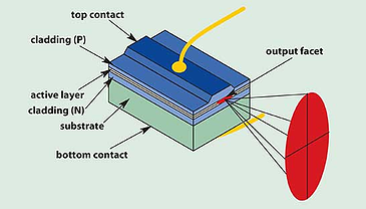

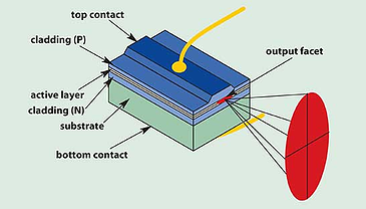

Ever since the industrial fiber laser boom in the early 2000’s, there has been an ongoing debate about the most efficient way to produce high power, fiber-coupled, diode pump lasers. At its root, this debate comes down to the question of single-emitters versus diode bars. While single-emitters cannot come close to the power levels produced by diode bars, typically only producing a few watts of output power, they have several advantages over bars that make them far more desirable for systems integrators. On top of that, they are also far less expensive to fabricate, making them the clear front runner for fiber-coupled pump sources. We have previously published multiple blogs on the material and optical properties of these two types of laser diodes, including “Understanding Laser Diode Arrays” and “Laser Diode Fundamentals: Beam Properties.” So, we will not rehash them here. Instead, in this blog, we are going to focus our attention on why single-emitters are winning out over bars.

To start with, the electrical characteristics of single-emitters are such that they require substantially less current to drive than diode bars. As we discussed in our previous blog titled, “Can I operate multiple laser diodes from the same power supply?” multiple laser diodes can be driven by a single power supply as long as they are connected in series. This means that numerous single-emitters can be put into the same package and operated as if they are a single device. Additionally, the smaller size of single-emitters, compared to bars, results in a much lower parasitic capacitance, which reduces even further when the diodes are connected in series. As a result, single-emitters can be switched on and off at much faster rates than diode bars.

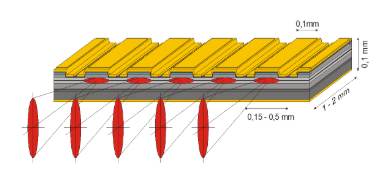

The second significant advantage of single-emitters is their brightness. As a general rule of thumb, you can never increase the brightness of a light source. Brightness is not determined solely by the power, but instead, it is determined by both the power and the size of the active area. This means that you can never focus the beam down smaller than the emitting area of the diode itself. When fiber coupling, single-emitters will be much more efficiently coupled into smaller core fibers, which will allow for more effective pumping of single-mode fiber lasers. When paired with the fact that multiple single-emitters can be driven from the same power supply, we can take advantage of geometric beam combining, to package multiple single-emitters into one package with a co-linear beam, which maintains the brightness of the individual emitters. As a result, these laser sources can be coupled into a single fiber optic which can now quickly produce 10’s to 100’s of watts of output power from a relatively small core multi-mode fiber.

The final consideration worth mentioning when comparing single-emitters to diode bars is thermal management. Since bars run at much higher drive currents that single-emitters, their power consumption is much higher. This results in the generation of far more waste heat than single-emitters. Therefore, most diode bars require far more comprehensive thermal management often including water cooling. Single-emitters on the other hand, produce far less heat and consequently, they can often run with either an air-cooled thermoelectric cooler (TEC), or even at times, with just an uncooled heatsink.

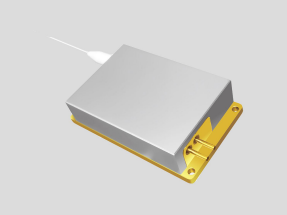

One example of a laser package that utilizes multiple single-emitters combined into a single fiber is the K915FN0RN-130.0W from BWT. This easy-to-integrate OEM laser diode module uses specially designed micro-optics to transform the asymmetric output of the laser chip, improving the beam quality to couple the laser into small core fiber optics, providing 130 watts of power with unprecedented brightness. The K915FN0RN-130.0W high-efficiency laser module comes equipped with a 0.22 NA, 135-micron core, as well as fiber optic pigtail and feedback protection from 1040nm to 1200nm. All of these features make this an ideal pumping laser for ytterbium-doped fiber lasers.

If you would like to get more detailed information on the high-power, fiber-coupled laser diode modules from BWT that are offered here at RPMC Lasers, click here, or you can talk to one of our laser experts today by calling 1.636.272.7227.

SHIPS TODAY

SHIPS TODAY