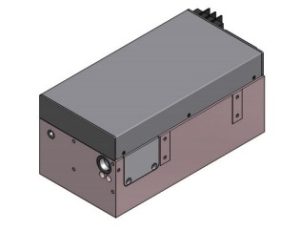

RPMC’s Material Processing & Surface Modification Lasers deliver precision and versatility for demanding industrial applications, from high-speed micromachining to intricate texturing. Offering a range of femtosecond, picosecond, and nanosecond pulsed lasers, our systems excel in cutting, drilling, and non-thermal ablation, ensuring detailed, heat-free processing across materials. With flexible configurations from OEM components to turnkey solutions, these lasers are engineered to optimize production workflows and provide reliable performance under rigorous conditions. Featuring advanced options for pulse rate, power, and beam profile, RPMC’s material processing lasers are indispensable tools for efficient, high-quality material alteration and finishing across industries.

Material Processing & Surface Modification Laser Applications

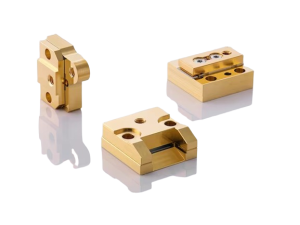

Cutting/Drilling Lasers: Laser cutting and drilling is a process in which q-switched lasers (typically high power, ns pulsed) are used to thermally ablate material to form holes and cuts in various materials, including metals, polymers, ceramics, and more. In both laser cutting and drilling the primary objective is to remove material, and as such, the vaporized material must be allowed to outgas, so that is don’t interfere with the process allowing for precise cuts.

Micromachining Lasers: Laser micromachining is a collection of processes involving sub-millimeter machining of small parts or features on a material using precise and controlled techniques. This subtractive (material removal) process typically involves using specialized micromachining lasers (typically ps or fs pulsed, UV green & IR) to cut, drill, ablate, or otherwise shape materials with accuracy and precision.

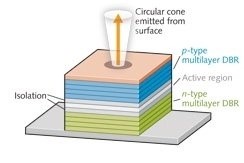

Non-Thermal Ablation Lasers: Non-thermal ablation, often performed using ultrafast lasers, is an advanced method employed to remove material with exceptional precision and minimal heat-induced damage. This technique relies on ultra-short laser pulses (typically ps or fs pulsed) which deliver an intense burst of energy in a fraction of a second, removing material through non-thermal or cold ablation.

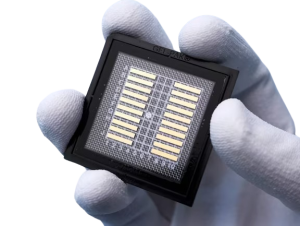

Thin Film Removal Lasers: Laser thin film removal is the process of selectively ablating a very thin layer of material from a substrate, and is widely used on silicon, glass, ceramics, plastics, and metals. These lasers are generally short-pulsed (typically fs, ps or even ns pulsed UV green & IR, high quality TEM00 beam) with the ability to operate at high repetition rates to allow for sufficient pulse overlap at high processing speeds without damaging the substrate.

Marking Lasers: Laser marking is a process of creating permanent marks or patterns on a material’s surface using laser technology. Unlike traditional marking methods like ink printing or engraving, laser marking offers advantages such as high precision, durability, non-contact processing, and the ability to mark a wide range of materials. Laser marking lasers are specifically designed lasers used for the marking process (typically ns or ps pulsed q-switched).

Texturing Lasers: Laser texturing involves engraving the negative image of an intricate design into a mold to produce an end product with a raised decorative patterned surface, allowing molded parts to mimic the look of leather, wood, and other materials. Laser engraving (typically ns or ps pulsed with high quality TEM00 beam) the interior of the mold instead of chemically etching it eliminates the need for hazardous, corrosive chemicals and allows for a completely digitized process.

Let Us Help

With 1000s of fielded units, and over 25 years of experience, providing OEMs, contract manufacturers, and researchers with the best laser solution for their application, our expert team is ready to help! Working with RPMC ensures you are getting trusted advice from our knowledgeable and technical staff on a wide range of laser products. RPMC and our manufacturers are willing and able to provide custom solutions for your unique application.

If you have any questions, or if you would like some assistance please contact us. Furthermore, you can email us at info@rpmclasers.com to talk to a knowledgeable Product Manager.

Check out our Online Store: This page contains In-Stock products and an ever-changing assortment of various types of new lasers at marked-down/discount prices.

We’re experts at helping select the right configuration for you!

SHIPS TODAY

SHIPS TODAY