What Role Can VCSELs Play On The Frontline, Fighting COVID-19?

Despite the recent economic depression caused by the COVID-19 pandemic, the medical industry has seen continued growth. Among the new industry opportunities, demand for medical devices has spiked. In this article, we’ll discuss one device in particular, the pulse oximeter, and the role VCSELs play in enhancing these devices to further support the medical industry and the fight against… Read More

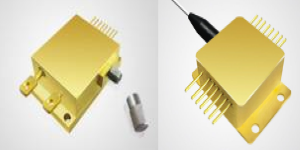

SHIPS TODAY

SHIPS TODAY