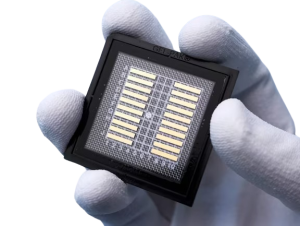

The Laser Diode Arrays We Offer:

Powerful & Highly-Scalable Designs

-

- Output powers up to 2400W, supporting CW & QCW output

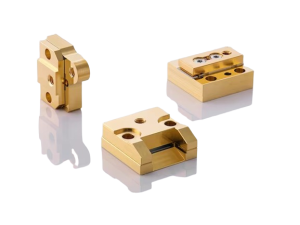

- Unmounted or w/ conductively/actively cooled packages for enhanced thermal management

- Complete control over entire process: design to assembly, packaging, qualification & beyond

Customizable Configurations with Wide Wavelength Range

-

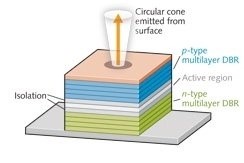

- 760-1470nm wavelengths supporting various material processing & medical applications

- Fill factor, emitter pitch & array length are customizable based on required performance

- Configurable to meet specific requirements – free-space & fiber-coupled package options

Flexible Integration & Application Versatility

-

- Easily integrates with both free-space and fiber-coupled setups

- Supports various modes and power levels for diverse apps

- Offers adjustable beam shapes and sizes to meet specific needs

For nearly 30 years, RPMC’s selection of Laser Diode Arrays (Bars) has set the standard for affordable precision across a wide range of applications, from defense to medical, industrial, and research with 1000’s of successful units in the field. We understand that every application has unique requirements, which is why our configurable platforms are designed to offer the perfect fit for your needs. As your partner, we’re here to guide you through the selection process, ensuring that your array integrates seamlessly into your existing systems. With time-tested technology that balances power and precision, we’re committed to supporting your success every step of the way.

SHIPS TODAY

SHIPS TODAY