Fiber-Coupled Single Mode Laser Diodes

High-Precision Beam Quality

with Flexible Fiber Delivery

-

-

-

-

-

- Fiber-coupled laser diodes allow for more flexible beam delivery

-

-

-

-

-

-

-

-

-

- Single Mode laser diodes provide higher beam quality

-

-

-

-

-

-

-

-

-

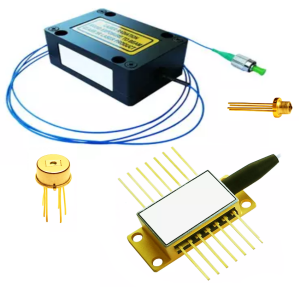

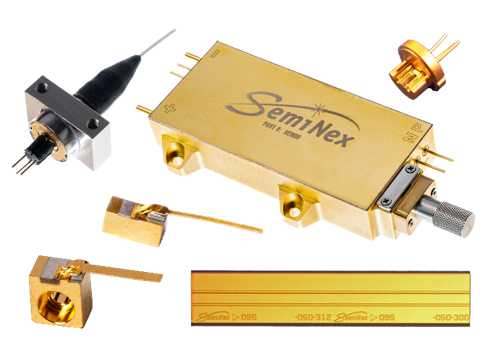

- Wide selection of wavelengths, packages, and integration levels

-

-

-

-

The Fiber-Coupled Single Mode Laser Diodes We Offer:

Fiber-Coupled Laser Diodes Allow for More Flexible Beam Delivery

- Fiber-coupled laser diodes give you flexible beam delivery, long-distance transmission, and simplified integration into fiber-optic systems, especially in telecom, remote sensing, or medical applications. Fiber coupling allows the output to be delivered directly to the work area, as opposed to a free-space output.

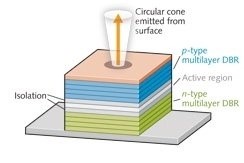

Single Mode Laser Diodes Provide Higher Beam Quality

- Single mode outputs allow for higher beam quality, brightness, and spectral purity. Due to their high spectral purity and stability, single-mode lasers are used in various applications requiring better beam quality but lower output power than multimode laser diodes.

Wide Selection of Wavelengths, Packages & Integration Levels

- Wide selection of wavelengths, packages, and integration levels with both standard and custom options. available in UV to SWIR wavelength regimes. From chips and bars to turn-key systems and every package in between we can find the perfect solution to your needs.

For nearly 30 years, RPMC Lasers has provided the widest selection of semiconductor laser diode wavelengths and packages for various applications in the Defense, Medical, Industrial & Research markets. From standard commercial off-the-shelf components to completely customized solutions, tailored to your specifications from the wafer level, RPMC can deliver the right solution for your needs. Our vast selection of laser diodes is available in UV, violet, blue, green, red, NIR, SWIR, MWIR, and LWIR wavelengths.

With a huge selection of designs and technologies, including single & multi-emitters, arrays (bars) & stacks, quantum cascade lasers (QCLs), triple-junction laser diodes, low noise laser diodes, distributed feedback (DFB) & volume Bragg grating (VBG) laser diodes, and more, we’re sure to have what you need for any application. Whether you need a standard configuration or a completely customized solution with space qualification, RPMC is more than just a provider; we’re your partner, guiding you through the selection process and supporting you from integration to operation, ensuring your long-term success.

SHIPS TODAY

SHIPS TODAY