JDL-Unmounted Bars

Laser Diode Bar, 760-1070nm, Unmounted, up to 300 W CW, 500 W QCW

Key Features:

- Full customization starting from the epitaxial level

- Emitter configuration & cavity length options

- Options for Low fill factor, high-power CW & hard-pulse or QCW & long-pulse operation

- High reliability & long lifetime

Get help selecting the right configuration for you!

If you do not see exactly what you need, please contact us!

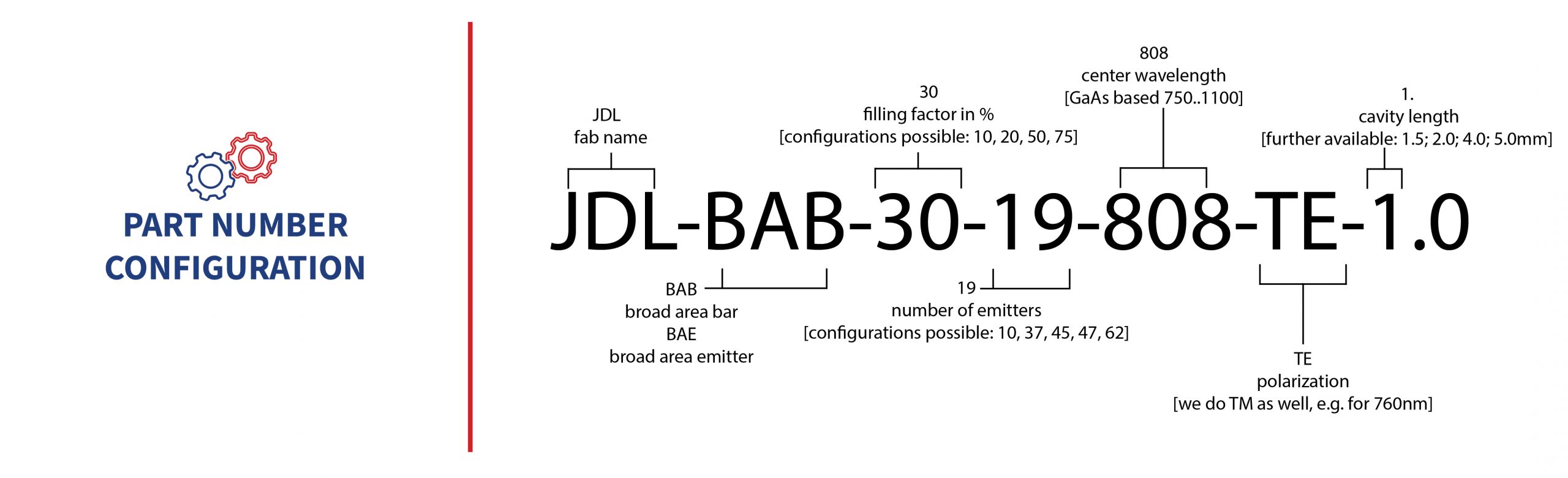

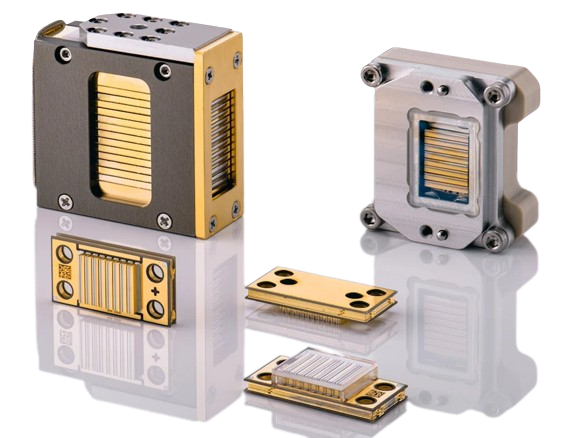

The JDL series offers industry-leading custom high-power unmounted laser diode bars in the 760-1070 nm spectral region. Our unmounted laser diode bars are available in a wide range of emitter configurations, cavity lengths, and CW or QCW operational modes. We offer low fill factor bars suitable for fiber coupling, high-power bars up to 300W for CW or hard-pulse industrial DDL applications, and QCW bars up to 500W for QCW or long-pulse optical pumping and medical applications. With full customization options including custom designed epitaxial wafer structures, you’re sure to get the perfect solution for your needs.

Your OEM Laser Diode Solution Awaits!

Unmounted Laser Diode Bars:

Our 10 mm wide bars come in three distinct laser diode bar product groups based on fill factor, each supporting particular applications and operating regimes

- Low fill factor bars featuring low beam-parameter-product (BPP) suited for fiber coupling (typ. ≤ 30% fill factor)

- High-power bars for up to 300 W CW and hard-pulse (hp) operation suited for optical pumping and direct-diode-laser (DDL) applications (typ. 50% fill factor)

- QCW bars for up to 500 W QCW and long-pulse (lp) operation suited for optical pumping and medical applications (typ. FF > 65% fill factor)

For customers interested in broad-area single emitters, we selectively offer laser bars for cleaving into single emitters and qualification at customer site.

Custom Laser Diode Single-Emitter & Bars Examples Only

Other wavelengths or bar designs available upon request. Let us know what you need!

| Type | Wavelength (nm) | Output power (W) | Emitter Size (µm) | Fill factor | Datasheet |

| Emitter | 760-1070 | 10 | 200 | N/A | JDL-BAE-33-200-808-TM-10-4.0 |

| Bar | 760-1070 | 40 | 150 | 30% | JDL-BAB-30-19-808-TE-40-1.0 |

| Bar | 760-1070 | 200 | 100 | 50% | JDL-BAB-50-23-915-TE-200-4.0 |

| Bar | 760-1070 | 120 | 100 | 50% | JDL-BAB-50-47-940-TE-120-2.0 |

| Bar | 760-1070 | 80 | 100 | 20% | JDL-BAB-20-19-976-TE-80-2.0 |

Let us help choose the right configuration for YOU!

Benefits:

- Industry-Leading Performance: High-power broad-area edge-emitting diode lasers emitting in the 760 nm – 1060 nm spectral region, capable of operating in various modes and up to 300W CW (500 W QCW) optical output power.

- Customization: Variety of emitter configurations and cavity lengths for customization, including custom design epitaxial wafer structures

- Comprehensive Technologies: Comprehensive laser technologies across the entire value chain, from wafer to component, module, optics, and beyond.

- Versatile Applications: Optimized for a wide range of applications in materials processing, medical, or sensing, including optical pumping and direct-diode-laser (DDL) applications.

Epitaxial Wafer Services:

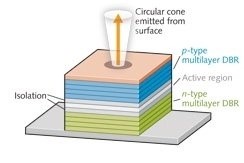

We provide custom design epitaxial wafer structures for a variety of optoelectronic devices operating in the 760-1070 nm spectral range for further wafer-level processing by our customers to produce edge-emitting lasers, surface-emitting lasers (VCELS), LEDs, and photodetectors, for example. Our epitaxial services address the need for Epi-wafer structures based on GaAs substrates and (Al, In, Ga) (As, P) compound semiconductors. We offer strict process and quality monitoring, traceability, confidentiality, and over 20 years of experience in Epi-wafer growth.

In-House Epitaxy and Wafer-Level Processing Capabilities:

Epitaxial wafers can be grown on 3’’, 4’’ or 6’’ GaAs wafers depending on customer request using metal organic chemical vapor deposition (MOCVD). Also known as MPVPE (metal organic vapor phase epitaxy)

- Adjust the Epi-structure:

- fine tune the emission wavelength per the customer-specific packaging technology and the operating conditions

- provide the wavelength divisions required for dense-wavelength-beam-combining (DWBC) applications

- Adjust the facet mirror, e.g. apply low anti-reflection (AR) coatings for applications requiring external feedback

- Apply facet passivation for highest optical output power levels

- Apply custom metallization for In orAuSn based soldering

Don’t hesitate to ask us anything!

| Type | |

|---|---|

| Wavelength (nm) | |

| Output power (W) | |

| Mode | |

| Output | |

| Duty | |

| Package |

SHIPS TODAY

SHIPS TODAY