are in widespread use. Of these, the most common ones are neodymium-doped yttrium aluminum garnet (Nd: YAG crystal), neodymium-doped yttrium lithium fluoride (Nd:YLF), neodymium-doped glass (Nd:glass), and either erbium-doped or ytterbium-doped glasses (Er:glass / Yb:glass).

|

|

Solid-State Laser Diagram Examples |

The gain medium is typically optically pumped using either a flashlamp, or laser diodes by side-pumping or end-pumping. Typically, flashlamp-pumped lasers are lower cost and can provide high power output. Though, these pump sources usually exhibit low power efficiency levels, relatively shorter lifetimes (must replace the flashlamp more often than when optical pumping with diodes), and they are prone to causing thermal lensing effects in the gain medium. Diode-pumped solid-state (DPSS) lasers tend to be more efficient and compact, with lower overall maintenance, longer lifetimes, and provide better beam quality. Recently solid state DPSS lasers have become more common as the cost of high-power laser diodes has gone down, allowing more people to benefit from solid state laser advantages.

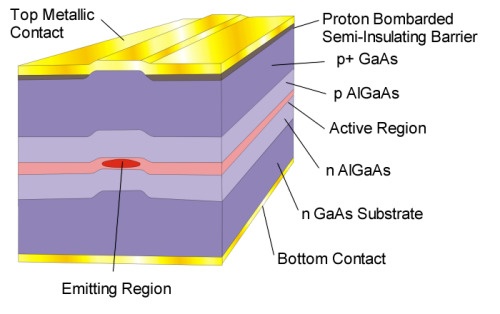

Semiconductor Lasers are also classified as solid-state lasers, but are considered a separate class or type of solid-state lasers and are often called Laser Diodes or Diode Lasers. Laser Diodes use electrical power as an energy source and doped p-n junctions as a gain medium. The front facet is a partial reflector, and the back facet is the total reflector. Therefore, the front facet is the output facet of the laser emission. Below, we’ll talk more about laser diodes, as well as the other types of solid-state lasers we offer.

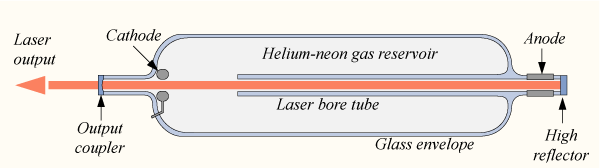

Gas Lasers: Gas Lasers are NOT solid-state lasers. While most of our products are solid-state lasers, we are starting to expand our product portfolio, allowing us to offer some new, different laser types. Currently we offer helium-neon (HeNe or He-Ne) Gas Lasers, which we have categorized under CW Lasers and LD Modules for convenience. We may start breaking these other laser types out into their own proper categories and types as we grow our ever-expanding list of available laser products.

Types of Solid-State Lasers

This Guide will focus on the many types of high-quality Solid-State Lasers provided by RPMC. Our three main categories of laser products include Laser Diodes, Pulsed Lasers, and Continuous Wave (CW) Lasers & Laser Diode (LD) Modules in addition to Laser Amplifiers. Within each category, we have grouped all our products into various laser types. Each laser category, and sometimes the laser type within the categories, will have distinct advantages and disadvantages based on the specifications needed for your application. See our Blogs, Whitepapers, and FAQs for further reading covering various topics, including benefits of particular laser types, information and tips like improving diode lifetime and how to get space-qualified, application specifics & their laser source requirements, and more!

Overview of Laser Diodes

|

|

Laser Diode Diagram |

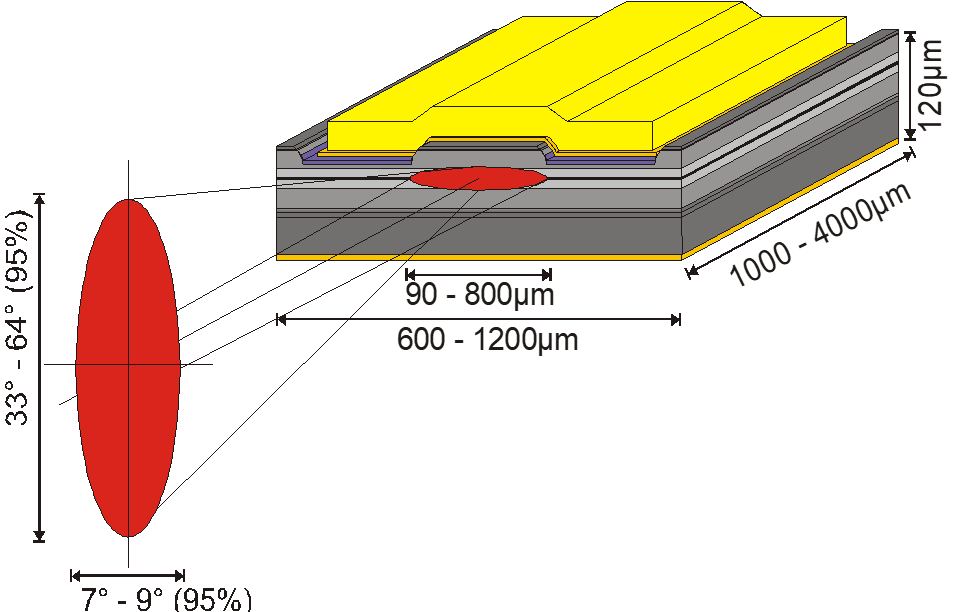

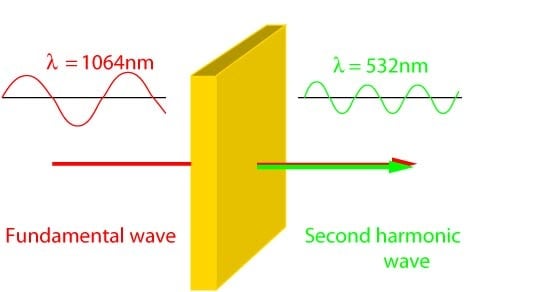

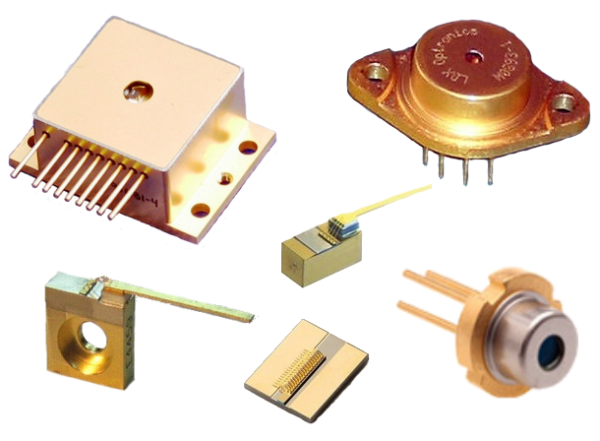

A Laser Diode or semiconductor laser is the simplest form of Solid-State Laser. Laser diodes are commonly referred to as edge emitting laser diodes because the laser light is emitted from the edge of the substrate. The light emitting region of the laser diode is commonly called the emitter. The emitter size and the number of emitters determine output power and beam quality of a laser diode.

Electrically speaking, a laser diode is a PIN diode. The intrinsic (I) region is the active region of the laser diode. The N and P regions provide the active region with the carriers (electrons and holes). Initially, research on laser diodes was carried out using P-N diodes. However, all modern laser diodes utilize the double-hetero-structure implementation. This design confines the carriers and photons, allowing a maximization of recombination and light generation.

Laser Diode Epitaxy: the epitaxial structure of a laser diode is typically grown utilizing one of the crystal growth techniques, starting with an N-doped substrate, then growing the I-doped layer (active region), proceeded by the P-doped layer, and finally, a contact layer. The active region of a laser diode typically consists of quantum wells. These wells allow for a lower threshold current and a higher operating efficiency in laser diodes.

- Single-mode laser diodes typically have an emitter that is approximately 3µm – 7µm x 1µm, dependent on the wavelength. The emitter allows only a single mode to propagate along the active region.

- Multimode laser diodes have the emitter width enlarged to allow multiple modes in the active region. The emitters can be 30µm – 300 µm x ≈ 1 µm.

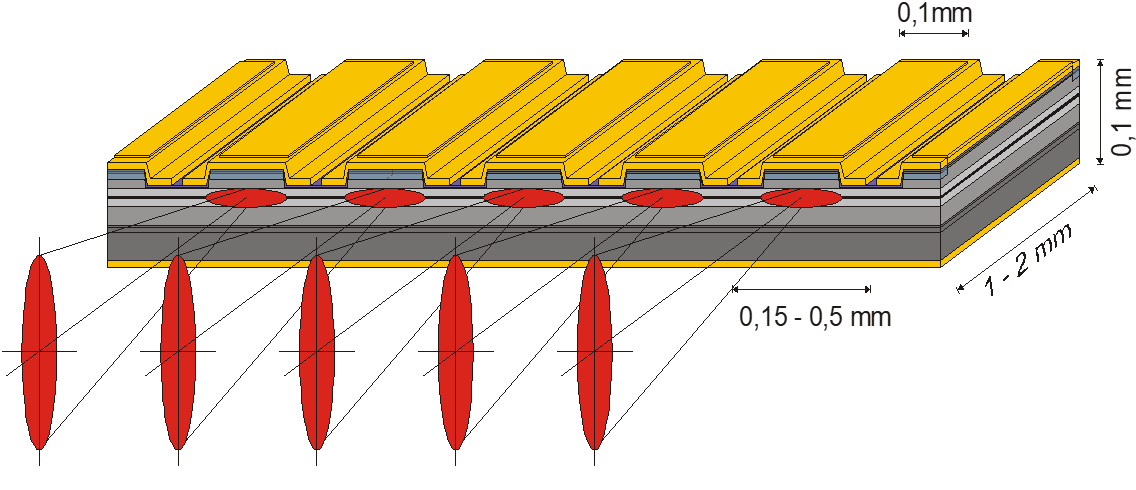

These Fabry-Perot Diode Lasers with a single emission region (Single Emitter) are typically called laser diode chips, while a linear array of emitters is called a Laser Diode Array (Bars). Laser diode bars typically use multimode emitters. The number of emitters per substrate can vary from 5 emitters to 100 emitters.

Some examples of our MANY Laser Diode Package options:

|

|

|

|

|

| 9mm Package | Butterfly Package | Fiber Coupled Package | Microchannel Cooled | Turn-Key System |

Types of Laser Diodes:

Single Emitters have a single emitting region (Emitter) that emits light. Single Emitters can be multimode or single-mode depending on the emitter size.

|

| Laser Diode Emitter Size & Emission Diagram |

- Single-Mode Laser Diodes are single transverse mode, they may or may not be single longitudinal mode. They are used for applications where high output power is not required, but a good, diffraction-limited beam is essential. An output power of up to ≈ 1 W depending on the wavelength. Available in free-space and fiber-coupled packages.

- Stabilized Single-Mode Laser Diodes use an external feature to ensure single longitudinal mode. Stabilized laser diodes include DFB, DBR, and external cavity laser diodes. Output powers typically range from 1mW – 600mW depending on the wavelength. Available in free-space and fiber-coupled packages.

- Multimode Laser Diodes also known as Broad Area Diode Lasers, offer higher output power than single mode laser diodes. For applications where higher powers are required, and beam quality is not as critical. Multimode laser diodes are spatially and longitudinally multimode. Output powers are in the order of 100mW – 10W per emitter depending on the wavelength. Available in free-space and fiber-coupled packages.

- Stabilized Multimode Laser Diodes use an external feature to ensure single longitudinal mode. Stabilized multimode laser diodes are typically external cavity laser diodes. Output powers typically range from 50mW – 8W depending on the wavelength. Available in free-space and fiber-coupled packages.

Multi-emitters include devices that utilized multiple single emitters in the package, usually multimode laser diodes and typically fiber-coupled output. By combining the output of multiple single emitter devices, the output power can be increased. An advantage of Multi-Emitters is they require lower current than a laser diode bar-based approach.

|

| Laser Diode Bar Diagram |

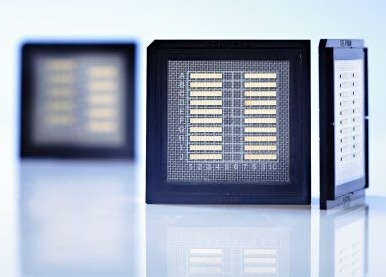

Laser Diode Arrays (Bars) have multiple emitters in a single substrate. Laser Diodes Bars can have as many as 100 emitters and are typically 1 cm long. This linear array of emitters lay side by side and, together with the non-emitting areas between the emitters, they form the so-called bar. The number, the width, and the spacing of the emitters are dependent on the manufacturer and the optical performance required from the bar. The relative value of the emitting areas in the active layer with respect to the bar width is called filling factor (FF). Typical filling factors are 30% – 90%. The center-to-center distance between two adjacent emitters is called emitter pitch. Output powers are available in the order of 10W – >300W per bar. Laser diodes bars are available as unmounted laser diode bars or mounted in conductively or actively cooled packages.

Stacks use laser diode bars built up, either vertically or horizontally, in a single package. Microchannel cooling is often used in Laser Diode Bar Stacks due to a large amount of waste heat in a small area. Laser Diode Bars and Stacks are available in several free-space and fiber-coupled packages.

|

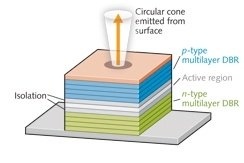

| VCSEL Emission |

VCSELs (Vertical Cavity Surface Emitting Lasers) emit light perpendicular to the mounting surface as opposed to parallel to the mounting surface like conventional edge emitting laser diodes. VCSELs offer a uniform spatial illumination in a circular illumination pattern with low speckle. VCSELs can act as a combination of LEDs and edge-emitting lasers (EEL). They combine many of the advantages of LEDs (such as surface emission, wafer-level testing and diverse packaging options) with the advantages of EELs (such as coherence, beam quality and efficiency).

- Strengths – Low cost, Wide wavelength selections, Low Complexity, many Integration levels

- Weaknesses – Beam quality, Output energy

Distributed Feedback (DFB) Laser Diodes are single-frequency and offer a Narrow Linewidth with good side mode suppression ratio (SMSR). Furthermore, DFB Laser Diodes utilize a Bragg grating to ensure single-frequency emission. This grating is etched onto the end surface of the gain medium in the form of a periodic structure, allowing only one wavelength to emit from the diode, rather than one center wavelength with a couple of lower power side wavelengths that you typically get from a standard Fabry-Perot laser diode.

Volume Bragg Grating (VBG) Laser Diodes are similar to distributed feedback (DFB) lasers. However, instead of etching the grating on the surface, VGB Laser Diodes are etched within the volume of a transparent material. This method provides reflections in a narrow optical bandwidth, ultimately providing wavelength stabilization and narrow linewidths.

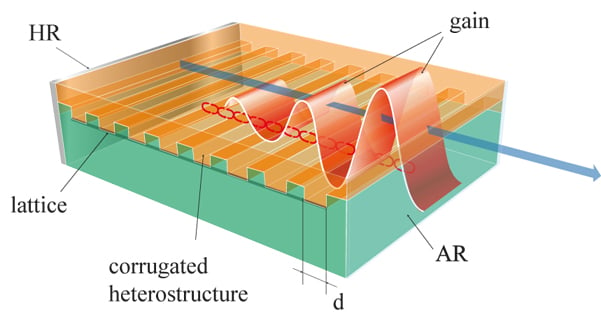

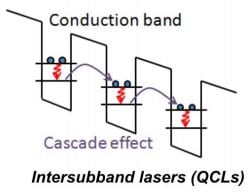

Quantum Cascade Lasers (QCLs) are intersubband semiconductor lasers that emit in the mid- to far-infrared or long-wave infrared (LWIR) portion of the electromagnetic spectrum from 4 to 17+ µm. We offer two types of quantum cascade lasers, depending on your needs. Fabry-Perot QCLs provide quasi continuous wave (QCW), multimode output. Distributed feedback (DFB) QCLs provide continuous wave (CW), single-mode output with narrow linewidths.

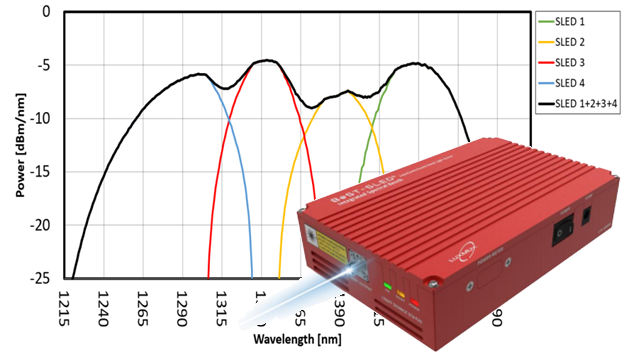

Superluminescent Laser Diodes (SLED or SLD, superluminescence diodes or Superluminescent light-emitting diodes = Superluminescent LEDs) are optoelectronic semiconductor devices that emit broadband optical radiation (broadband light) based on superluminescence. SLED devices provide an optical bandwidth typically around 40 to 70 nm FWHM and are used for telecom test equipment, optical coherence tomography, and many other applications.

Multi-Wavelength Laser Diodes provide multiple CW wavelengths from the same device. Multi-Wavelength Laser Diodes are typically utilized for medical applications, or applications requiring an RGB (red / green / blue) laser source.

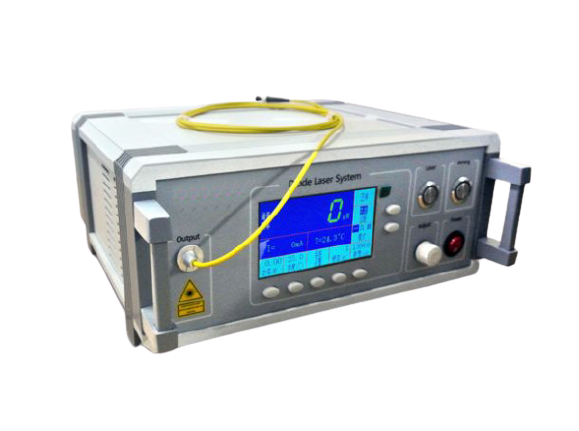

Turn-Key Systems include the laser diode, the optics, thermal management, user interface, and the electronics required as a complete system and requires minimal setup time. Turn-Key Systems allow for quick and convenient benchtop lab use with minimal setup and little to no need for extra components.

Tunable Lasers include a couple different categories / types of lasers. For the diode category, while not field tunable, we offer tunable quantum cascade lasers (QCLs), which allow for a customer-specified wavelength to be set by the manufacturer. For the pulsed laser category, we offer Tunable OPO, ultrafast OPA, and picosecond tunable supercontinuum laser configurations with tunable wavelengths that allow the user to configure the laser to their desired wavelength regime – see more, below in our Pulsed section.

Custom Lasers include off the shelf configurable laser systems, customization of existing products, and completely Custom Laser systems designed and manufactured to your exact specifications. Many of our products are configurable by request, if not outright designed with customization in mind. Start a conversation with us today about a custom laser solution, or browse our vast product portfolio and ask about any custom options you may be interested in. We will do what we can to provide you with exactly what you need! Our Custom Lasers Section involves all of our laser categories and types.

Have questions?

Overview of CW Lasers and LD Modules

CW Lasers and Laser Diode (LD) Modules emit continuous light, unlike Pulsed Lasers, which store energy and emit the stored, concentrated energy in periodic bursts or pulses. Some wavelengths are achieved using Laser Diodes, and other wavelengths are achieved using a CW Diode-Pumped Solid-State (DPSS) Laser. For example, CW Yellow Wavelengths are only available from our CW DPSS (or HeNe) products. Pulsed yellow wavelengths are available from our Q-TUNE pulsed tunable optical parametric oscillator, our Q-SHIFT shifted fundamental wavelength DPSS lasers as well as some other options. For some further reading on yellow wavelengths, see our blog on this topic: “How do DPSS Lasers Fill the ‘Yellow Gap’?“

RPMC defines CW Lasers & LD Modules as:

- CW Output

- Have thermal management included

- Have an electrical interface for power and control included

The beam parameters vary depending on the laser source of the module, but in general, the CW Modules have good beam quality and power stability.

- Strengths – Wide wavelength range, Good Beam quality, OEM or Plug and Play Versions available, Reasonable cost, Flexible platform

- Weaknesses – Output Energy

Some Examples of Our CW Lasers and LD Modules:

|

|

|

|

| OEM Laser Module | Plug and Play / Benchtop / Turnkey Laser Module | Multi-Wavelength Combiner | CW Fiber Laser |

Types of CW Lasers and LD Modules:

Laser Diode Modules use a laser diode as the laser source, but also include thermal management and an electrical interface for power and control. Typically, plug-and-play / benchtop / turnkey systems provide a graphical user interface (GUI). Laser Diode Modules are simple, user-friendly, and available in OEM or Plug-and-Play configurations.

CW DPSS Lasers involve laser diodes pumping a laser gain medium. CW DPSS Lasers take advantage of the relatively narrow spectral linewidth of diode lasers, in conjunction with their high brightness. Thus maximizing absorption and therefore increasing efficiency.

CW Gas Lasers & Modules produce a laser beam by discharging an electric current through a gas (e.g., CO2, Helium-Neon, or Argon-Ion). The gas laser was the first continuous-light laser and the first laser to operate by converting electrical energy to a laser light output. There are many types of CW Gas Lasers. We currently offer Helium-Neon (HeNe / He-Ne) laser modules and replacement tubes.

CW Fiber Lasers are a specific subset of DPSS lasers. However, instead of a single crystal, they utilize a doped fiber optic cable as the gain medium. Typically, they utilize rare-earth elements like erbium, ytterbium, and neodymium as the doping agent. CW Fiber Lasers can have several advantages over traditional DPSS lasers.

Line Modules are a specialized type of laser, designed primarily for various types of alignment and measurement applications. Machine vision Laser Line Modules typically shape the beam into lines, dots, and other geometric patterns (such as crosses, circles, and grids) and they can come in a wide variety of wavelengths and powers, depending on the systems requirements.

Multi-Wavelength Combiner Modules merge multiple laser sources into a single unit with individual and independent control for each laser in an easy to use interface. Multi-Wavelength Combiner Modules allow you to mix and match critical wavelengths to meet your application requirements, whether you’re doing Fluorescence Recovery After Bleaching (FRAP), Light Sheet Microscopy, Flow Cytometry, or some other application in the Life Science, Medical, or other markets.

Multi-Wavelength Combiner Modules merge multiple laser sources into a single unit with individual and independent control for each laser in an easy to use interface. Multi-Wavelength Combiner Modules allow you to mix and match critical wavelengths to meet your application requirements, whether you’re doing Fluorescence Recovery After Bleaching (FRAP), Light Sheet Microscopy, Flow Cytometry, or some other application in the Life Science, Medical, or other markets.

Custom Lasers include off the shelf configurable laser systems, customization of existing products, and completely custom laser systems designed to your exact specifications. Many of our products are configurable by request, if not outright designed with customization in mind. Start a conversation with us today about a custom solution, or browse our vast product portfolio and ask about any custom options you may be interested in. We will do what we can to provide you with exactly what you need! Our Custom Lasers Section involves all of our laser categories and types.

Have questions?

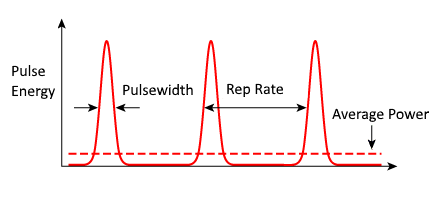

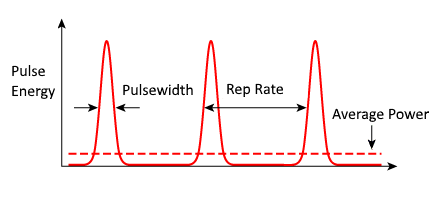

|

| Laser Pulses Diagram |

Overview of Pulsed Lasers

Pulsed Lasers have a gain medium that is typically optically pumped using either a flashlamp (arc lamp) or by laser diodes (DPSS). Utilizing pulse generation techniques like mode-locking and active and passive Q-switching, these lasers produce high peak power or high energy pulses with a lower duty cycle by storing energy and releasing it in pulses. This method of repeated energy storage and release is unlike CW Lasers and Laser Diodes which emit energy continuously. Pulsed Lasers are available in wide range of pulse widths from femtoseconds through milliseconds, with repetition rates ranging from single shot to Mhz.

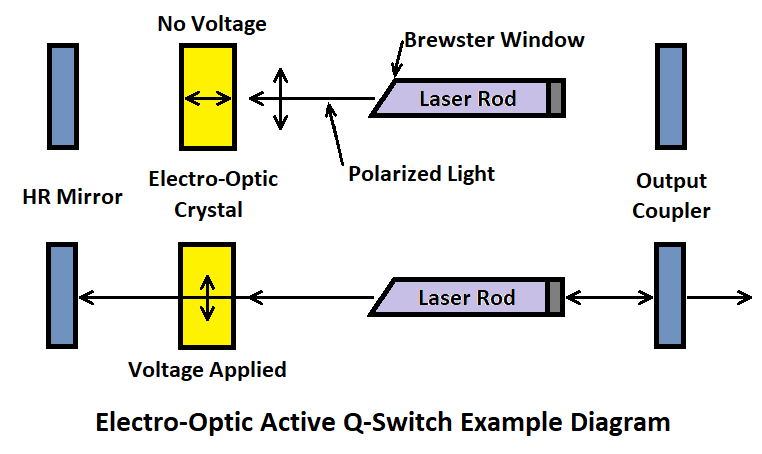

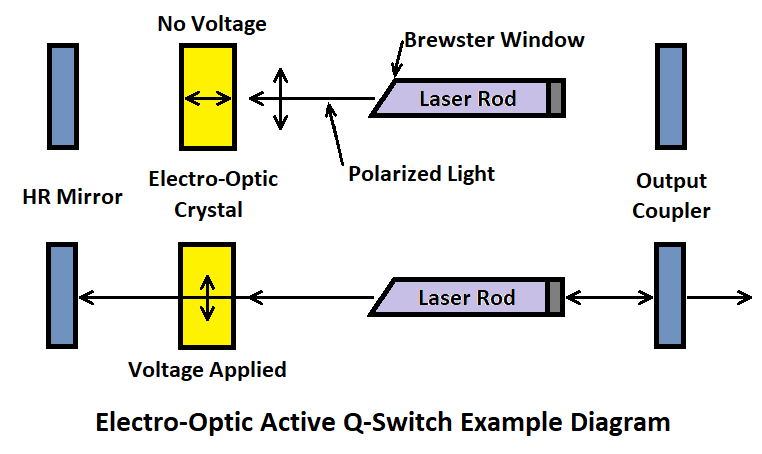

Active Q-Switched Lasers allow the precise control of both the pulse width and repetition rate of the laser using an on / off system of blocking or emitting photons. Active Q-switches are typically electro-optic, acousto-optic, or magneto-optic modulators, although other methods may be used, such as a mechanical shutter, optical chopper wheel, or spinning mirror/prism.

Active Q-Switched Lasers allow the precise control of both the pulse width and repetition rate of the laser using an on / off system of blocking or emitting photons. Active Q-switches are typically electro-optic, acousto-optic, or magneto-optic modulators, although other methods may be used, such as a mechanical shutter, optical chopper wheel, or spinning mirror/prism.

- Strengths – Control over pulses, typically higher pulse energies

- Weaknesses – Higher cost, System complexity, much larger than passive

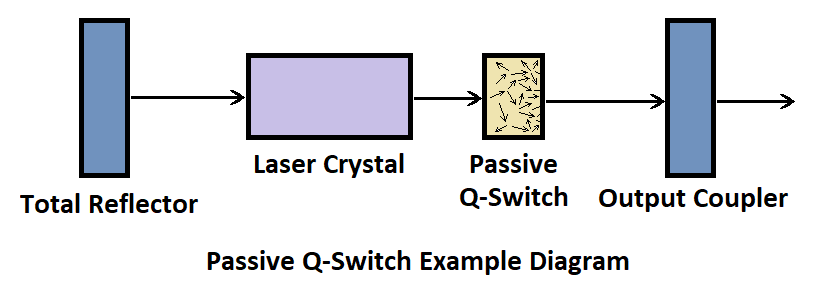

Passive Q-Switched Lasers contain a Saturable Absorber that, when continuously pumped, produces a regular pulse train. Due to the passive nature of this technology, passive Q-Switched lasers exhibit higher jitters than actively q-switched lasers. Passive Q-Switches can be based on a special dye, a passive semiconductor, or a crystal material (typically Cr:YAG).

Passive Q-Switched Lasers contain a Saturable Absorber that, when continuously pumped, produces a regular pulse train. Due to the passive nature of this technology, passive Q-Switched lasers exhibit higher jitters than actively q-switched lasers. Passive Q-Switches can be based on a special dye, a passive semiconductor, or a crystal material (typically Cr:YAG).

- Strengths – Lower cost, System simplicity, Compact size

- Weaknesses – Increased timing jitter, typically lower pulse energies

- Mode-Locked Lasers (Ultrafast Lasers) produce ultrashort, typically sub-picosecond pulses, at high repetition rates (up to 80 MHz for our current product offerings) by mode-locking a large number of phase-locked longitudinal modes from a broadband laser or from a material with a large gain bandwidth.

Some Examples of Our Pulsed Lasers:

|

|

|

| Microchip Laser | Nanosecond Laser | Fiber Laser |

Types of Pulsed Lasers

Pulsed DPSS Lasers use laser diodes as the pump light (pump source) for a laser gain medium. Pulsed DPSS Lasers take advantage of the relatively narrow spectral linewidth of diode lasers in conjunction with their high brightness in order to maximize absorption and therefore increase efficiency. Pulsed DPSS lasers are also far more compact and require less maintenance than flash lamp-pumped lasers. DPSS Lasers can also benefit from second, third, fourth, and even fifth harmonic generation, allowing wavelengths from the UV to the IR spectral regions.

Pulsed Fiber Lasers are a specific subset of DPSS lasers. Instead of a crystal, these lasers utilize a doped fiber optic cable as the gain medium. Typically, they utilize rare-earth elements like erbium, ytterbium, and neodymium as the doping agent. Pulsed Fiber Lasers can have several advantages over traditional DPSS lasers.

Ultrafast Lasers produce ultrashort pulses < 10 ps (typically in the femtosecond range), at high repetition rates (up to 80 MHz for our current product offerings) by mode locking a large number of phase-locked longitudinal modes from a broadband laser or from a material with a large gain bandwidth. Ultrafast Lasers are unique in their ability to produce these ultrafast, ultrashort pulses which are ideal for applications including Non-Thermal Ablation and Two-Photon or Multi-Photon Microscopy.

Microchip Lasers or Micro Lasers are a specific subset of q-switched DPSS lasers. Microchip Lasers utilize a passive q-switch, monolithically bonded to the laser crystal. These passive q-switches, which are typically semiconductor saturable absorber mirrors (SESAM), act as both the q-switch and the output coupler allowing for extremely small optical cavities, and therefore, a very compact overall footprint.

Tunable Lasers include a couple different categories / types of lasers. For the Pulsed category, we offer tunable optical parametric oscillator (OPO) lasers, producing wavelengths in the 210/410 – 2300 nm range and 1380 – 4500 nm range. These Pulsed DPSS Tunable Lasers can be ‘tuned’ to many selectable wavelengths within this range, according to your current needs.

MIL-Spec Lasers (or military lasers) are specifically designed for Low SWaP and demanding ruggedization requirements for military deployment. Typically, these lasers go through extensive shock and vibration testing to ensure durability in hostile environments. Most Military-Grade Lasers are either direct diode sources or DPSS lasers due to their long lifetimes and minimal maintenance requirements.

MIL-Spec Lasers (or military lasers) are specifically designed for Low SWaP and demanding ruggedization requirements for military deployment. Typically, these lasers go through extensive shock and vibration testing to ensure durability in hostile environments. Most Military-Grade Lasers are either direct diode sources or DPSS lasers due to their long lifetimes and minimal maintenance requirements.

Micromachining Systems are designed as an all-in-one package capable of handling a variety of industrial applications like micromachining applications. Available in a 266 nm UV version and a 532 nm Green version, our Micromachining Systems include everything for needed for direct laser micro-processing in a single monolithic element. Furthermore, live microscope imaging of the sample is available during all process phases for alignment and immediate quality check.

Micromachining Systems are designed as an all-in-one package capable of handling a variety of industrial applications like micromachining applications. Available in a 266 nm UV version and a 532 nm Green version, our Micromachining Systems include everything for needed for direct laser micro-processing in a single monolithic element. Furthermore, live microscope imaging of the sample is available during all process phases for alignment and immediate quality check.

Custom Lasers include off the shelf configurable laser systems, customization of existing products, and completely custom laser systems designed to your exact specifications. Many of our products are configurable by request, if not outright designed with customization in mind. Start a conversation with us today about a custom solution, or browse our vast product portfolio and ask about any custom options you may be interested in. We will do what we can to provide you with exactly what you need! Our Custom Lasers Section involves all of our laser categories and types.

Have questions?

Selecting the best Solid-State Laser for your application:

The first step in finding the right laser for your application is to define the laser type. Whether it’s a Laser Diode, a CW Laser / LD Module, or a Pulsed Laser, the type of laser you select will determine what main characteristics are important to your application. For example, if you select a CW laser module, the pulse width and repetition rate are not characteristics for CW Lasers.

Once the laser type is chosen, the next step is to define the main laser specifications needed in your laser. These typically include the wavelength, the beam, any optical parameters, the integration level, and the pulse width and repetition rate, if applicable. The importance of each of these characteristics will depend on your application. For some applications, the exact wavelength may not be important, but excellent beam quality or specific pulse width is critical. In other applications, the wavelength must be tightly controlled with a narrow spectrum, while you can be flexible with other specifications. Knowing the critical specifications for your application is a crucial part of selecting the right laser source.

Here is some information on the laser characteristics that will need to be defined:

|

Ultraviolet Laser Wavelength |

|

Violet Laser Wavelength |

|

Blue Laser Wavelength |

|

Green Laser Wavelength |

|

Yellow Laser Wavelength |

|

Orange Laser Wavelength |

|

Red Laser Wavelength |

|

Near Infrared Laser Wavelength |

|

Short-Wave Infrared Wavelength |

|

Mid-Wave Infrared Wavelength |

|

Long-Wave Infrared Wavelength |

Wavelength:

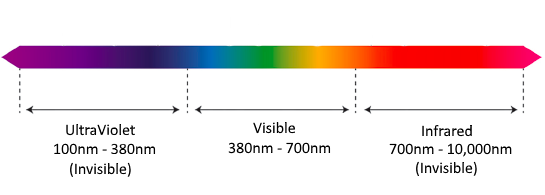

The output wavelength of a laser depends on the laser material, the process of stimulated emission, the optics of the laser resonator, and additional optical components outside the resonator (e.g., non-linear crystals for 2nd, 3rd, 4th, or 5th harmonic generation). As you increase in level of harmonic generation, overall power efficiencies of the laser decrease, as more and more losses are introduced into the system. For each transition between energy levels, a given material can support stimulated emission over a limited range of wavelengths. The probability of stimulated emission varies with wavelengths. The process concentrates emissions at wavelengths with higher stimulated emission probabilities.

Solid-State Lasers and Laser Diodes are available in wavelengths from the deep UV, through Visible and IR, and into the LWIR (long-wave infrared) spectral regions. This laser light wavelength chart provides a quick visual breakdown of UV, Visible, and IR spectral regions.

|

| Wavelengths |

Not all laser types are available in all wavelengths. In many cases, the laser type defines which wavelengths are available.

Laser Diodes:

Laser Diodes are available in many wavelengths from ≈ 370 nm (UV) through 16 µm (LWIR). The wavelengths are determined by the material structure used to make the laser diode. Some of the common Epitaxial materials for laser diode are:

- InGaN – 375 nm – 525 nm

- AlGaInP – 622 nm – 1000 nm

- AlGaAs – 622 nm – 1000 nm

- InGaAsP – 1000 nm – 2100 nm

- GaInAsSb – 1800 nm – 3000 nm

DPSS Lasers:

CW and Pulsed Diode-Pumped Solid-State Lasers are available in a wide range of wavelengths based on the gain medium material. Some of the more common materials and lasing wavelengths are:

- Nd:YAG – 1.064 µm

- Nd:YLF – 1.047 µm and 1.053 µm

- Er:Glass – 1.55 µm

- Er:YAG – 2.94 µm

|

| Second Harmonic Generation |

From the fundamental wavelengths, additional wavelengths can be achieved by frequency doubling or second harmonic generation. For example, the most common diode pumped Nd YAG laser emission wavelength is 1064 nm. From 1064 nm, outputs at 532 nm, 355 nm and 266 nm can be generated by frequency doubling, frequency tripling, and frequency quadrupling, respectively (i.e., 532 nm is the result of a frequency doubled YAG rod @ 1064 nm). Other emission lines for Nd: YAG includes 946nm, 1123 nm, 1319nm, 1338 nm, 1415 nm and 1444 nm. With the proper optimization of these weaker transition lines, one can obtain substantial output power. A great example of these alternate emission lines available from Nd:YAG and Nd:YLF based lasers is our Q-SHIFT Series of shifted wavelength, pulsed DPSS lasers.

Beam and Optical Parameters:

A laser beam has the following important characteristics:

- Directionality: An ordinary source of light emits light waves in all directions and is highly divergent. However, the divergence or angular spread of a laser is very small.

- Monochromaticity: It means that all the laser rays have the same wavelength and frequency when they are emitted from the same source.

- Brightness: A laser beam has brightness many times greater than that of conventional light sources due to the high directional property of a laser beam.

- Coherence: Two or more light waves are said to be coherent if they bear a constant phase relation among themselves.

Laser Diodes:

|

| Laser Diode Emitter Size & Emission Diagram |

Single-mode laser diodes have an emitter that is typically 3µm – 7µm x ≈ 1 um, dependent on the wavelength. The emitter allows only a single mode to propagate along the active region. Single-mode laser diodes offer lower power, but much higher brightness than multimode laser diodes.

Multimode laser diodes have the emitter width enlarged to allow multiple modes in the active region. The emitters can be 30 µm – 300 µm x ≈ 1 um. Multimode laser diodes offer higher output power, but the beam characteristics are not as good.

Free-Space Laser Diodes emit laser light in an ovular or elliptical cone of light that is not collimated. The ellipticity occurs because the divergence is different in the horizontal and vertical directions. Typical values are ≈40° and ≈8° for the two angles of the elliptical cone emitting from Free-Space Laser Diodes. The higher divergence angle is called the fast axis divergence, the lower divergence is called the slow axis divergence. Collimating optics are required to get a collimated output from a laser diode. Collimating the light from a laser diode can be challenging. Fast axis collimating (FAC) lenses and/or Slow axis collimating (SAC) lenses are available on some devices.

Fiber-Coupled Laser Diodes couple the laser light from the laser diode into an optical fiber. Coupling the output of a laser diode into an optical fiber makes delivering light easier. Fiber-Coupled Laser Diodes also have several other advantages:

- The light exiting the fiber has a circular and uniform intensity profile

- It allows the laser diodes and heatsink to be located remotely from where the laser light is used.

- Defective fiber-coupled diode lasers can easily be replaced without changing the alignment of the device where the light is used.

- Fiber-coupled devices can be easily combined with other fiber-optic components.

The output from the fiber is circular but still divergent. The divergence of the output is dependent on the Numerical Aperture (NA) of the fiber.

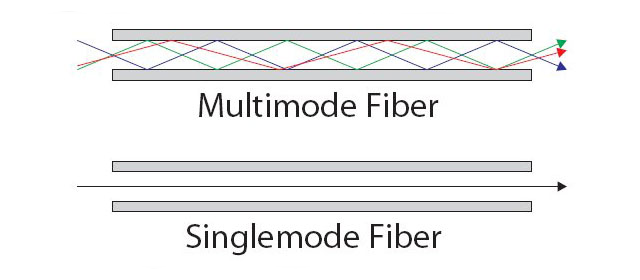

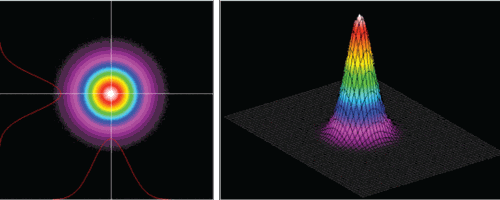

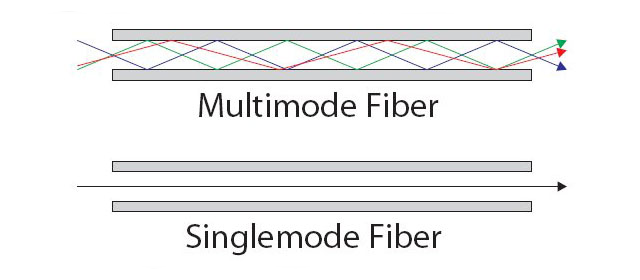

|

| Single-mode versus Multimode |

Both Single-mode and Multimode laser diodes can be fiber-coupled. Single-mode laser diodes can be coupled into single-mode fibers, multimode fibers, or polarization maintaining fibers. Multimode laser diodes can only be coupled into a Multimode fiber.

- Multimode fiber has a larger core diameter and allows multiple modes of light to propagate through the fiber optic. The core diameter can be from 50 µm to over 800 µm. The NA for many multimode fibers is either 0.15 NA or 0.22 NA.

- Single-mode fiber allows only a single mode of light to propagate the length of the fiber. Single-mode fiber typically has a 9 µm core. The standard NA for single-mode fiber is ≈0.12-0.15 NA.

- Polarization maintaining fiber is single-mode fiber that also maintains the linear polarization of the light as it propagates through the fiber. Such fiber is used in applications where preserving polarization is essential.

Fiber Delivery can simplify and add flexibility to your design. Collimating the beam after the fiber is much easier than collimating a free-space laser diode.

Coherence Length – The narrower the range of wavelengths, the more coherent the beam—meaning the more precisely every light wave in the beam is in exact synchronization with every other one. This is measured by a quantity called coherence length. To increase the coherence in a laser diode, typically a grating is required. This grating can be internal or external to the laser diode itself.

- Distributed Feedback (DFB) laser diodes have an internal grating within the active region which locks the wavelength.

- Volume Bragg Grating (VBG) laser diodes use a grating, external to the active region, to lock the wavelength.

CW Lasers & LD Modules:

|

| Module with Collimated Beam |

CW Laser Diode Modules have corrective optics built-in and, typically, single-mode modules deliver a circular, collimated output beam. The divergence angle depends on the collimating optics used. CW DPSS Laser Modules are highly directional with very low divergence. Only waves propagating along the optical axis can be sustained in the cavity, where the laser comes from, which causes the lower divergence. DPSS Laser Modules also have high monochromaticity, brightness, and coherence; all the emitted photons have the same energy, frequency, or wavelength. Hence, the light waves of a laser typically have single wavelength or color and are highly coherent. Because of this coherence, a large amount of power can be concentrated in a small area.

CW Modules typically have either a Plug-and-Play (benchtop / turn-key) version or an OEM version.

- Plug and Play versions typically include a fully CDRH compliant control box that includes the power supply and the safety features required for CDRH compliance.

- OEM versions typically include the laser without the power supply, heatsink, or the control box with CDRH required safety features. OEM modules are intended to be installed or integrated into larger systems including the power supply, thermal management, and CDRH safety features.

Mode – The mode is primarily used to define the type of laser diodes used in the laser diode modules. Single-mode versus multimode laser module:

|

| Single-Mode Beam Profile |

- Single-Mode Modules include the single-mode laser diode modules, both stabilized and un-stabilized, single-mode fiber lasers, and the DPSS Laser Modules. Single mode modules offer the best beam characteristics.

- Multimode Modules utilize a multimode laser diode which offers higher output power, but the beam (typically elliptical) characteristics are not as good. Multimode Green DPSS Lasers are also available.

Fiber-Coupled Modules couple the laser light from the laser diode into an optical fiber. Coupling the output of a laser diode into an optical fiber makes it much easier to deliver light to where it is needed. Fiber-coupled diode lasers also have several other advantages:

- The light exiting the fiber has a circular and uniform intensity profile.

- It allows the laser module and heatsink to be located remotely from where the laser light is used.

- A defective fiber-coupled module can easily be replaced without changing the alignment of the device where the light is used.

- Fiber-coupled devices can be easily combined with other fiber-optic components.

The output from the fiber is circular but still divergent. The divergence of the output is dependent on the Numerical Aperture (NA) of the fiber.

|

| Single mode versus Multimode |

Both Single-Mode and Multimode laser diodes can be fiber-coupled. Single-mode laser diodes can be coupled into single-mode fibers, multimode fibers, or polarization-maintaining fibers. Multimode laser diodes can only be coupled into a Multimode fiber.

- Multimode Fiber has a larger core diameter and allows multiple modes of light to propagate the fiber. The core diameter can be from 50um to over 800um. The NA for many multimode fibers is either 0.15 NA or 0.22 NA.

- Single-Mode Fiber allows only a single mode of light to propagate the length of the fiber. Single-mode fiber typically has a 9um core. The standard NA for single mode fiber is ≈0.12-0.15 NA.

- Polarization-Maintaining Fiber is single-mode fiber that also maintains the linear polarization of the light as it propagates through the fiber. Such fiber is used in applications where preserving polarization is essential.

Fiber Delivery can simplify and add flexibility to your design. Collimating the beam after the fiber is much easier than collimating a free-space laser diode.

Coherence Length – The narrower the range of wavelengths, the more coherent the beam—meaning the more precisely every light wave in the beam is in exact synchronization with every other one. This is measured by a quantity called coherence length.

Many of the CW DPSS Laser Modules can be single longitudinal mode (SLM). SLM CW DPSS Lasers typically have a coherence length >50m.

To increase the coherence in a Laser Diode Module, typically a grating is required. Volume Bragg Grating (VBG) laser diodes use an external grating to lock the wavelength, while Distributed Feedback (DFB) laser diodes use an internal grating. These are usually called stabilized laser diode modules. Stabilized Laser Diode Modules typically have a coherence length of >1m.

Pulsed DPSS Lasers:

Pulsed DPSS Lasers are highly directional with a very low divergence angle. Only waves propagating along the optical axis can be sustained in the cavity, where the laser comes from, which causes the lower divergence. DPSS Laser Modules also have high monochromaticity, brightness, and coherence, all the emitted photons have the same energy, frequency, or wavelength. Hence, the light waves of a laser have single wavelength or color and are highly coherent. Because of this coherence, a large amount of power can be concentrated in a small area.

|

| Laser Pulses |

Pulse width and Repetition Rate: In addition to the beam parameters, pulsed lasers also have a pulse width and repetition rate that needs to be considered. Utilizing pulse generation techniques like mode-locking and active and passive Q-switching, these lasers produce high peak power or high energy pulses with a lower duty cycle by storing energy and releasing then it in pulses. This method is unlike CW lasers and Laser Diodes which emit energy continuously. Pulsed Lasers are available in wide range of pulse widths from femtosecond through millisecond. The repetition rates range from single shot to Mhz.

Active Q-Switched Lasers allow the precise control of both the pulse width and repetition rate of the laser using an on / off system of blocking or emitting photons.

Active Q-Switched Lasers allow the precise control of both the pulse width and repetition rate of the laser using an on / off system of blocking or emitting photons.

- Strengths – Control over pulses, typically higher energy pulses

- Weaknesses – Higher cost, System complexity, much larger than passive

- Passive Q-Switched Lasers contain a Saturable Absorber that, when continuously pumped, produces a regular pulse train. Passive Q-Switch lasers have an increase in pulse to pulse jitter when compared to active q-switched lasers. Passive Q-Switches can be based on a special dye, a passive semiconductor, or a crystal material (typically Cr:YAG).

- Strengths – Lower cost, System simplicity, Compact size

- Weaknesses – Increased pulse to pulse jitter, typically lower pulse energies

- Mode-Locked Lasers (Ultrafast Lasers) produce ultrashort, typically sub-picosecond pulses, at high repetition rates (up to 80 MHz for our current product offerings) by mode locking a large number of phase-locked longitudinal modes from a broadband laser or from a material with a large gain bandwidth.

Pulsed Lasers can have very high energy per pulse. The pulse width of the laser will fall into the following categories:

- Millisecond Lasers – Millisecond Lasers emit pulses in the millisecond (ms) duration and are considered a long-pulse laser. These lasers are used for hair removal, for example. (We do not currently offer any millisecond lasers)

- Nanosecond Lasers –Nanosecond Lasers emit optical pulses in the nanosecond duration. A nanosecond (ns) is a unit of time equal to one thousand-millionth of a second, one billionth of a second, or 10−9 seconds. Optical pulses with a pulse duration in the nanosecond range are required for many applications, including material processing, distance measurements, and remote sensing.

- Picosecond Lasers – Picosecond Lasers are lasers that emit pulses with a duration in the picosecond range. A picosecond is a trillionth of a second, or 10 -12 seconds. To be considered an Ultrafast Laser, the pulse duration of the laser needs to be 10ps or less. At a given pulse energy, the peak power of the laser increases as the pulse width gets shorter. Therefore, a picosecond laser will have a much higher peak power than a longer nanosecond or millisecond pulsed laser.

-

- These higher peak powers result in faster removal rates in a given material because more energy is transferred through the material and less is put into the heating of the material. These high peak power lasers (often several MW pulses) cause a breakdown between the electrons and atoms in the material, creating what is known as a Coulomb explosion.

-

- A Coulomb explosion is a cold processing alternative to the conventional thermal ablation utilized by longer pulsed lasers. In contrast, Ablation is a thermal process that relies on local heating, melting, and vaporization of molecules and atoms…. which can be detrimental to some laser applications. While femtosecond lasers do have their advantages over picosecond lasers, the picosecond laser cost tends to be much more attractive, with high peak powers and high average powers available at a lower price, and a less complicated system.

- Femtosecond Lasers – A Femtosecond laser is a laser which emits optical pulses with a duration below 1 picosecond. A femtosecond (fs) is one quadrillionth of a second or 10−15 seconds. Lasers that produce less than 10 picoseconds pulses belong to the category of Ultrafast Lasers or Ultrashort Pulse Lasers. Ultrafast Lasers are ideal for the non-thermal or cold ablation of any material, including metals, ceramics, polymers, composites, coatings, glass, plastics, diamonds, and PET. Ultrafast lasers can even operate on layered substrates. Cold ablation allows for material to be removed with high precision and without heating the residual matter. Thus, femtosecond fiber lasers will not produce heat affected zones, splatter, or significant recast. Additionally, these lasers will eliminate the need for any post-processing. In recent years, femtosecond fiber lasers have been replacing larger, more complicated ti sapphire lasers. These ultrafast fiber lasers also allow you to place the controller in a rack mount, for example, while positioning the smaller laser head where you need it.

The pulse width and repetition rate are used to define the average power of the laser.

The output from a pulsed laser can be either free-space or fiber-coupled. The primary difference is the free-space output from a pulsed laser typically has a collimated beam, because the laser beam comes from the resonator cavity, and only waves propagating along the optical axis can be sustained in the cavity.

Integration Levels:

Laser Diodes:

Laser Diodes are typically a component level product. There are many levels of integration. Below we list some of the most common:

-

- Unmounted Chips or Bars are the most basic. A laser diode chip or bar is a laser die with the facet coatings. Great care and experience are required to handle the laser diode at this level. The chip or bar can be sold as a package or submount to provide the required thermal and electrical connections.

Packaged Laser Diodes are available in a wide range of packages from a chip on submount, to packages that include optics, thermal management, and fiber coupling. Depending on the amount of waste heat produced, laser diodes packages can dissipate the waste heat by either:

Packaged Laser Diodes are available in a wide range of packages from a chip on submount, to packages that include optics, thermal management, and fiber coupling. Depending on the amount of waste heat produced, laser diodes packages can dissipate the waste heat by either:

- Conductive Cooled devices will require mounting to a heatsink that will conductivity remove the heat from the laser diode. Depending on the amount of waste heat, the heatsink may be very small and simple, or much more elaborate with water cooling.

- Water Cooled devices have the water channels designed in and will require a connection to the appropriate water supply.

- Turn-Key Systems include all the equipment necessary to operate the laser diode and are fully CDRH compliant. The includes the laser diode package, the thermal management, the optical components, and the electrical system for control.

CW Lasers & LD Modules:

CW Modules typically have either a Plug-and-Play (benchtop / turn-key) version or an OEM version.

- Plug-and-Play versions typically include a fully CDRH compliant control box that includes the power supply and the safety features required for CDRH compliance.

- OEM versions typically include the laser without the power supply, heatsink, or the control box with CDRH required safety features. OEM modules are intended to be installed or integrated into a more extensive system that supplies the power, thermal management, and CDRH safety features.

Pulsed Lasers:

Pulsed DPSS Lasers are designed as an OEM component to be used in a system. The system integrator supplies the power, thermal management, beam or sample positioning equipment, and CDRH safety features required for the product.

Have questions?

We are still working on improving this page.

We know this guide is not complete. We will continue to update with additional information as time permits.

If you have any suggestions or ideas on what else we should include, please let us know.

We hope this guide will be a valuable tool for you in the future.

Contact us with the link below or email us today at info@rpmclasers.com to talk to a knowledgeable Product Manager today!

About RPMC:

RPMC Lasers is the leading OEM laser distributor / laser supplier in the US, focused on providing diode lasers, CW and pulsed lasers, laser amplifiers, and laser accessories to the industrial, medical, life science, and defense markets. Our technical staff has over 100 years combined knowledge, a vast understanding of the laser industry, and hands-on technical laser experience, enabling them to find the right laser for their clients, whether it be a standard or custom configuration.

RPMC Lasers was incorporated over 25 years ago to assist LDX Optronics, who develops and manufactures high-quality laser diodes, generate worldwide attention to their products. This partnership allowed LDX Optronics to concentrate on technical challenges and development without the diversion of sales and marketing endeavors. With this successful endeavor came the realization that there is a need for a firm like ours that could add value, reduce costs, and promote growth.

Over time, we have added to our list of laser manufacturers we represent, including industry-leading laser manufacturers in the USA, Europe, and Asia, designing and manufacturing high-quality laser products. While we have exclusive agreements with many of these leading manufacturers, we also partner with other manufacturers to help supply needed solutions to our customer base.

Thanks to the key partnerships we have developed with our manufacturers and customers, as well as the ever-expanding field of laser applications, RPMC Lasers’ growth continues today, offering a wide range of laser products. We are excited about the future and look forward to working with new customers and additional laser manufacturers to continue our mission of finding the right laser for your application!

In addition to the information contained on our knowledge center, we have also organized a detailed list of common laser applications, along with brief descriptions and relevant lasers. To browse the complete list of laser applications, click here, and as always if you don’t see the laser application you’re looking please don’t hesitate to contact one of our applications specialists by clicking the button below or emailing us at info@rpmlasers.com.

Have questions?

SHIPS TODAY

SHIPS TODAY