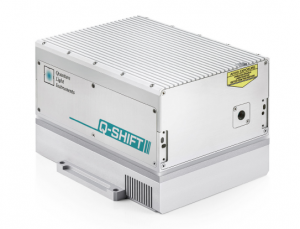

The Low Jitter Lasers We Offer:

Ultra-Stable Pulse Timing with Minimal Pulse Jitter

-

- Accurate and consistent pulse timing, critical for precise applications

- Minimizes timing variations, providing consistent, reliable performance

- Errors can be reduced five times down to 1/20 of the laser pulse width

Enhanced Performance in High-Speed and Ultrafast Systems

-

- Ideal where low jitter is essential for maintaining accurate pulse-to-pulse time intervals

- Ensures high precision for femtosecond laser machining, optical clocks, and LIDAR

- Maintain signal integrity in high-speed data transmission and telecom

Reliability & Versatility Across Industries

-

- Suitable for apps requiring high temporal accuracy

- Ensures reliable operation when timing precision & signal stability are critical

- Nanosecond to Picosecond options

For nearly 30 years, RPMC’s selection of Low Jitter Lasers has set the standard for affordable precision across a wide range of applications, from defense to medical, industrial, and research with 1000’s of successful units in the field. We understand that every application has unique requirements, which is why our configurable platforms are designed to offer the perfect fit for your needs—whether you’re working with fundamental wavelengths, harmonics, or specialty wavelengths. As your partner, we’re here to guide you through the selection process, ensuring that your low jitter laser integrates seamlessly into your existing systems. With time-tested technology that balances power and precision, we’re committed to supporting your success every step of the way.

SHIPS TODAY

SHIPS TODAY