High Power laser diodes (multimode laser diodes) have an enlarged emitter that allows higher power than single mode laser diodes. The output power varies depending on the wavelength needed. Laser diodes are available in wavelengths from the UV (~370 nm) through the mid IR (>2 um) wavelengths. High power laser diodes are able to reach output powers of many watts in some wavelengths, and just 100’s of milliwatts in other wavelengths. This table defines the maximum output power available at various wavelengths from a single emitter:

| Wavelength | Maximum Output Power per Emitter |

| 300 mW | |

| 1 W | |

| 2.5 W | |

| 700 mW | |

| 1.1 W | |

| 2 W | |

| 8 W | |

| 12 W | |

| 8 W | |

| 8 W | |

| 9 W | |

| 2.7W |

These output powers are based on single emitters. If higher output power is needed, multiple emitters can be used to increase the power. Multiple emitters can be individual emitters optically combined in to a fiber which we call multi emitter packages, or multiple emitters can be produced as a laser diode array or laser diode bar. To learn more about laser diode configurations, see out Lasers 101 page.

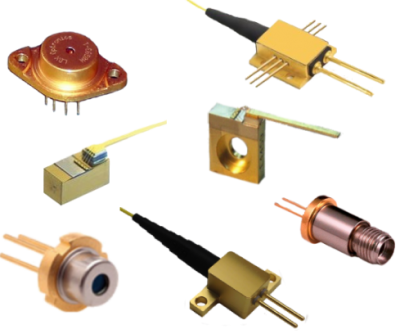

High Power Laser Diode have more waste heat than single mode laser diodes, therefore the package options are different and typically have much better heat sinking capacity. Here are some of the more standard package options:

Free Space Package Options:

C-Mount Package

Features include:

• Industry Standard package

• Small footprint with screw mounting

• Material – Copper (OFHC)

• Fast Axis Lensing Optional

B-Mount Package

Features include:

• Very Small footprint

• Requires Soldering to Heatsink

• Material – Copper Tungsten (CuW)

• Fast Axis Lensing Optional

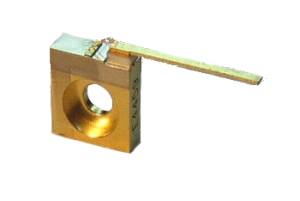

Q-Mount Package

Features include:

• Very Small footprint

• Requires Soldering to Heatsink

• Material – Copper Tungsten (CuW)

• Fast Axis Lensing Optional

Chip on Submount

Features include:

• Very Small footprint

• Requires Soldering to Heatsink

• Material – BeO

• Fast Axis Lensing Optional

9mm package

Features include:

• Industry Standard package

• Hermetically Sealed Windowed package

• Header Material – Copper

• Internal Photodiode Optional

• Isolated Package Optional

• Fast Axis Lensing Optional

TO-3 package Uncooled

Features include:

• Hermetically Sealed Windowed package

• Mounting to Heatsink with screws

• Internal Thermister and Photodiode Optional

• Header Material – Copper

• Fast Axis Lensing Optional

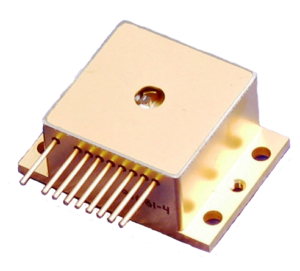

High Heat Load (HHL) package

Features include:

• Hermetically Sealed Windowed package

• Mounting to Heatsink with screws

• Internal Peltier Cooler (TEC)

• Internal Thermister and Photodiode

• Header Material – Copper

• Fast Axis Lensing Optional

Fiber Coupled Packages:

High Heat Load (HHL) package

Features include:

• Hermetically Sealed package

• Fiber Pigtail with SMA connector

• Mounting to Heatsink with screws

• Internal Peltier Cooler (TEC)

• Internal Thermister and Photodiode

• Header Material – Copper

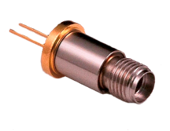

Fiber Coupled 9mm SMA package

Features include:

• Industry Standard package

• Hermetically Sealed package

• SMA connector for Detachable Fiber

• Header Material – Copper

• Internal Photodiode Optional

• Isolated Package Optional

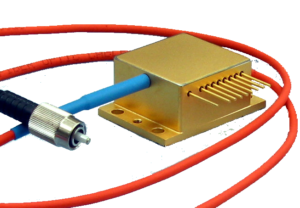

8 pin High Heat Load (HHL) package

Features include:

• Industry Standard package

• Hermetically Sealed package

• Fiber Pigtail with SMA connector

• Header Material – Copper

• Internal Photodiode Optional

• Isolated Package Optional

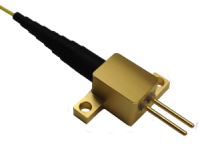

Fiber Coupled 2-pin package

Features include:

• Hermetically Sealed package

• Fiber Pigtail with SMA connector

• Mounting to Heatsink with screws

• Header Material – Copper

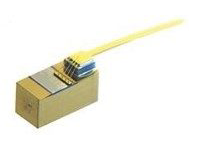

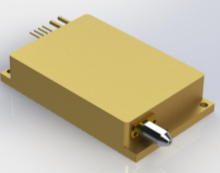

Multi Emitter Packages

Features include:

Features include:

• Packages can handle 2- 20+ emitters

• Hermetically Sealed package

• Fiber Pigtail with SMA connector

• Mounting to Heatsink with screws

• Header Material – Copper

Many other packages are available upon request.

Our line of high power laser diodes is the most complete in the industry. The products range from 375nm to nearly 12 microns in both multi-mode and single mode configurations. We manufacture single emitter diode lasers, laser diode bars, laser diode arrays and multi-element laser diode modules that combine the output from individual emitters. Each type of device is available in both free-space and fiber-coupled configurations.

We also specialize in laser assemblies that offer a combination of the laser, optics, thermal management, and drive electronics. These packages can be customized for the specific application or customer system. This ability allows us to design around specific requirements for your laser diode, whether it be performance, cost, or size.

Many high power laser diode purchasers buy diode-based products and then struggle integrating them into their own systems. A common approach for the system manufacturer is to design the system first and then try to find a laser diode solution that matches the design. They then often experience issues in the following areas:

- Thermal management

- Optics/beam shaping

- Drive control electronics

These problems add cost, impair performance, cause delays, and can put customers in adversarial relationships with their laser diode suppliers. In the worst case, improper specification or integration can mean the difference between a successful prototype or product line and one that either never makes it to production or is out-gunned by a better designed competitive product once it goes to market.

Our Partners develop and produce industry leading high power laser diodes and specialize in the following:

- Epi Wafer Growth and Characterization

- Wafer Processing

- Facet Coating

- Chip and Bar Dicing

- Chip and Bar Testing

- Chip and Bar Packaging

Let RPMC Lasers help you get the best laser for your application.

RPMC Lasers provides laser diodes at an affordable price while providing the best customer service throughout the specification, sales, and implementation process. We believe we are the best option for ALL your DPSS and Laser Diode needs!

See our new Lasers 101 page for in depth information on the attributes of Lasers

SHIPS TODAY

SHIPS TODAY