Jenoptik Lasers

RPMC Lasers is the Exclusive Source for Jenoptik Lasers’ Products in North America

One of the first and largest photonics companies

-

-

-

-

- Based in Jena, Germany, home of the microscope

-

-

-

Complete OEM laser solution provider:

-

-

-

-

- From wafers to sub-systems and even optics

- Full control over design, assembly, packaging, qualification & more

-

-

-

>25k diode-pumped disk lasers fielded worldwide:

-

-

-

-

- Tried and tested field reliability

-

-

-

What sets Jenoptik lasers apart?

The power of vertical integration

-

-

-

-

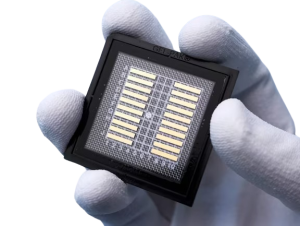

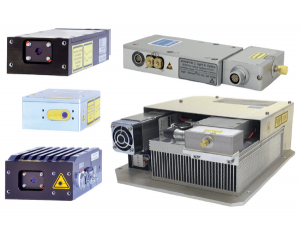

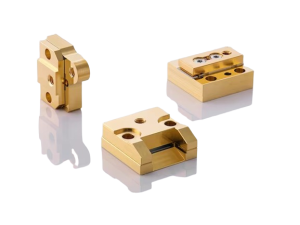

- Complete OEM laser diode provider: You choose the integration level needed from wafers to unmounted diode laser bars to packaged diode lasers to fiber-coupled modules to sub-systems. Full design, packaging, and assembly flexibility

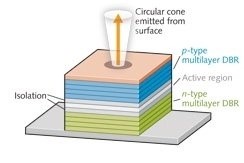

- In-house custom epitaxy & wafer-level processing: 760-1070 nm NIR

- Extensive laser diode packaging capabilities – open heat sinks to passively or actively cooled stacks & housings to fiber-coupled modules

- Field-proven diode-pumped disk lasers

- Your OEM laser integrated solution provider – from wafers to lasers and beyond

-

-

-

Long-standing reputation and dedication to excellence

-

-

-

-

- Industry-leading laser technology, tried & tested w/ rigorous standards

- Experts in diode lasers, DPSS lasers, optics, and system design

- Application & product experts to help develop process/product parameters

-

-

-

Guaranteed international quality standards

-

-

-

-

- ISO 9001 for quality management

- ISO 14001 for environmental management

- ISO 45001 on occupational health & safety

- ISO 27001 for information security

- ISO 13485 for medical devices

-

-

-

Our relationship with Jenoptik goes back nearly 20 years, and we can attest to their quality and extensive range of capabilities in providing complete laser solutions at every level. Whether you need a custom wafer design or a fully integrated laser sub-system with application parameter development, Jenoptik can do it all, in-house. They will give you complete control over the entire process from design to assembly, packaging, qualification, and beyond. Whatever your requirements, Jenoptik will co-develop a tailored solution that fits your needs.

Let us help find the right solution for you!

SHIPS TODAY

SHIPS TODAY