Important Considerations for 9mm Laser Diode Packages

TO-Can Laser Diode Heat Dissipation

Operating Temperature – Most lasers have a recommended operating temperature and a location where this temperature is measured. Suppose you run a laser diode at a temperature higher than recommended. In that case, the lifetime of the laser will reduce exponentially as the operating temperature increases above the recommended temperature, perhaps to the point of catastrophic failure. Diode laser degradation accelerates with increased temperature. Operating at a temperature lower than recommended for many laser diodes can slightly increase the output power (higher efficiency), improve lifetime, or both. Therefore, one should minimize the operating temperature when feasible. However, lowering the diode laser temperature below 15 °C is only suitable in a hermetically sealed housing with a dry inert atmosphere (e.g., Nitrogen), as condensation will irreversibly damage laser diodes. For example, GaN (gallium nitride) and AlGaN (aluminum gallium nitride) laser diode facets will immediately oxidize when exposed to oxygen.

Read the full article here.

The Three Most Common Mistakes when Mounting and Heatsinking a TO-Can

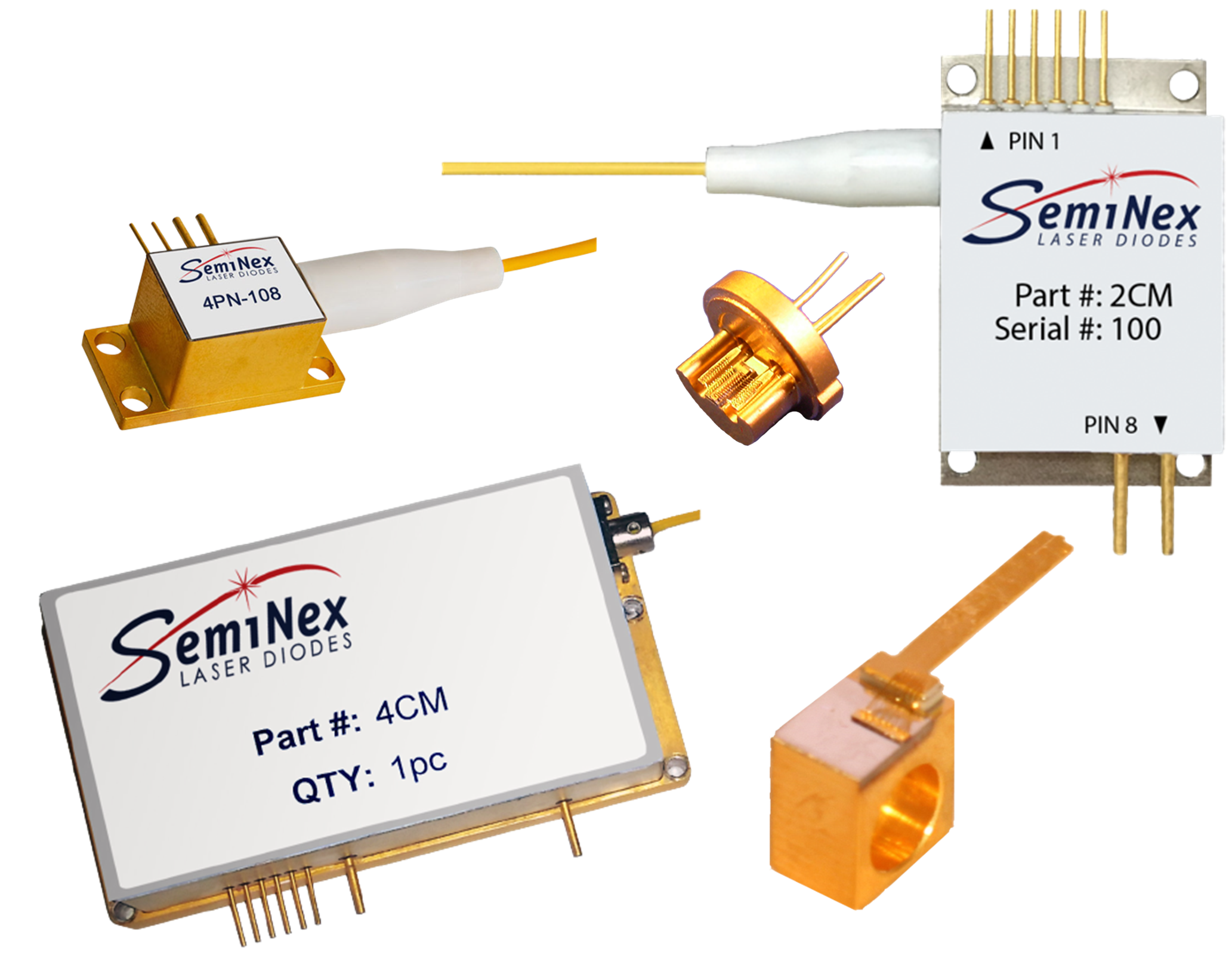

Diode lasers come in a wide variety of packaging configurations. Each package type provides different pros and cons when it comes to beam delivery, heat sinking, integration, and so on. The two most common packages for what we call “component level” diode lasers are the TO-can and the 14-pin butterfly package. While there are some exceptions, in general, the TO-can is the preferred packaging for open beam laser delivery, and the butterfly is preferred for fiber-coupled beam delivery. The TO-can is exceptionally compact, often with an outer diameter less than 10mm, and has beam delivery perpendicular to the base of the package making it extremely desirable to surface mounting applications. But, since the three leads (in some cases, four leads) are underneath the package just like a radial capacitor, this can lead many electrical and packaging engineers to think that it can be treated just like any other through-hole mounted component.

While for some extremely low power and low pointing stability applications, you may be able to get away with basic surface mounting protocols. For most applications, the heat load on the stem of the package requires special care for safe and secure mounting. In this blog post, we are going to discuss the three most common mistakes that people make when mounting and heatsinking a TO packaged laser diode.

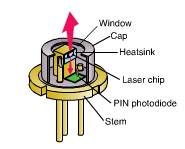

- Always heatsink the stem, never the cap: The most critical factor to understand when mounting a TO-can is that the laser diode is heatsunk to the stem of the package, not to the cap. As you can see from the image above, the laser diode sits on a metal tongue, protruding upward from the base of the package. Both the tongue and stem are typically machined out of a solid piece of a highly conductive metal such as copper tungsten. This way, all of the excess heat produced by the laser chip will flow down the tongue and be dissipated through the much larger stem on the bottom. As a result, there is zero advantage to heatsinking the cap. Instead, all heatsinking should be applied to the base of the package.

Read the full article here.

How Removing the TEC Increases Laser Diode Stability

For most laser diode applications mounting a TEC at the base of the TO-can, or directly under the laser platform in a 14-pin butterfly package, provides enough temperature stability to produce a stable output. But, for high-end applications requiring extremely low noise and extremely long coherence lengths, the TEC itself can end up inducing higher frequency noise.

While on the surface this may sound counter-intuitive, when you take a look at how a standard DC switching power supply works, you will see that they inherently generate high-frequency noise due to the large current swings and the internal inductance and capacitance. In fact, this is the same fundamental principle that most pulse forming networks (PFNs) utilize on a much larger scale to drive the flashlamps in high energy pulsed laser systems. The diagram below shows a simplified example of a typical switching mode DC power supply, which would be used to drive a TEC.

Read the full article here.

How Can We Help?

With over 25 years experience providing 9mm laser diode packages to OEM integrators working in various markets and applications, and 1000s of units fielded, we have the experience to ensure you get the right product for the application. Working with RPMC ensures you are getting trusted advice from our knowledgeable and technical staff on a wide range of laser products. RPMC and our manufacturers are willing and able to provide custom solutions for your unique application.

If you have any questions, or if you would like some assistance please Contact Us here. Furthermore, you can email us at info@rpmclasers.com to talk to a knowledgeable Product Manager.

Alternatively, use the filters on this page to assist in narrowing down the selection of 9mm lasers for sale. Finally, head to our Knowledge Center with our Lasers 101 page and Blogs, Whitepapers, and FAQ pages for further, in-depth reading.

Finally, check out our Limited Supply – In Stock – Buy Now page: This page contains an ever-changing assortment of various types of new lasers at marked-down/discount prices.

Additional Resources

Blogs:

Whitepapers: