In a one of last weeks post titled “Understanding Laser Diode Arrays,” we examined how laser diode bars and stacks can be used to generate extremely high-powered direct diode laser sources. In this post, we will look at how these lasers can be used for laser welding in industrial applications when they are fiber coupled and combined to produce multi-kilowatt laser powers out of a single fiber. In order to fully understand the advantages of using these lasers for welding, it is advantageous to look at the differences between the requirements of cutting and welding lasers.

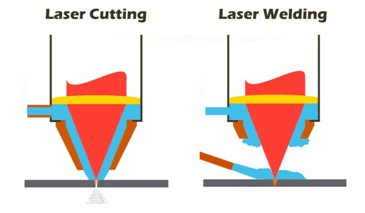

In laser cutting the primary objective is to remove material, and as such, the vaporized material must be allowed to outgas so that is don’t interfere with the process allowing for precise cuts. This is typically accomplished through utilizing a focused gas jet in combination with short laser pulses to prevent vaporized material from building up inside of “cut” which could result in unwanted localized heating and thermal lensing (thermal induced index of refraction variations). On the contrary, in laser welding, the goal is not to remove material but rather melt the material, as a result, a less intense long pulse laser is typically utilized with an unfocused cover gas who’s primary objecting is to prevent oxidation during the welding process. A comparison of the two different setups is shown below, but it is important to point out that for most high-power laser applications reflective systems using off-axis parabolic mirrors are generally preferred due to their lower susceptibility to optical damage and typically there is a replaceable sapphire window which protects the internal optics from external damage.

Another important differentiator between cutting and welding systems is the preferred beam shape. Since in a cutting application the main goal is to have the beam focused to the tightest possible spot, to allow for the highest laser intensity as well as the most precise cut single mode lasers such as fiber lasers are preferred. While on the contrary with welding Gaussian beams are typically avoided, with flat top profiles being preferred for their ability to provide a more uniform power distribution.

From this comparison it is clear that high powered fiber coupled diode lasers are ideal for laser welding. Here at RPMC, we offer fiber coupled direct diode laser systems with up to 3kW of power out of a 600um fiber, by BWT Beijing which is ideal for laser welding applications. This laser system provided a flat top output beam, which is naturally homogenized in the 600um fiber, and user adjustable power and pulse width control through either a touchscreen, RS232, or direct A/D control interface.

For detailed technical specifications on our high power fiber coupled diode lasers from BWT Beijing click here or talk to one of our laser experts today by calling 1-636-272-7227.

SHIPS TODAY

SHIPS TODAY