RPMC Lasers’ FAQ Page

Buyer may cancel an order at any time prior to shipment by RPMC by delivering written notice to RPMC; provided, however, that Buyer will be responsible for a cancellation charge of 25% of the price of the canceled Products, plus the amount of all direct and indirect costs incurred by RPMC with respect to the canceled order, including without limitation those incurred after receipt of any written cancellation notice.

See our complete Standard Terms and Conditions document.

Cancellation Policy:

Acknowledged Sales Orders may be canceled for any reason, but a cancellation fee may be required.

1) Orders can be partially canceled or canceled in full.

2) Customer is responsible for all work in process and incurred costs.

3) Contact your sales representative or info@rpmclasers.com to start the process.

4) If there is no work in process or incurred costs, the order will be canceled.

5) If there is work in process or incurred costs, RPMC will work with the manufacturer to define these costs and provide the cancellation fee required to cancel the order.

For more information, please visit our full Return and Cancellation Policy or contact us at info@rpmclasers.com.

RPMC itself does not extend a warranty. We are passing along the warranty the manufacturer provides. EXCEPT AS SET FORTH IN A SPECIFIC WARRANTY, RPMC MAKES NO STATUTORY, EXPRESS OR IMPLIED WARRANTY WITH RESPECT TO SUCH PRODUCTS, INCLUDING MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE. See our complete Standard Terms and Conditions document and Return and Cancellation Policy.

Unless otherwise agreed by RPMC and Buyer, the Products are sold F.O.B. shipping point and shipped collect by certified carrier, at buyer’s expense and invoiced, or shipped on Buyer’s carrier account number. If any Products are received by Buyer in a damaged condition, Buyer should cease unpacking such Products, request an immediate inspection by the common carrier responsible for delivery, and furnish the carriers written report to Buyer‘s insurer and to RPMC.

Where a delivery date is specified by RPMC, that date reflects RPMC’s best estimate for the probable time required for completion of Buyer’s order. RPMC will use reasonable and diligent efforts to effect shipment on or before the date indicated. RPMC shall not be liable, directly or indirectly, for any delay or failure in performance or delivery or inability to perform or deliver, including without limitation where such delay, failure or inability arise or results from any cause beyond RPMC’s control or beyond the control of RPMC’s suppliers or contractor, including, but not limited to, strike, boycott or other labor disputes, embargo, governmental regulation, inability or delay in obtaining materials.

IN NO EVENT SHALL RPMC, IN THE EVENT OF DELAYS OR IN ANY OTHER CIRCUMSTANCES, BE LIABLE TO BUYER OR ANY THIRD PARTIES FOR ANY CONSEQUENTIAL, SPECIAL, PUNITIVE OR CONTINGENT DAMAGES, EVEN IF RPMC SHALL BE ADVISED BY BUYER OF THE POSSIBILITY THEREOF.

In the event of any such delay or failure in performance, RPMC shall have such additional time within which to perform its obligations under this Contract as may reasonably be necessary under the circumstances; and RPMC shall also have the right, to the extent necessary in RPMC`s reasonable judgment, to apportion fairly among its various customers in such manner as RPMC may consider equitable Products then available for delivery. If, as a result of any such contingency, RPMC is unable to perform under this Contract in whole or in part, then, to the extent that it is unable to perform, this Contract shall be deemed terminated without liability to either party but shall remain in effect as to the unaffected portion of this Contract, if any.

See our complete Standard Terms and Conditions document.

Price quotations by RPMC are net of delivery charges and taxes, if any, and are valid for thirty (30) days unless a shorter period of time is set forth in such price quotation.

See our complete Standard Terms and Conditions document.

Our complete Standard Terms and Conditions document can be found here. Topics covered include Prices and Quotations, Order Procedure, Governing Law, Price; Taxes, Payment Terms; No Setoff, Delay; Change, Cancellations, and many more.

All quotations express our interest in producing the quoted materials for the Buyer, but the quotation does not guarantee that we will have those materials at a later date. All orders are subject to written acceptance by RPMC unless the order is submitted in response to a firm written offer from RPMC. A Sales Order Acknowledgment executed by a duly authorized RPMC officer shall be deemed a firm written offer from RPMC.

See our complete Standard Terms and Conditions document.

No returned products will be accepted without prior authorization (RMA) from RPMC.

Contact your sales representative, or Customer Service at info@rpmclasers.com.

Any product that has been modified or altered in any way cannot be returned. All returned items must be in brand-new condition, unused (outside of initial qualification), and with their original tags and packaging. The customer is responsible for all return shipping costs.

RPMC will accept returns for the following reasons:

1) Product does not meet the agreed-upon performance criteria / does not work:

A) Contact your sales representative or info@rpmclasers.com to open a ticket and start the process.

B) If the issue cannot be resolved remotely or by a field service technician, an RMA (Return Authorization Request) will be emailed to start the return process.

C) Once the RMA is completed and authorization for the return has been given, the customer is responsible for returning the product to RPMC at their expense.

D) When the device has been received at RPMC and/or the manufacturer, an evaluation and inspection of the stated failure will be performed and shared with the customer.

E) If RPMC finds that the returned product meets all specified requirements and has no failure issues, an evaluation service fee of $500 will be charged to the customer and due before the product is returned.

F) Once RPMC has confirmed the issues related to the return, the customer will be notified, and a repair, replacement, or credit will be offered.

G) A credit that cannot exceed the total amount of the PO, minus our shipping costs, will be issued to the customer’s account.

H) RPMC Lasers can apply any portion of the credit towards the customer’s past-due invoices.

2) Product is not needed / no quality or performance-related issue:

Standard products (excluding Custom or Made-To-Order products) may be returned for credit.

A) Contact your sales representative or info@rpmclasers.com to request an RMA (Return Authorization Request).

B) Once authorization for the return has been given, the customer is responsible for returning the

product to RPMC at their expense.

C) Once the device has been received at RPMC and/or the manufacturer, an evaluation and inspection will be performed.

D) If RPMC finds that the returned product is undamaged and in good working order, a credit will be

issued to the customer’s account, not exceeding the total amount of the PO, minus our shipping

costs and at least a 25% restocking fee.

E) RPMC Lasers can apply any portion of the credit towards the customer’s past-due invoices.

Custom or Made-To-Order products cannot be returned, but we will provide support and repair services.

3) Product failed during warranty period:

The manufacturer’s warranty covers the product against material and workmanship defects within the warranty period. If a defect arises and Customer Service receives a valid claim within the warranty period, we can offer an exchange, repair service, or new components for replacement as defined by the manufacturer.

A) Contact your sales representative or info@rpmclasers.com to open a ticket and start the process.

B) If the issue cannot be resolved remotely or by a field service technician, an RMA (Return Authorization Request) will be emailed to start the return process.

C) Once the RMA is completed and authorization for the return has been given, the customer is responsible for returning the product to RPMC at their expense.

D) When the device has been received at RPMC and/or the manufacturer, an evaluation and inspection of the stated failure will be performed and shared with the customer.

E) If RPMC finds that the returned product meets all specified requirements and has no failure issues, an evaluation service fee of $500 will be charged to the customer and due before the product is returned.

F) Once RPMC has confirmed the issues related to the return, the customer will be notified, and a replacement or repair will be determined.

Cancellation Policy:

Acknowledged Sales Orders may be canceled for any reason, but a cancellation fee may be required.

1) Orders can be partially canceled or canceled in full.

2) Customer is responsible for all work in process and incurred costs.

3) Contact your sales representative or info@rpmclasers.com to start the process.

4) If there is no work in process or incurred costs, the order will be canceled.

5) If there is work in process or incurred costs, RPMC will work with the manufacturer to define these costs and provide the cancellation fee required to cancel the order.

(1) Payment terms are advance payment unless otherwise stated. For firms with no credit history with RPMC, we will require payment prior to shipment.

(2) Any remittances received by a bank or other depository of RPMC in connection with this Contract will be received by such bank or other depository solely as a clearing agency. Such receiving bank or depository has no authority to determine whether or not the amount remitted constitutes payment in full. Remittances marked to indicate “payment in full” or other similar expressions may be deposited by such bank or depository notwithstanding such markings and such deposit shall not indicate RPMC’s acceptance of the remittance as payment in full and shall not otherwise be treated as an election by, or an impairment of any of the rights of, RPMC unless expressly agreed in writing by RPMC.

See our complete Standard Terms and Conditions document.

The same power supply can drive multiple laser diodes if they are connected in series, but they must never be connected in parallel. When two diodes are connected in series, they will function properly as long as the compliance voltage is large enough to cover the voltage drop across each diode. For example, suppose you are trying to power two diode lasers, each with an operating voltage of 1.9 V, and connect the two in series. In that case, the pulsed or CW laser driver must have a total voltage capacity greater than 3.8 V. This configuration works because diodes share the same current when connected in series. In contrast, when two diodes are connected in parallel, the current is no longer shared between the two diodes. Get more details on the topic in this article: “Can I Operate Multiple Laser Diodes From the Same Power Supply?” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

The output wavelength of a semiconductor laser is based on the difference in energy between the valance and conduction bands of the material (bandgap energy). Since the energy of a photon is inversely proportional to its wavelength, this means that a larger bandgap energy will result in a shorter emission wavelength. Due to the relatively wide bandgap energy of 3.4 eV, gallium nitride (GaN) is ideal for the production of semiconductor optoelectronic devices, producing blue wavelength light without the need for nonlinear crystal harmonic generation. Since the mid-’90s, GaN substrates have been the common material utilized for blue LEDs. In recent years, GaN based laser technology has provided blue, green and UV laser diodes, now available in wavelengths from 375 nm to 521 nm, with output powers exceeding 100 watts. Read our article, titled “Gallium Nitride (GaN) Laser Diodes: Green, Blue, and UV Wavelengths” to learn more about GaN Based Laser Diodes, available through RPMC. Get more information from our Lasers 101, Blogs, Whitepapers, and FAQs pages in our Knowledge Center!

Honestly, it depends on several factors, and there is no simple chart to cover everything. Typical diode lifetimes are in the range of 25,000 to 50,000 hours. Though, there are lifetime ratings outside this range, depending on the configuration. Furthermore, there are a wide range of degradation sources that contribute to a shorter lifespan of laser diodes. These degradation sources include dislocations that affect the inner region, metal diffusion and alloy reactions that affect the electrode, solder instability (reaction and migration) that affect the bonding parts, separation of metals in the heatsink bond, and defects in buried heterostructure devices. Read more about diode lifetime and contributing factors in this article: “Understanding Laser Diode Lifetime.” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

There are a great many factors that can increase or decrease the lifetime of a laser diode. One of the main considerations is thermal management. Mounting or heatsinking of the package is of tremendous importance because operating temperature strongly influences lifetime and performance. Other factors to consider include electrostatic discharge (ESD), voltage and current spikes, back reflections, flammable materials, noxious substances, outgassing materials (even thermal compounds), electrical connections, soldering method and fumes, and environmental considerations including ambient temperature, and contamination from humidity and dust. Read more about these critical considerations and contributing factors in this article: “How to Improve Laser Diode Lifetime: Advice and Precautions on Mounting.” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

A Laser Diode or semiconductor laser is the simplest form of Solid-State Laser. Laser diodes are commonly referred to as edge emitting laser diodes because the laser light is emitted from the edge of the substrate. The light emitting region of the laser diode is commonly called the emitter. The emitter size and the number of emitters determine output power and beam quality of a laser diode. Electrically speaking, a laser diode is a PIN diode. The intrinsic (I) region is the active region of the laser diode. The N and P regions provide the active region with the carriers (electrons and holes). Initially, research on laser diodes was carried out using P-N diodes. However, all modern laser diodes utilize the double-hetero-structure implementation. This design confines the carriers and photons, allowing a maximization of recombination and light generation. If you want to start reading more about laser diodes, try this whitepaper “How to Improve Laser Diode Lifetime.” If you want to read more about the Laser Diode Types we offer, check out the Overview of Laser Diodes section on our Lasers 101 Page!

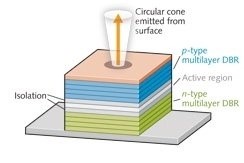

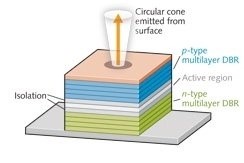

Laser Diodes and VCSELs are semiconductor lasers, the simplest form of Solid State Lasers. Laser diodes are commonly referred to as edge emitting laser diodes because the laser light is emitted from the edge of the substrate. The light emitting region of the laser diode is commonly called the emitter. The emitter size and the quantity of emitters determine output power and beam quality of a laser diode. These Fabry Perot Diode Lasers with a single emission region (Emitter) are typically called laser diode chips, while a linear array of emitters is called laser diode bars. Laser diode bars typically use multimode emitters, the number of emitters per substrate can vary from 5 emitters to 100 emitters. VCSELs (Vertical Cavity Surface Emitting Laser) emit light perpendicular to the mounting surface as opposed to parallel like edge emitting laser diodes. VCSELs offer a uniform spatial illumination in a circular illumination pattern with low speckle. If you want to read more about lasers in general, and help narrowing down the selection to find the right laser for you, check out our Knowledge Center for our Blogs, Whitepapers, and FAQ pages, as well as our Lasers 101 Page!

Within the laser community, one of the most overused and often miscommunicated terms is the phrase “single mode.” This is because a laser beam when traveling through air takes up a three-dimensional volume in space similar to that of a cylinder; and just as with a cylinder, a laser beam can be divided into independent coordinates each with their own mode structure. For a cylinder we would call these the length and the cross-section, but as shown in the figure below for a laser beam, we define these as the transverse electromagnetic (TEM) plane and the longitudinal axis. Both sets of modes are fundamental to the laser beam’s properties, since the TEM modes determine the spatial distribution of the laser beams intensity, and the longitudinal modes determine the spectral properties of the laser. As a result, when a laser is described as being “single-mode” first you need to make sure that you truly understand which mode is being referred to. Meaning that you must know if the laser is single transverse mode, single longitudinal mode, or both. Get all the information you need in this article: “What is Single Longitudinal Mode?” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

Laser alignment can be a challenging task, but aligning a laser beam doesn’t have to be as complicated as it might seem with the right optical alignment tools and proper laser alignment techniques. Multiple optical alignment techniques have been developed over the years, utilized by technicians and engineers to simplify the alignment process. With the development of these universal laser beam alignment methods, along with some laser alignment tips and tricks, you don’t need to be a laser expert to perform your alignments with relative ease, ensuring your laser beam path is right where you want it to be and your beam is on target every time. Read our article, titled “Laser Alignment: HeNe Lasers, Methods, and Helpful Tips” to get the knowledge and advice you need for proper optical beam path alignment utilizing HeNe Lasers. Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

On the surface, this seems like a simple question since Raman is a nonlinear optical effect and therefore the tighter the beam can be focused the higher the conversion efficiency. Seemingly a single-mode laser would be preferable, but in practice there are other factors that can complicate the situation. The first question you should ask yourself when considering which type of laser to choose is whether you are doing microscopy or bulk sampling. If the answer to that question is microscopy, then you immediately should go with a single mode laser. Since the goal of any microscopy system is to produce the highest resolution image possible, the number one consideration should be how tightly can the laser beam be focused down. However, there are several other considerations when choosing between multimode and single-mode. Learn which is best for you in this article: “Multimode vs Single-Mode Lasers for Raman Spectroscopy.” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

A CW or continuous-wave laser is any laser with a continuous flow of pump energy. It emits a constant stream of radiation, as opposed to a q-switched or mode-locked pulsed laser with a pulsed output beam. A laser is typically defined as having a pulse width greater than 250 ms. The first CW laser was a helium-neon (HeNe) gas laser, developed in 1960, which you can read more about in this blog “HeNe Lasers: Bright Past, Brighter Future.” If you want to read more about the types of CW Lasers we offer, check out the Overview of CW Lasers section on our Lasers 101 Page!

It is essential that the laser exhibit a high level of spectral stability, ensuring that any changes in the interference pattern are caused by features in the sample and not originating from the laser beam. In addition to spectral stability, high beam pointing stability ensures consistent measurements by mitigating any beam position drift concerning the position of the sample. Lasers with longer coherence lengths, and subsequently narrower linewidths, play an important role in determining the resolution of the measurement, as well as consideration of the wavelength used. Exhibiting both single longitudinal mode and single spatial mode has excellent benefits. Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

Various LIDAR signal methods for measuring velocity have one critical requirement in common, the need for precise control over laser frequency. While a wide variety of single-frequency lasers have been used in Doppler LIDAR research, the industry as a whole has adopted single-frequency fiber lasers as the ideal light source. Fiber lasers have several advantages over traditional DPSS lasers, all of which derive from the geometry of the fiber optic itself, namely the innate ability to have an extremely long single-mode optical cavity. This geometry allows for the production of either extremely high-power, single-mode lasers producing unprecedented brightness, or extremely narrow band lasers, with near perfect single-frequency output. If you want to learn more about Doppler LIDAR, the critical considerations involved, and ideal laser sources, check out this whitepaper: “Single-Frequency Fiber Lasers for Doppler LIDAR.” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

Within the laser community, one of the most overused and often miscommunicated terms is the phrase “single mode.” This is because a laser beam when traveling through air takes up a three-dimensional volume in space similar to that of a cylinder; and just as with a cylinder, a laser beam can be divided into independent coordinates each with their own mode structure. For a cylinder we would call these the length and the cross-section, but as shown in the figure below for a laser beam, we define these as the transverse electromagnetic (TEM) plane and the longitudinal axis. Both sets of modes are fundamental to the laser beam’s properties, since the TEM modes determine the spatial distribution of the laser beams intensity, and the longitudinal modes determine the spectral properties of the laser. As a result, when a laser is described as being “single-mode” first you need to make sure that you truly understand which mode is being referred to. Meaning that you must know if the laser is single transverse mode, single longitudinal mode, or both. Get all the information you need in this article: “What is Single Longitudinal Mode?” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

A pulsed laser is any laser that does not emit a continuous-wave (CW) laser beam. Instead, they emit light pulses at some duration with some period of ‘off’ time between pulses and a frequency measured in cycles per second (Hz). There are several different methods for pulse generation, including passive and active q-switching and mode-locking. Pulsed lasers store energy and release it in these pulses or energy packets. This pulsing can be very beneficial, for example, when machining certain materials or features. The pulse can rapidly deliver the stored energy, with downtime in between, preventing too much heat from building up in the material. If you would like to read more about q-switches and the pros and cons of passive vs active q-switches, check out this blog “The Advantages and Disadvantages of Passive vs Active Q-Switching,” or check out our Overview of Pulsed Lasers section on our Lasers 101 Page!

There are actually numerous laser types that work well for various LIDAR and 3D Scanning applications. The answer comes down to what you want to measure or map. If your target is stationary, and distance is the only necessary measurement, short-pulsed lasers, with pulse durations of a few nanoseconds (even <1ns) and high pulse energy are what you’re looking for. This is also accurate for 3D scanning applications (given a stationary, albeit a much closer target), but select applications can also benefit from frequency-modulated, single-frequency (narrow-linewidth) fiber lasers. If your target is moving, and speed is the critical measurement, you need a single-frequency laser to ensure accurate measurement of the Doppler shift. If you want to learn more about the various forms of LIDAR and the critical laser source requirements, check out our LIDAR page for a list of detailed articles, as well as all the LIDAR laser source products we offer. Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

Similar to laser hair removal, laser tattoo removal utilizes a process known as selective photothermolysis to target the embedded ink in the epidermis and dermis. Photothermolysis is the use of laser microsurgery to selectively target tissue utilizing specific wavelengths of light to heat and destroy the tissue without affecting its surroundings. In laser tattoo removal this is accomplished by using a focused q-switched laser with a fluence of approximately 10 J/cm2, to heat the ink molecules locally. Since the q-switched laser’s pulse duration (100 ps to 10 ns) is shorter than the thermal relaxation time of the ink molecules it prevents heat diffusion from taking place. In addition to minimizing damage to the surrounding tissue, this rapid localized heating results in a large thermal differential, resulting in a shock wave which breaks apart the ink molecules. If you would like more details on pulsed lasers for tattoo removal applications, see our Aesthetics Lasers page here! Get more information from our Lasers 101, Blogs, Whitepapers, and FAQ pages in our Knowledge Center!

There are a wide variety of q-switch technologies, but the technique as a whole can be broken down into two primary categories of q-switches, passive and active. Active q-switches could be a mechanical shutter device, an optical chopper wheel, or spinning mirror / prism inside the optical cavity, relying on a controllable, user set on/off ability. Passive q-switches use a saturable absorber, which can be a crystal (typically Cr:YAG), a passive semiconductor, or a special dye, and automatically produce pulses based on it’s design. Both passive and active q-switching techniques produce short pulses and high peak powers, but they each have their pros and cons. When choosing between actively q-switched and passively q-switched lasers, the key is to understand the tradeoffs between cost/size and triggering/energy and decide which is best for your particular application. Read more about these tradeoffs in this article: “The Advantages and Disadvantages of Passive vs Active Q-Switching.” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

A laser source used for LIBS must have a sufficiently large energy density to ablate the sample in as short a time possible. Typically, pulsed DPSS lasers take center stage here. However, it’s been shown that pulsed fiber lasers can also be a great option. For example, you could utilize fiber lasers to measure detection limits as low as micrograms per gram (µg/g) for many common metals and alloys, including aluminum, lithium, magnesium, and beryllium. Analytical performances showed to be, in some cases, close to those obtainable with a traditional high-energy Nd:YAG laser. The beam quality of fiber lasers, in conjunction with longer pulse widths, resulted in significantly deeper and cleaner ablation craters. If you want to learn more about LIBS and ideal laser sources, check out either this blog: “OEM Fiber Lasers for Industrial Laser Induced Breakdown Spectroscopy,” or this blog: “Laser Induced Breakdown Spectroscopy (LIBS) in Biomedical Applications.” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

There are many different types of laser designation systems used by the military today. Still, they all share the same basic functionality and outcome. At a glance, the laser requirements seem relatively straightforward. The laser needs to be invisible to the human eye, and it needs to have a programmable pulse rate. Still, when you look in more detail, many small factors add up to big problems if not appropriately addressed. Excellent divergence and beam pointing stability, low timing jitter, and rugged, low SWaP design are all critical features of a good laser designation source. Read more on these critical features in this article: “What are the Critical Laser Source Requirements for Laser Designation?” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

Buyer may cancel an order at any time prior to shipment by RPMC by delivering written notice to RPMC; provided, however, that Buyer will be responsible for a cancellation charge of 25% of the price of the canceled Products, plus the amount of all direct and indirect costs incurred by RPMC with respect to the canceled order, including without limitation those incurred after receipt of any written cancellation notice.

See our complete Standard Terms and Conditions document.

Cancellation Policy:

Acknowledged Sales Orders may be canceled for any reason, but a cancellation fee may be required.

1) Orders can be partially canceled or canceled in full.

2) Customer is responsible for all work in process and incurred costs.

3) Contact your sales representative or info@rpmclasers.com to start the process.

4) If there is no work in process or incurred costs, the order will be canceled.

5) If there is work in process or incurred costs, RPMC will work with the manufacturer to define these costs and provide the cancellation fee required to cancel the order.

For more information, please visit our full Return and Cancellation Policy or contact us at info@rpmclasers.com.

The same power supply can drive multiple laser diodes if they are connected in series, but they must never be connected in parallel. When two diodes are connected in series, they will function properly as long as the compliance voltage is large enough to cover the voltage drop across each diode. For example, suppose you are trying to power two diode lasers, each with an operating voltage of 1.9 V, and connect the two in series. In that case, the pulsed or CW laser driver must have a total voltage capacity greater than 3.8 V. This configuration works because diodes share the same current when connected in series. In contrast, when two diodes are connected in parallel, the current is no longer shared between the two diodes. Get more details on the topic in this article: “Can I Operate Multiple Laser Diodes From the Same Power Supply?” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

The output wavelength of a semiconductor laser is based on the difference in energy between the valance and conduction bands of the material (bandgap energy). Since the energy of a photon is inversely proportional to its wavelength, this means that a larger bandgap energy will result in a shorter emission wavelength. Due to the relatively wide bandgap energy of 3.4 eV, gallium nitride (GaN) is ideal for the production of semiconductor optoelectronic devices, producing blue wavelength light without the need for nonlinear crystal harmonic generation. Since the mid-’90s, GaN substrates have been the common material utilized for blue LEDs. In recent years, GaN based laser technology has provided blue, green and UV laser diodes, now available in wavelengths from 375 nm to 521 nm, with output powers exceeding 100 watts. Read our article, titled “Gallium Nitride (GaN) Laser Diodes: Green, Blue, and UV Wavelengths” to learn more about GaN Based Laser Diodes, available through RPMC. Get more information from our Lasers 101, Blogs, Whitepapers, and FAQs pages in our Knowledge Center!

RPMC itself does not extend a warranty. We are passing along the warranty the manufacturer provides. EXCEPT AS SET FORTH IN A SPECIFIC WARRANTY, RPMC MAKES NO STATUTORY, EXPRESS OR IMPLIED WARRANTY WITH RESPECT TO SUCH PRODUCTS, INCLUDING MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR OTHERWISE. See our complete Standard Terms and Conditions document and Return and Cancellation Policy.

Laser alignment can be a challenging task, but aligning a laser beam doesn’t have to be as complicated as it might seem with the right optical alignment tools and proper laser alignment techniques. Multiple optical alignment techniques have been developed over the years, utilized by technicians and engineers to simplify the alignment process. With the development of these universal laser beam alignment methods, along with some laser alignment tips and tricks, you don’t need to be a laser expert to perform your alignments with relative ease, ensuring your laser beam path is right where you want it to be and your beam is on target every time. Read our article, titled “Laser Alignment: HeNe Lasers, Methods, and Helpful Tips” to get the knowledge and advice you need for proper optical beam path alignment utilizing HeNe Lasers. Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

Unless otherwise agreed by RPMC and Buyer, the Products are sold F.O.B. shipping point and shipped collect by certified carrier, at buyer’s expense and invoiced, or shipped on Buyer’s carrier account number. If any Products are received by Buyer in a damaged condition, Buyer should cease unpacking such Products, request an immediate inspection by the common carrier responsible for delivery, and furnish the carriers written report to Buyer‘s insurer and to RPMC.

Where a delivery date is specified by RPMC, that date reflects RPMC’s best estimate for the probable time required for completion of Buyer’s order. RPMC will use reasonable and diligent efforts to effect shipment on or before the date indicated. RPMC shall not be liable, directly or indirectly, for any delay or failure in performance or delivery or inability to perform or deliver, including without limitation where such delay, failure or inability arise or results from any cause beyond RPMC’s control or beyond the control of RPMC’s suppliers or contractor, including, but not limited to, strike, boycott or other labor disputes, embargo, governmental regulation, inability or delay in obtaining materials.

IN NO EVENT SHALL RPMC, IN THE EVENT OF DELAYS OR IN ANY OTHER CIRCUMSTANCES, BE LIABLE TO BUYER OR ANY THIRD PARTIES FOR ANY CONSEQUENTIAL, SPECIAL, PUNITIVE OR CONTINGENT DAMAGES, EVEN IF RPMC SHALL BE ADVISED BY BUYER OF THE POSSIBILITY THEREOF.

In the event of any such delay or failure in performance, RPMC shall have such additional time within which to perform its obligations under this Contract as may reasonably be necessary under the circumstances; and RPMC shall also have the right, to the extent necessary in RPMC`s reasonable judgment, to apportion fairly among its various customers in such manner as RPMC may consider equitable Products then available for delivery. If, as a result of any such contingency, RPMC is unable to perform under this Contract in whole or in part, then, to the extent that it is unable to perform, this Contract shall be deemed terminated without liability to either party but shall remain in effect as to the unaffected portion of this Contract, if any.

See our complete Standard Terms and Conditions document.

Price quotations by RPMC are net of delivery charges and taxes, if any, and are valid for thirty (30) days unless a shorter period of time is set forth in such price quotation.

See our complete Standard Terms and Conditions document.

Honestly, it depends on several factors, and there is no simple chart to cover everything. Typical diode lifetimes are in the range of 25,000 to 50,000 hours. Though, there are lifetime ratings outside this range, depending on the configuration. Furthermore, there are a wide range of degradation sources that contribute to a shorter lifespan of laser diodes. These degradation sources include dislocations that affect the inner region, metal diffusion and alloy reactions that affect the electrode, solder instability (reaction and migration) that affect the bonding parts, separation of metals in the heatsink bond, and defects in buried heterostructure devices. Read more about diode lifetime and contributing factors in this article: “Understanding Laser Diode Lifetime.” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

On the surface, this seems like a simple question since Raman is a nonlinear optical effect and therefore the tighter the beam can be focused the higher the conversion efficiency. Seemingly a single-mode laser would be preferable, but in practice there are other factors that can complicate the situation. The first question you should ask yourself when considering which type of laser to choose is whether you are doing microscopy or bulk sampling. If the answer to that question is microscopy, then you immediately should go with a single mode laser. Since the goal of any microscopy system is to produce the highest resolution image possible, the number one consideration should be how tightly can the laser beam be focused down. However, there are several other considerations when choosing between multimode and single-mode. Learn which is best for you in this article: “Multimode vs Single-Mode Lasers for Raman Spectroscopy.” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

Our complete Standard Terms and Conditions document can be found here. Topics covered include Prices and Quotations, Order Procedure, Governing Law, Price; Taxes, Payment Terms; No Setoff, Delay; Change, Cancellations, and many more.

There are a great many factors that can increase or decrease the lifetime of a laser diode. One of the main considerations is thermal management. Mounting or heatsinking of the package is of tremendous importance because operating temperature strongly influences lifetime and performance. Other factors to consider include electrostatic discharge (ESD), voltage and current spikes, back reflections, flammable materials, noxious substances, outgassing materials (even thermal compounds), electrical connections, soldering method and fumes, and environmental considerations including ambient temperature, and contamination from humidity and dust. Read more about these critical considerations and contributing factors in this article: “How to Improve Laser Diode Lifetime: Advice and Precautions on Mounting.” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

A CW or continuous-wave laser is any laser with a continuous flow of pump energy. It emits a constant stream of radiation, as opposed to a q-switched or mode-locked pulsed laser with a pulsed output beam. A laser is typically defined as having a pulse width greater than 250 ms. The first CW laser was a helium-neon (HeNe) gas laser, developed in 1960, which you can read more about in this blog “HeNe Lasers: Bright Past, Brighter Future.” If you want to read more about the types of CW Lasers we offer, check out the Overview of CW Lasers section on our Lasers 101 Page!

A Laser Diode or semiconductor laser is the simplest form of Solid-State Laser. Laser diodes are commonly referred to as edge emitting laser diodes because the laser light is emitted from the edge of the substrate. The light emitting region of the laser diode is commonly called the emitter. The emitter size and the number of emitters determine output power and beam quality of a laser diode. Electrically speaking, a laser diode is a PIN diode. The intrinsic (I) region is the active region of the laser diode. The N and P regions provide the active region with the carriers (electrons and holes). Initially, research on laser diodes was carried out using P-N diodes. However, all modern laser diodes utilize the double-hetero-structure implementation. This design confines the carriers and photons, allowing a maximization of recombination and light generation. If you want to start reading more about laser diodes, try this whitepaper “How to Improve Laser Diode Lifetime.” If you want to read more about the Laser Diode Types we offer, check out the Overview of Laser Diodes section on our Lasers 101 Page!

A pulsed laser is any laser that does not emit a continuous-wave (CW) laser beam. Instead, they emit light pulses at some duration with some period of ‘off’ time between pulses and a frequency measured in cycles per second (Hz). There are several different methods for pulse generation, including passive and active q-switching and mode-locking. Pulsed lasers store energy and release it in these pulses or energy packets. This pulsing can be very beneficial, for example, when machining certain materials or features. The pulse can rapidly deliver the stored energy, with downtime in between, preventing too much heat from building up in the material. If you would like to read more about q-switches and the pros and cons of passive vs active q-switches, check out this blog “The Advantages and Disadvantages of Passive vs Active Q-Switching,” or check out our Overview of Pulsed Lasers section on our Lasers 101 Page!

There are actually numerous laser types that work well for various LIDAR and 3D Scanning applications. The answer comes down to what you want to measure or map. If your target is stationary, and distance is the only necessary measurement, short-pulsed lasers, with pulse durations of a few nanoseconds (even <1ns) and high pulse energy are what you’re looking for. This is also accurate for 3D scanning applications (given a stationary, albeit a much closer target), but select applications can also benefit from frequency-modulated, single-frequency (narrow-linewidth) fiber lasers. If your target is moving, and speed is the critical measurement, you need a single-frequency laser to ensure accurate measurement of the Doppler shift. If you want to learn more about the various forms of LIDAR and the critical laser source requirements, check out our LIDAR page for a list of detailed articles, as well as all the LIDAR laser source products we offer. Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

It is essential that the laser exhibit a high level of spectral stability, ensuring that any changes in the interference pattern are caused by features in the sample and not originating from the laser beam. In addition to spectral stability, high beam pointing stability ensures consistent measurements by mitigating any beam position drift concerning the position of the sample. Lasers with longer coherence lengths, and subsequently narrower linewidths, play an important role in determining the resolution of the measurement, as well as consideration of the wavelength used. Exhibiting both single longitudinal mode and single spatial mode has excellent benefits. Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

Similar to laser hair removal, laser tattoo removal utilizes a process known as selective photothermolysis to target the embedded ink in the epidermis and dermis. Photothermolysis is the use of laser microsurgery to selectively target tissue utilizing specific wavelengths of light to heat and destroy the tissue without affecting its surroundings. In laser tattoo removal this is accomplished by using a focused q-switched laser with a fluence of approximately 10 J/cm2, to heat the ink molecules locally. Since the q-switched laser’s pulse duration (100 ps to 10 ns) is shorter than the thermal relaxation time of the ink molecules it prevents heat diffusion from taking place. In addition to minimizing damage to the surrounding tissue, this rapid localized heating results in a large thermal differential, resulting in a shock wave which breaks apart the ink molecules. If you would like more details on pulsed lasers for tattoo removal applications, see our Aesthetics Lasers page here! Get more information from our Lasers 101, Blogs, Whitepapers, and FAQ pages in our Knowledge Center!

There are a wide variety of q-switch technologies, but the technique as a whole can be broken down into two primary categories of q-switches, passive and active. Active q-switches could be a mechanical shutter device, an optical chopper wheel, or spinning mirror / prism inside the optical cavity, relying on a controllable, user set on/off ability. Passive q-switches use a saturable absorber, which can be a crystal (typically Cr:YAG), a passive semiconductor, or a special dye, and automatically produce pulses based on it’s design. Both passive and active q-switching techniques produce short pulses and high peak powers, but they each have their pros and cons. When choosing between actively q-switched and passively q-switched lasers, the key is to understand the tradeoffs between cost/size and triggering/energy and decide which is best for your particular application. Read more about these tradeoffs in this article: “The Advantages and Disadvantages of Passive vs Active Q-Switching.” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

Laser Diodes and VCSELs are semiconductor lasers, the simplest form of Solid State Lasers. Laser diodes are commonly referred to as edge emitting laser diodes because the laser light is emitted from the edge of the substrate. The light emitting region of the laser diode is commonly called the emitter. The emitter size and the quantity of emitters determine output power and beam quality of a laser diode. These Fabry Perot Diode Lasers with a single emission region (Emitter) are typically called laser diode chips, while a linear array of emitters is called laser diode bars. Laser diode bars typically use multimode emitters, the number of emitters per substrate can vary from 5 emitters to 100 emitters. VCSELs (Vertical Cavity Surface Emitting Laser) emit light perpendicular to the mounting surface as opposed to parallel like edge emitting laser diodes. VCSELs offer a uniform spatial illumination in a circular illumination pattern with low speckle. If you want to read more about lasers in general, and help narrowing down the selection to find the right laser for you, check out our Knowledge Center for our Blogs, Whitepapers, and FAQ pages, as well as our Lasers 101 Page!

All quotations express our interest in producing the quoted materials for the Buyer, but the quotation does not guarantee that we will have those materials at a later date. All orders are subject to written acceptance by RPMC unless the order is submitted in response to a firm written offer from RPMC. A Sales Order Acknowledgment executed by a duly authorized RPMC officer shall be deemed a firm written offer from RPMC.

See our complete Standard Terms and Conditions document.

No returned products will be accepted without prior authorization (RMA) from RPMC.

Contact your sales representative, or Customer Service at info@rpmclasers.com.

Any product that has been modified or altered in any way cannot be returned. All returned items must be in brand-new condition, unused (outside of initial qualification), and with their original tags and packaging. The customer is responsible for all return shipping costs.

RPMC will accept returns for the following reasons:

1) Product does not meet the agreed-upon performance criteria / does not work:

A) Contact your sales representative or info@rpmclasers.com to open a ticket and start the process.

B) If the issue cannot be resolved remotely or by a field service technician, an RMA (Return Authorization Request) will be emailed to start the return process.

C) Once the RMA is completed and authorization for the return has been given, the customer is responsible for returning the product to RPMC at their expense.

D) When the device has been received at RPMC and/or the manufacturer, an evaluation and inspection of the stated failure will be performed and shared with the customer.

E) If RPMC finds that the returned product meets all specified requirements and has no failure issues, an evaluation service fee of $500 will be charged to the customer and due before the product is returned.

F) Once RPMC has confirmed the issues related to the return, the customer will be notified, and a repair, replacement, or credit will be offered.

G) A credit that cannot exceed the total amount of the PO, minus our shipping costs, will be issued to the customer’s account.

H) RPMC Lasers can apply any portion of the credit towards the customer’s past-due invoices.

2) Product is not needed / no quality or performance-related issue:

Standard products (excluding Custom or Made-To-Order products) may be returned for credit.

A) Contact your sales representative or info@rpmclasers.com to request an RMA (Return Authorization Request).

B) Once authorization for the return has been given, the customer is responsible for returning the

product to RPMC at their expense.

C) Once the device has been received at RPMC and/or the manufacturer, an evaluation and inspection will be performed.

D) If RPMC finds that the returned product is undamaged and in good working order, a credit will be

issued to the customer’s account, not exceeding the total amount of the PO, minus our shipping

costs and at least a 25% restocking fee.

E) RPMC Lasers can apply any portion of the credit towards the customer’s past-due invoices.

Custom or Made-To-Order products cannot be returned, but we will provide support and repair services.

3) Product failed during warranty period:

The manufacturer’s warranty covers the product against material and workmanship defects within the warranty period. If a defect arises and Customer Service receives a valid claim within the warranty period, we can offer an exchange, repair service, or new components for replacement as defined by the manufacturer.

A) Contact your sales representative or info@rpmclasers.com to open a ticket and start the process.

B) If the issue cannot be resolved remotely or by a field service technician, an RMA (Return Authorization Request) will be emailed to start the return process.

C) Once the RMA is completed and authorization for the return has been given, the customer is responsible for returning the product to RPMC at their expense.

D) When the device has been received at RPMC and/or the manufacturer, an evaluation and inspection of the stated failure will be performed and shared with the customer.

E) If RPMC finds that the returned product meets all specified requirements and has no failure issues, an evaluation service fee of $500 will be charged to the customer and due before the product is returned.

F) Once RPMC has confirmed the issues related to the return, the customer will be notified, and a replacement or repair will be determined.

Cancellation Policy:

Acknowledged Sales Orders may be canceled for any reason, but a cancellation fee may be required.

1) Orders can be partially canceled or canceled in full.

2) Customer is responsible for all work in process and incurred costs.

3) Contact your sales representative or info@rpmclasers.com to start the process.

4) If there is no work in process or incurred costs, the order will be canceled.

5) If there is work in process or incurred costs, RPMC will work with the manufacturer to define these costs and provide the cancellation fee required to cancel the order.

(1) Payment terms are advance payment unless otherwise stated. For firms with no credit history with RPMC, we will require payment prior to shipment.

(2) Any remittances received by a bank or other depository of RPMC in connection with this Contract will be received by such bank or other depository solely as a clearing agency. Such receiving bank or depository has no authority to determine whether or not the amount remitted constitutes payment in full. Remittances marked to indicate “payment in full” or other similar expressions may be deposited by such bank or depository notwithstanding such markings and such deposit shall not indicate RPMC’s acceptance of the remittance as payment in full and shall not otherwise be treated as an election by, or an impairment of any of the rights of, RPMC unless expressly agreed in writing by RPMC.

See our complete Standard Terms and Conditions document.

Various LIDAR signal methods for measuring velocity have one critical requirement in common, the need for precise control over laser frequency. While a wide variety of single-frequency lasers have been used in Doppler LIDAR research, the industry as a whole has adopted single-frequency fiber lasers as the ideal light source. Fiber lasers have several advantages over traditional DPSS lasers, all of which derive from the geometry of the fiber optic itself, namely the innate ability to have an extremely long single-mode optical cavity. This geometry allows for the production of either extremely high-power, single-mode lasers producing unprecedented brightness, or extremely narrow band lasers, with near perfect single-frequency output. If you want to learn more about Doppler LIDAR, the critical considerations involved, and ideal laser sources, check out this whitepaper: “Single-Frequency Fiber Lasers for Doppler LIDAR.” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

A laser source used for LIBS must have a sufficiently large energy density to ablate the sample in as short a time possible. Typically, pulsed DPSS lasers take center stage here. However, it’s been shown that pulsed fiber lasers can also be a great option. For example, you could utilize fiber lasers to measure detection limits as low as micrograms per gram (µg/g) for many common metals and alloys, including aluminum, lithium, magnesium, and beryllium. Analytical performances showed to be, in some cases, close to those obtainable with a traditional high-energy Nd:YAG laser. The beam quality of fiber lasers, in conjunction with longer pulse widths, resulted in significantly deeper and cleaner ablation craters. If you want to learn more about LIBS and ideal laser sources, check out either this blog: “OEM Fiber Lasers for Industrial Laser Induced Breakdown Spectroscopy,” or this blog: “Laser Induced Breakdown Spectroscopy (LIBS) in Biomedical Applications.” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

Within the laser community, one of the most overused and often miscommunicated terms is the phrase “single mode.” This is because a laser beam when traveling through air takes up a three-dimensional volume in space similar to that of a cylinder; and just as with a cylinder, a laser beam can be divided into independent coordinates each with their own mode structure. For a cylinder we would call these the length and the cross-section, but as shown in the figure below for a laser beam, we define these as the transverse electromagnetic (TEM) plane and the longitudinal axis. Both sets of modes are fundamental to the laser beam’s properties, since the TEM modes determine the spatial distribution of the laser beams intensity, and the longitudinal modes determine the spectral properties of the laser. As a result, when a laser is described as being “single-mode” first you need to make sure that you truly understand which mode is being referred to. Meaning that you must know if the laser is single transverse mode, single longitudinal mode, or both. Get all the information you need in this article: “What is Single Longitudinal Mode?” Get more information from our Lasers 101, Blogs, Whitepapers, FAQs, and Press Release pages in our Knowledge Center!

SHIPS TODAY

SHIPS TODAY