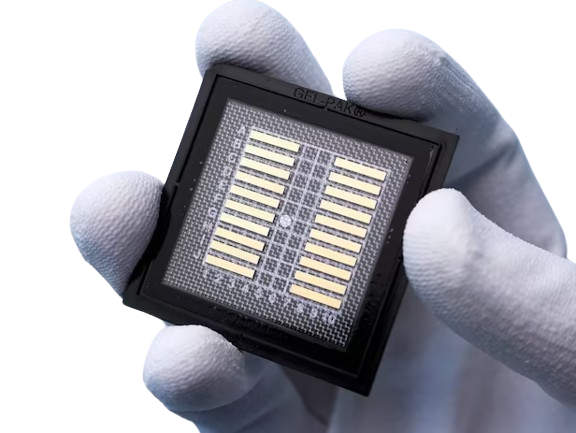

JOLD-Stacks

Laser Diode, Multimode, Bar stack, Infrared, 760-1070nm, up to 2400W

Key Features:

- Scalable output power up to 2400W

- CW & QCW configurations

- High reliability & long lifetime

- FAC or FAC/SAC collimation lensing options

- Passive & active cooling options

- Fully customizable solutions

Get help selecting the right configuration for you!

If you do not see exactly what you need, please contact us!

The JOLD–Stacks Series offers a highly modular approach for power scaling well into the kW range. The series features compact, lightweight, and robust multimode, free-space laser diode stacks with options for 760-1070 nm, CW & QCW operation, output power up to 2400 W (QCW), no lensing or FAC or FAC/SAC collimation, active or passive cooling, and are completely customizable. JOLD-Stacks achieve optimal beam quality by reducing the stack pitch without compromising cooling capacity, and our proven hard-solder technology and strictly monitored production processes ensure tried & tested reliability in the harshest environments.

Your OEM Laser Diode Solution Awaits!

Many configuration options available:

- Wavelength: Options from 760-1070 nm (multi-wavelength stacks available for “color mixing”)

- Optical output power: number of bars per stack

- Operating mode: CW or QCW/long-pulse

- Cooling: active with DI or tap water or passive/conductive

- Packaging: with or without housing and protective window option

- Lensing: FAC or FAC/SAC lensing available

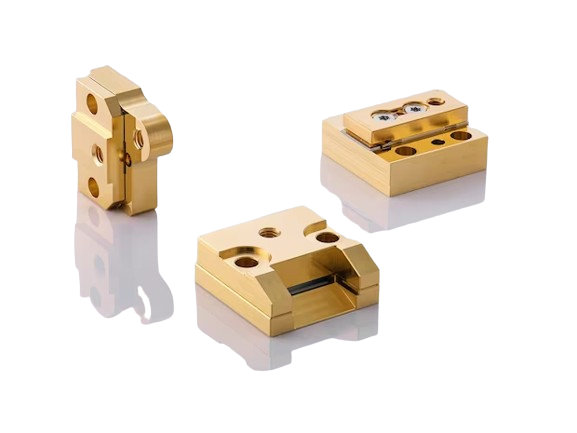

Passively Cooled Stacks:

QCW- and long-pulse configurations utilize vertical stacks made up of CTE-matched submounts on Direct-Copper-Bonded (DCB) substrates. This type of vertical stack clearly offers several advantages:

- Tap water or passive cooling of the DCB

- Light-weight

- Small footprint

- Compact multi-stack arrangements offering additional power scaling (multi-stack packages)

- Ideal for Medical applications like laser-based therapy for ophthalmology, dermatology, and esthetics

Passively Cooled QCW Stack Examples

Other wavelengths, heat sink variants, and configurations upon request. Let us know what you need!

| Wavelength (nm) | Output Power (W) | Operation Mode | Cooling | Collimation | Datasheet |

| 808 | 1560 | QCW | Passive | Fast axis | JOLD-1560-QAF-2x8A-med |

| 808 | 1600 | QCW | Passive | Without | JOLD-1600-QA-2x8A-med |

| 808 | 2160 | QCW | Passive | Without | JOLD-2160-QF-8A |

| 808 | 2400 | QCW | Passive | Without | JOLD-2400-Q-8A |

| 808 | 2400 | QCW | Passive | Without | JOLD-2400-QA-8A-industry |

| 940 | 2160 | QCW | Passive | Without | JOLD-2160-QF-8A |

| 940 | 2400 | QCW | Passive | Without | JOLD-2400-Q-8A |

| 940 | 2400 | QCW | Passive | Without | JOLD-2400-QA-8A-industry |

Let us help choose the right configuration for YOU!

Actively Cooled Stacks:

Microchannel-cooled packages (MCCP) which are actively cooled with DI water for CW-operation, utilizing best-known practices regarding microchannel designs, DI-water specification, and cooling circuit maintenance, enabling package-limited lifetimes > 10k hours – relevant for industrial applications:

- DI-water cooling for MCC packages

- Light-weight

- Small footprint

- Compact multi-stack arrangements offering additional power scaling (multi-stack packages)

- Ideal for Material Processing & DDL applications like welding, soldering, hardening, and annealing

Actively Cooled CW Stack Examples

Other wavelengths, heat sink variants, and configurations upon request. Let us know what you need!

| Wavelength (nm) | Output Power (W) | Operation Mode | Cooling | Collimation | Datasheet |

| 808 | 360 | CW | Active | Fast axis | JOLD-360-CAFN-8A |

| 808 | 400 | CW | Active | Without | JOLD-400-CANN-8A |

| 808 | 576 | CW | Active | Fast axis | JOLD-576-CAFN-8A |

| 808 | 600 | CW | Active | Without | JOLD-600-CANN-12A |

| 808 | 640 | CW | Active | Without | JOLD-640-CANN-8A |

| 808 | 800 | CW | Active | Without | JOLD-800-CANN-10A |

| 808 | 960 | CW | Active | Without | JOLD-960-CANN-12A |

| 940 | 440 | CW | Active | Fast axis | JOLD-440-CAFN-4A |

| 940 | 480 | CW | Active | Without | JOLD-480-CANN-4A |

| 940 | 660 | CW | Active | Fast axis | JOLD-660-CAFN-6A |

| 940 | 720 | CW | Active | Without | JOLD-720-CANN-6A |

| 940 | 1080 | CW | Active | Fast axis | JOLD-1080-CAFN-12A |

| 940 | 1200 | CW | Active | Without | JOLD-1200-CANN-12A |

Let us help choose the right configuration for YOU!

Benefits:

- Modular Power Scaling:

- Vertical stacking of individual sub-mounts within multi-laser-bar packages

- Highly modular approach for power scaling well into the kW-range

- Flexibly scale-up a laser stack to the requested power level at a given center wavelength

- Optimized Beam Quality:

- Beam quality (beam-parameter-product, BPP) optimized with lowest pitches

- Neighboring stack distance approaching 1.0 mm without compromising on cooling capacity of the submounts

- Proven Reliability:

- Tried & tested under application-specific conditions ranging from medical, industrial to mission-critical end use

- Proven hard-solder technology that covers even the harshest environmental conditions

- Strictly monitored production in clearly defined processes based on certifications

- Customization and Design Flexibility for Comprehensive Solutions:

- Tailored solutions to meet your unique application requirements

- Reliable laser solutions, providing you with the specifications you need

- From wafer to component, module, and beyond – let us know what you need!

Don’t hesitate to ask us anything!

| Wavelength (nm) | |

|---|---|

| Description | Laser Diode, Multimode, Bar stack, Infrared, 760-1070nm, up to 2400W |

| Type |

SHIPS TODAY

SHIPS TODAY