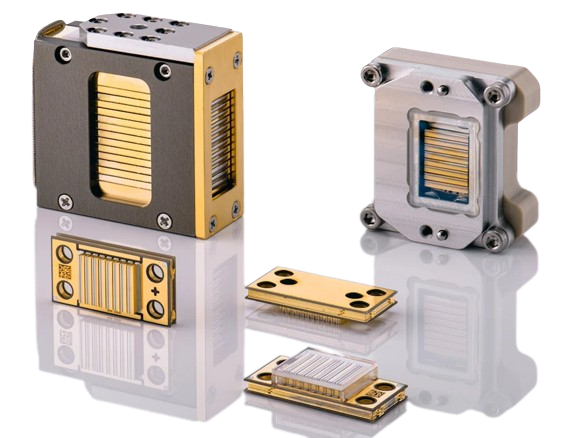

JOLD-Open Heatsinks

Laser Diode Bar Package, 760-1070nm, up to 300 W CW w/ Passive cooling

Key Features:

- High Optical Output Power, up to 300W

- CW & QCW configurations

- High reliability & long lifetime

- FAC or FAC/SAC collimation lensing options

- Passive & active cooling options

- Fully customizable solutions

Get help selecting the right configuration for you!

If you do not see exactly what you need, please contact us!

The JOLD-Open Heatsinks Series offers industry-leading, reliable, and cost-effective high-power free-space single-laser-bar packages based on passively or actively cooled heat sinks in the 760-1070 nm range. Our proprietary heat sink and assembly technology, paired with our focus on advanced optical pumping and direct-diode-laser technology, results in diode lasers with unmatched performance including optical output power, electro-optical (EO) efficiency, and lifetime. This series offers options from 792 nm up to 1035 nm, and average output powers up to 300 W CW with passive cooling.

Your OEM Laser Diode Solution Awaits!

Many configuration options available:

- Wavelength: Options from 760-1070 nm

- Optical output power: up to 300 W

- Operating mode: CW or QCW

Cooling Options:

- Passively cooled heat sinks, i.e. single-bar packages which conductively spread and transfer dissipated power to a baseplate before waste heat is ultimately removed, e.g. via tap water cooling of the baseplate

- Actively cooled heat sinks i.e. single-bar packages which are directly cooled with water in order to convectively remove the heat directly from the heat sink

- Active cooling allows for a smaller and narrower heat sink design which still make this heat sink technology an attractive building-block for densely packed horizontal arrays serving e.g. side-pumping applications

Packaging Options:

While still supplying industry standard heat sink designs (CS, CT) and established assembly technologies based on In or AuSn soldering, Jenoptik is leveraging our proprietary, cutting-edge heat sinking and die attach technologies within our double-side passively cooled packages CN, LS and LK in order to serve most advanced optical pumping schemes and direct-diode-laser (DDL) technology.

Close cooperation between our in-house laser bar fab and our laser assembly site ensures a laser bar tailored to the specific heat sink technology, operating parameters, and application specific needs.

Lensing Options:

- Beam collimation using microlenses.

- Beam shaping using diffractive optical elements (DOE).

Open Heatsink Examples

Other wavelengths, heat sink variants, and configurations upon request. Let us know what you need!

| Output Power (W) | Operation Mode | Cooling | Collimation | Heatsink | Datasheet |

| 55 | CW | Passively cooled | Fast axis | CS | JOLD-55-CPFN-1L |

| 60 | CW | Passively cooled | Without | CS | JOLD-60-CPNN-1L |

| 80 | CW | Actively cooled | Without | CT | JOLD-80-CANN-1L |

| 300 | QCW | Passively cooled | Without | CS | JOLD-300-QPNN-1L |

| 80 | CW | Passively cooled | Without | CS | JOLD-80-CPNN-1L |

| 180 | CW | Passively cooled | Fast axis | CN | JOLD-180-CPFN-1L |

| 200 | CW | Passively cooled | Without | CN | JOLD-200-CPNN-1L |

| 100 | CW | Passively cooled | Without | CS | JOLD-100-CPNN-1L |

| 160 | CW | Passively cooled | Without | CN | JOLD-160-CPNN-1L |

| 300 | CW | Passively cooled | Without | LK | JOLD-xxx-CPNN-1L |

Let us help choose the right configuration for YOU!

Benefits:

- Superior Performance:

- Proprietary heat sink and assembly technology

- Industry-leading optical output power, electro-optical (EO) efficiency, and lifetimes

- Reduced cost of ownership through reliable laser solutions

- High-Volume Manufacturing and Pioneering Experience:

- Pioneering experience in high-volume manufacturing

- Assembly technologies based on In or AuSn soldering

- Consistent quality and faster delivery times for customers

- Cutting-Edge Technologies:

- Proprietary, cutting-edge heat sinking and die attach technologies

- Expertise in introducing AuSn-soldering in the field

- Superior beam quality, increased efficiency, and higher output powers

- Tailored Solutions:

- Customized package solution tailored to specific needs and requirements

- Laser bars tailored to the specific heat sink technology, operating parameters, and application specific needs

- Reduced Cost of Ownership:

- Reliable laser solutions that require minimal maintenance and downtime

- Reduced cost of ownership over the lifetime of the laser system

The JOLD-Open Heatsinks Series offers a range of benefits that make it the ideal choice for those seeking the best in diode laser technology. With a focus on superior performance, the company’s proprietary heat sink and assembly technology ensures high-quality and reliable laser systems that are optimized for a desired wavelength and performance. Jenoptik can tailor solutions to meet your specific needs and requirements, and their reliable laser solutions require minimal maintenance and downtime, resulting in reduced cost of ownership over the lifetime of the laser system.

The most critical part in diode laser selection is not optical output power but optical output power at a well-defined reliability point required by the application. Whether you focus on maximizing optical power at the expense of lifetime or maximizing lifetime at de-rated optical power conditions – we will support you in making the right product selection.

Don’t hesitate to ask us anything!

Advanced LK Heat Sink Technology

Take advantage of our industry-leading open heat sink diode laser product technology, LK. This technology translates the increased power from each mounted laser bar into a simpler system, reducing the overall cost of ownership. This is beneficial whether your application involves optical pumping or DDL technology.

Our state-of-the-art laser bars, when combined with our latest advancements in die-mounting and assembly technology, can achieve optical output power levels of up to 300 W in both continuous wave (CW) and hard-pulse modes. This is possible in the 9XX nm region. With Jenoptik, you’re always at the cutting edge of technology.

Learn more about LK Heat Sink Technology HERE!

| Type | |

|---|---|

| Wavelength (nm) | |

| Output power (W) | |

| Mode | |

| Output | |

| Duty | |

| Package | CS, CN, LK Package |

SHIPS TODAY

SHIPS TODAY