Laser Diode Fundamentals: Fiber Coupling (Part 2 of 2)

In the last blog post of our laser diode fundamentals series, we discussed the basics of fiber optics concentrating on two key parameters; core diameter and numerical aperture. We mentioned how the numerical aperture depends on the relationship between the index of the core and the cladding, and that this directly relates to the angular acceptance cone of the fiber optic. We also discussed how the core diameter in conjunction with the laser wavelength determines the spatial mode structure of the light guided through the fiber. This is why single mode fiber coupled laser diodes are far more prevalent in the infrared range then they are in the ultraviolet for example, the shorter wavelengths require smaller core diameters. On the flip side when dealing with multi-mode fibers, it is typically ideal to have the core large enough that so many modes can exist that they start to homogenize out and deliver a relatively “flat-top” output. But as the fiber diameter increases the structural integrity of the fiber decreases, making it harder to manipulate. In this blog post, we are going to turn the discussion to fiber coupling techniques conventionally used in laser diode packaging including butt coupling, ball lens coupling, and intermediate collimation.

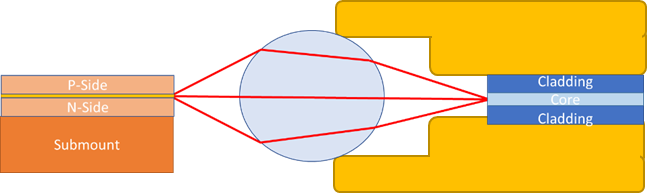

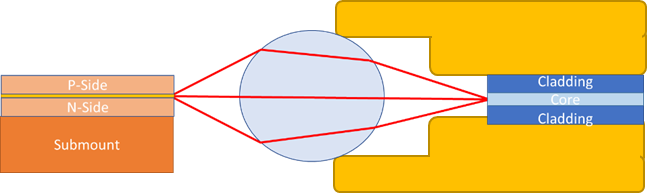

In butt coupling, the proximal end of the fiber optic is aligned using micro-positioning stages while the power output from the distal end in monitored. Once the fiber is positioned in front of the laser facet to maximize the output power of the fiber, the proximal end is secured by either epoxy or spot welding. The diagram below shows a schematic example of how the core of the fiber should be aligned to the laser diodes active area. Butt coupling is the simplest method of laser diode fiber coupling, but also the least efficient because no effort is made to match the fiber’s numerical aperture. Because the laser light emitted from the active area of the diode is highly divergent, the majority of the light falls outside of the cores acceptance angle and ends up in the cladding. This light is known as “cladding modes” quickly leaks out of the fiber, resulting in only a fraction of the light being permanently guided through the fiber. While this approach is extremely inefficient, it is also the least expensive due to the lack of intermediate optical elements. As a result, this method is most commonly used for low-end telecom applications where minimal power is needed.

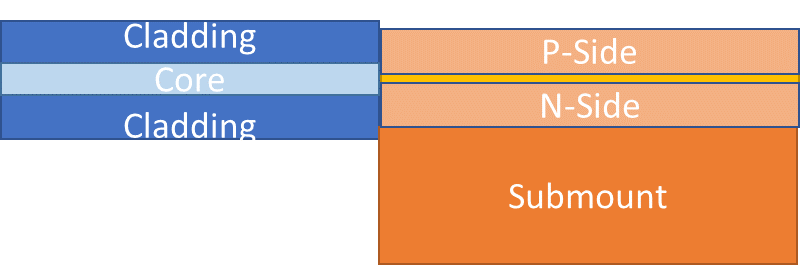

Ball lenses have several unique optical properties which make them highly desirable for as micro-optical elements, with the most significant advantage being their short focal lengths and huge numerical apertures. The mechanical symmetry of the ball lens also makes them extremely easy to align and center. In the diagram below, you can see an example of how a ball lens can be mounted inside of a metal sleeve at the end of a fiber optic cable self-centering it for easy alignment. From this point, the subassembly featuring both the ball lens and the fiber optic can be aligned using a similar process via micro-positioning stages as described with butt coupling. This process dramatically increases the coupling efficiency when compared to butt coupling, but the addition of the ball lens and the mechanical holder add additional cost to the system. While more efficient then butt coupling, ball lenses are far from perfect. The large numerical aperture of the ball lens leads to massive amounts of spherical aberration, which increase the spot size at the proximal end of the fiber which can be problematic for small core diameter fibers. Additionally, ball lenses do not account for the astigmatic nature of diode lasers and can add even more off-axis aberration to the system.

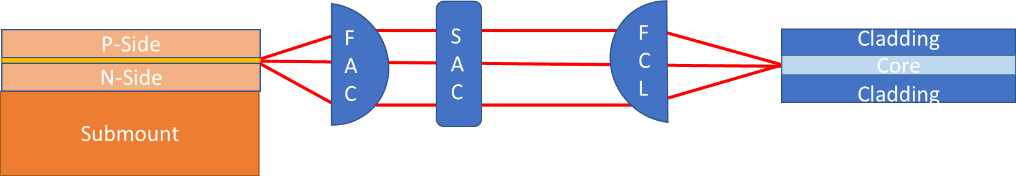

The final fiber coupling geometry that we are going to explore in the blog post is intermediate collimation. This process is achieved through a wide variety of means depending on the desired cost and coupling efficiency. The most straightforward approach is to utilize two ball lenses, one to collimate the laser diode and then one to refocus it into the fiber. While this design makes the micro-positioning of the elements simpler, it doesn’t do much to reduce the aberrations. To eliminate the spherical aberration in this design you can replace the ball lenses with molded aspherical micro-lenses, but in this set-up, there is still the issue of astigmatism. The most effective means of fiber coupling is to use two cross acylindrical micro-lenses for collimation, instead, and one aspherical micro-lens for coupling. For this approach, the first acylindrical lens is matched to the diode’s fast axis (known as the FAC or fast axis collimator) and the second acylindrical lens is matched to the diode’s slow axis (known as the SAC or slow axis collimator). By using two cross lenses, the design is able to eliminate both spherical aberration and astigmatism, but it also dramatically increases the cost and complexity of the overall laser package. This process is ideal when coupling single mode diode lasers into single mode fiber optics, as it will provide the smallest possible spot size.

While there are far more than three different approaches that can be used to fiber coupled laser diodes, these three examples should serve to provide you with the fundamental trade-offs which need to be considered. For low cost, low power application such as telecommunications there is rarely a need for the increased cost and complexity of an intermediate collimator. But when power stability and efficiency are critical as in most analytical applications such as gas sensing and spectroscopy intermediate collimation is the only way to go. Additionally, in high power diode laser applications, the localized heating from poor fiber coupling can cause catastrophic damage over time, reducing the lifetime of the laser package.

Here at RPMC Lasers, we have over 20 years of experience with diode lasers and are readily available to assist you in not only deciding which of our standard off-the-shelf laser diodes are ideal for your application, but we are also able to offer countless custom laser diode packaging configurations with a wide range of integrated optics including all of the designs discussed above. For more information about our wide variety of laser diodes, you can click here, and for more information about laser, diode fundamentals be sure to visit our Lasers 101 page.

SHIPS TODAY

SHIPS TODAY