Learn More About Unpackaged Laser Diodes

High-power Laser Bars for Optical Pumping and Direct-Diode-Laser (DDL) Applications in Materials Processing, Medicine, or Sensing

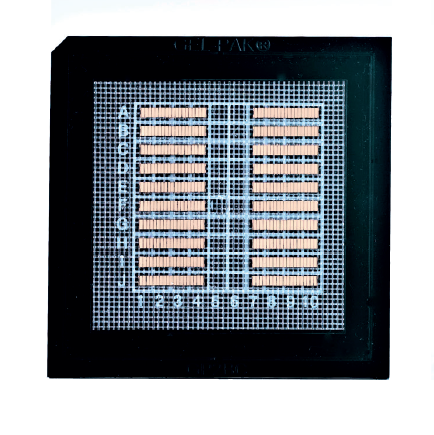

RPMC Lasers provides a wide range of unpackaged laser diode options. Some of these options include wavelengths ranging from 760 nm up to 1060 nm, single-emitter laser diode chips with up to 10 W output power and laser diode arrays / laser diode bars with up to 350 W output power, and continuous wave (CW) and quasi-continuous wave (QCW) options.

We produce our semiconductor materials under the strictest quality controls. We work only with state-of-the-art epitaxy, processing, and facet coating technology. Our bars, semi-bars, and single emitters meet the most exacting demands: They are extremely reliable, efficient, and durable.

Our semiconductor products are easily assembled using standard soldering methods. The material supports both soft solder (indium) and hard solder (gold/tin). We deliver our laser bars to you with emitter structures separated on the p-side as standard. On request, we can also produce bars with continuous p-side metallization and adapted facet coatings, using low AR coatings for the assembly of external resonators.

Correlating with the fill factor we distinguish three product groups for our 10 mm wide bars, each supporting particular applications and operating regimes:

- Low fill factor bars (typ. ≤ 30% fill factor) featuring low beam-parameter-product (BPP) suited for fiber coupling

- High-power bars (typ. 50% fill factor) for up to 300 W cw- and hard-pulse (hp) operation suited for optical pumping and direct-diode-laser (DDL) applications

- QCW bars (typ. FF > 65% fill factor): for up to 500 W qcw- and long-pulse (lp) operation suited for optical pumping and medical applications

Benefits:

- Highest quality: We strictly monitor the production of our semiconductor products in clearly defined processes.

- Powerful: High, reliable output power and ideal beam characteristics.

- Economical: Our semiconductors are very efficient and are characterized by a long service life.

Jenoptik laser diodes are well-known as the high-quality industry standard for medical and industrial applications. Jenoptik is an established company which is present in more than 80 countries. Consequently, their diode lasers are known for their high efficiency and reliability. Finally, to ensure the highest possible quality, long service life, with dependable deliveries, Jenoptik manufactures all laser diodes bars in-house.

Deeper Dive into Unpackaged Laser Diodes

Unpackaged Laser Diode Applications

RPMC has over 25 years of experience providing industry-leading laser diodes, in the widest range of wavelengths, packages, and output powers, to researchers and OEM integrators in the Medical and Industrial markets. We have fielded 10s of thousands of units, from standard, off the shelf products to fully customized laser diode solutions for many applications, including solid-state laser pumping, hair removal, and more! We have the experience and product catalog to ensure we match you with the best laser for your application, and if we don’t have it, we will tell you who does.

- Industry: Semiconductors for high-power diode lasers in direct material processing, for heating or lighting. Semiconductors as pumping sources for fiber and solid-state lasers. Use in printing technology.

- Medicine: Esthetics, dermatology and surgery.

Important Considerations

Blogs:

“Laser Diode Bar Stress“

- As we discussed in our previous application note, when packaging a diode laser, choosing the appropriate solder preform for the die-bonding process is the critical first step for ensuring long term reliability, since the solder joint serves as the primary thermal conductor for heat dissipation. As a result, soft solders such as In are generally preferred because the flexibly of the solder helps to mitigate the stress caused by the mismatch of coefficient of thermal expansion (CTE) between the chip and the submount. An additional benefit of utilizing In solder is the relatively low melting point (157oC), which reduces the thermal load on the diode during the bonding process while soft solder can suffer from greater thermal-fatigue and creep-rupture than hard solders such as AuSn, the risk of cracks in the die or detachment of the die during thermal cycling because of CTE mismatch often out-way any advantages of AuSn…

Whitepapers:

“How to Improve Laser Diode Lifetime: Advice and Precautions on Mounting“

- Over the years, laser diode development has led to increased output power, which is excellent for many applications, except you are now contending with added waste heat. The mounting or heatsinking of the laser package is of tremendous importance because operating temperature strongly influences laser lifetime and performance. Effectively achieving correct mounting or heatsinking of the laser package is not as simple as many would assume. This article will discuss the various package types and the best practices for ensuring the laser diode is mounted correctly. Ensuring the laser diode is mounted correctly will provide the best performance and most extended lifetimes…

How Can We Help?

If you have any questions, or if you would like some assistance please Contact Us here. Furthermore, you can email us at info@rpmclasers.com to talk to a knowledgeable Product Manager.

Alternatively, use the filters on this page to assist in narrowing down the selection of Unmounted lasers for sale. Finally, head to our Knowledge Center with our Lasers 101 page and Blogs, Whitepapers, and FAQ pages for further, in-depth reading.

Finally, check out our Limited Supply – In Stock – Buy Now page: This page contains an ever-changing assortment of various types of new lasers at marked-down/discount prices.

Additional Resources

Blogs:

Whitepapers: