Laser Diode Fundamentals: Fiber Coupling (Part 1 of 2)

Fiber-coupled diode lasers have become commonplace since the telecom boom of the 1990s, but many people still don’t fully understand the intricacies of the fiber coupling process itself. Fiber optics are widely used in laser technology because of their ability to trap light and guide it from one location to another without experiencing significant loses. But, without understanding the fiber coupling process, it is impossible for someone to know why is it that some fiber-coupled diodes can cost tens of dollars when others can end up costing thousands. While there are countless varieties of fiber optics available on the market today, the two most important factors when discussing how the output of diode laser can be coupled into a fiber are its core size and numerical aperture. Therefore, in this blog post, we are going to first take a brief look at the physical significance of these two parameters, and why they are so crucial to laser diode coupling. In part 2 of this blog post, we will then go on to examine common fiber coupling techniques used in commercial fiber coupled laser diode packaging.

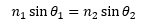

While a detailed analysis of the physical principles behind coupling would require a deep dive into electromagnetic wave theory, which is far beyond the scope of this blog, it is possible to get a first rudimentary understanding of how fiber optics work using the theory of total internal reflection. In geometric optics Snell’s law tells us that whenever light propagates from one medium to another with a different index of refraction, the light will be refracted or bent.

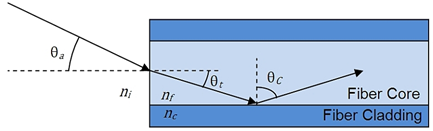

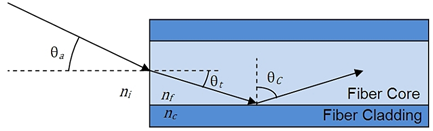

When the mathematical relationship between the incident and refracted angle is taken to the limit where q2 is set equal to 90 degrees, it can be shown that a critical angle exists at which the light will be refracted at such an extreme angle as to be redirected back into the original medium. For the process of total internal reflection to work, the light must be traveling from a medium with a higher index to one with a lower index of refraction. This is why fiber optics are constructed with higher index core and lower index cladding to take advantage of total internal reflection to trap the light inside of the core. The diagram below shows how a ray of light is initially refracted as it enters the core of the fiber optic cable and then as the ray continues to the core-cladding interface it will experience total internal reflection and continue traveling along the length of the fiber as long as the angle of incidence is large enough.

When the mathematical relationship between the incident and refracted angle is taken to the limit where q2 is set equal to 90 degrees, it can be shown that a critical angle exists at which the light will be refracted at such an extreme angle as to be redirected back into the original medium. For the process of total internal reflection to work, the light must be traveling from a medium with a higher index to one with a lower index of refraction. This is why fiber optics are constructed with higher index core and lower index cladding to take advantage of total internal reflection to trap the light inside of the core. The diagram below shows how a ray of light is initially refracted as it enters the core of the fiber optic cable and then as the ray continues to the core-cladding interface it will experience total internal reflection and continue traveling along the length of the fiber as long as the angle of incidence is large enough.

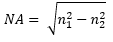

This geometric relationship results in a maximum acceptance angle that ray can enter the fiber and still be guided, without leaking out through the cladding, shown in the image as θa. This angle is primarily dependent on the difference in index of the core and cladding, determines the numerical aperture of the fiber optic accordance to the following equation.

Therefore, it is imperative that any fiber coupling method ensures that the laser beam from the diode must be matched to the numerical aperture of the fiber to efficiently couple. Any rays which do not fall within this angular cone will quickly leak out of the cladding. Since the output of a diode laser is both highly astigmatic and divergent shaping the beam for optimal coupling efficient is far from a trivial task.

Therefore, it is imperative that any fiber coupling method ensures that the laser beam from the diode must be matched to the numerical aperture of the fiber to efficiently couple. Any rays which do not fall within this angular cone will quickly leak out of the cladding. Since the output of a diode laser is both highly astigmatic and divergent shaping the beam for optimal coupling efficient is far from a trivial task.

The next primary parameter that we need to understand is the importance of the core size. Unfortunately, when we start to explore the rationale behind, fiber core diameter, we can no longer rely on geometric approximations. This is because just as we discussed in our February blog post on the fundamentals of laser diode beam properties, depending on the width of the waveguide and the laser wavelength, the fiber can support either one or multiple modes. The underlying physics behind this phenomenon is similar to those discussed in our analysis of longitudinal modes, just applied to different geometries. For example, to maintain a single mode at 1500nm the fibers core diameter must be ~8 microns in diameter, but if you want to support a single spatial mode at 400nm, the core diameter must be closer to 2 microns in diameter. As a result, the shorter the wavelength of the laser, the more difficult it can be to couple it into a single mode fiber.

On the flip side, when dealing with higher power laser application where the multi-spatial mode is acceptable (and often preferred), one would think that by making the core arbitrarily large would be ideal. But, the larger the fiber optic cable, the less flexible it is becoming, which can limit the usefulness of the fiber. As a general rule of thumb, the minimum bend radius of a fiber optic cable is 150 times its cladding diameter. Therefore, when you compare a 105/120 fiber optic with has a core diameter of 105 microns and a cladding diameter of 120 microns it has a bend radius of 1.8 cm whereas a large core fiber such as a 600/750 would have an 11.3 cm bend radius. While there are multimode fibers with even smaller core diameters, such as 50 micron and 62.5 micron core, the 105 micron core has become the industry standard because most multimode laser diodes are constructed with a 100 micron wide ridge waveguide. Since the law of conservation of brightness, also known as étendue, limits the solid angle that the beam can be focused down into so by matching the fiber core diameter to the active area of the diode so coupling efficiency can be maximized.

Now that you have developed an understanding of the basic principles underlying the core diameter and numerical aperture of a fiber optic, in the next blog post for our laser fundamentals series we will explore various commonly used methodologies for fiber coupling laser diodes. In that post, we will then give several examples and discuss their pros and cons, including how they affect the cost and complexity of the end product.

Here at RPMC Lasers, we have over 20 years of experience with diode lasers and are readily available to assist you in not only deciding which of our standard off-the-shelf laser diodes are ideal for your application, but we are also able to offer countless custom laser diode packaging configurations with a wide range of integrated optics include all of the designs discussed above. For more information about our wide variety of laser diodes, you can click here, and for more information about laser, diode fundamentals be sure to visit our Lasers 101 page.

SHIPS TODAY

SHIPS TODAY