Injection molding is a widely used process for rapidly mass-producing low cost highly uniform mechanical parts. On a cursory level, it is a relatively straight forward process by which molten material (metal, glass, polymer, etc.) is injected into a hollowed-out cavity, cooled down to solidify, and then ejected. This results in the material being permanently shaped to the internal cavity of the mold. This process has been around for hundreds if not thousands of years with the original molds being made out of clay and then broken apart to reveal the finished part. Nowadays most molds are made from steel or aluminum (although low-cost rubber molds are also available) and they typically consist of two plates called the injection mold and the ejector mold, which when combined form an internal cavity. These two components are usually manufactured using conventional machining or electrical discharge machining (EDM), but these methods lack the ability to precisely engrave fine details such as text, logos or other patterns. In this blog we will take a look at how a process called laser texturing is used to overcome this limitation, to allow molded parts to mimic the look of leather, wood, and other materials.

Laser texturing is the process of engraving the negative image of an intricate design into a mold to produce an end product with a raised decorative patterned surface. Laser engraving the interior of the mold instead of chemically etching it, not only eliminates the need for hazardous, corrosive chemicals, but it also allows for the process to be completely digitized. This is typically done through standard thermal ablation, where a q-switched laser (typically nanosecond pulse width) is focused onto at the interior surface of the mold cavity and scanned across the surface according to a computer programmed pattern. It is important to note that in some cases mode-locked lasers may be used to facilitate non-thermal ablation when extremely fine detail is required, particularly in medical applications. While texturing lasers can vary in wavelength depending on the mold material, they all need a high quality single spatial mode beam profile, since the size of the focused spot will determine how fine of detail can be textured onto the part.

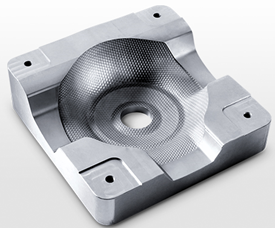

The figure above shows an example of one-half of a mold, where the interior has been textured with a laser to produce a knurled surface. The image below shows another example of a textured mold for manufacturing bottle caps. From that image, you can see both the negative of the GFMS brand on the top and the raised grip around the sides of the cap.

The JenLas® series of nanosecond pulsed fiber lasers from Jenoptik are an ideal laser source for texturing, labeling, marking, cutting, removing, and creating surface structures on plastics and metals. These lasers are specially designed for OEM integration into a piece of industrial equipment and are controlled entirely by interface commands and/or TTL signals. Powered by an industry standard 24-volt supply and air-cooled thermal electric control this laser can be easily integrated into existing tooling or used as the internal engine for developing new texturing equipment.

The JenLas® offers high pulse energy of 1mJ, with pulse repetition rates up to 200 kHz, making it ideal for high-speed machining applications. The reliable, industry-tested fiber laser technology used in this laser series produces pulse duration settings ranging from 190 to 250 nanoseconds, and peak pulse powers of up to 8 kilowatts, with 25 W, 35 W, 55 W, or 105 W average power options. Additionally, these lasers feature advanced optical isolator technology, built-in standard, making them are virtually immune to back reflections.

At RPMC Lasers, we not only offer the JenLas® itself, but we can also provide directly adaptable collimator modules for different beam diameters, as well as a wide range of accessories for optical beam guidance systems in the form of variable beam expanders, F-theta lenses, telecentric lenses – through to entire optical subsystems for integration into machinery. Additionally, we offer certified add-on modules that allow laser sources to be turned off safely by industry standards.

Here at RPMC, we are proud to be the exclusive North American distributor for Jenoptik. If you would like to get additional technical specifications on the JenLas® series of nanosecond pulsed fiber lasers:

Talk to one of our knowledgeable Product Managers today by emailing us at info@rpmclasers.com or Contact Us with the button below!

Have questions?

SHIPS TODAY

SHIPS TODAY