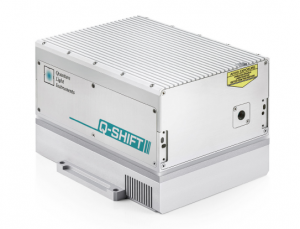

Pulsed Lasers:

Precision, Power & Performance for Every Application

-

-

-

-

- Versatile Pulse Options & High Peak Powers for a Wide Range of Applications

-

-

-

-

-

-

-

- Huge Wavelength Selection – Up to the 5th Harmonic & Tunable Options

-

-

-

-

-

-

-

- Customizable Platforms – Industrial, Medical & MIL-Configured Solutions

-

-

-

The Pulsed Lasers We Offer:

Versatile Pulse Options & High Peak Powers for a Wide Range of Applications

-

- Femtosecond to nanosecond: Cold ablation to LIDAR & everything in between

- Single shot up to 200 MHz rep. rates, fixed & adjustable PRR & pulse width options

- Up to MW range peak powers & nanojoules to 100s of millijoules pulse energy

Huge Wavelength Selection – Up to the 5th Harmonic & Tunable Options

-

- UV (210nm) to Mid-IR (4500nm) range enables many applications in every market

- Up to 5th harmonics allow cost-effective extension of a laser’s capabilities

- Tunable, narrow linewidth & broadband options for spectroscopy, metrology

Customizable Platforms – Industrial, Medical & MIL-Configured Solutions

-

- Configurable pulses, wavelengths, form factor, cooling, add-ons & much more

- Ultrafast fiber to ultra-low SWaP MIL-spec lasers, ruggedized for any environment

- Completely tailored solutions for aerial, space-based, lab or outdoor applications

For almost 30 years, RPMC has delivered cutting-edge pulsed lasers designed to provide unmatched versatility and performance across industries. With femtosecond, picosecond, and nanosecond pulse width options, our lasers offer high peak powers and energy options tailored for a wide range of applications from airborne LIDAR to precision glass processing to advanced research. Spanning wavelengths from UV to Mid-IR, with harmonic generation and tunable configurations, our solutions empower advanced spectroscopy, metrology, and a wide range of scientific and industrial uses.

Whether for high-volume manufacturing, medical applications, or rugged environments, RPMC’s fully customizable platforms ensure seamless integration and reliable operation in the harshest conditions. As your partner, we are committed to helping you find the ideal laser, providing expert guidance and unwavering support throughout your journey.

SHIPS TODAY

SHIPS TODAY