The Nanosecond Lasers We Offer:

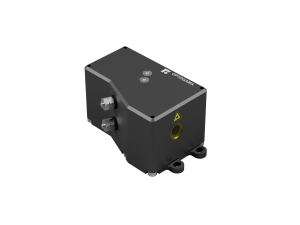

Highly flexible for various applications/materials

-

- Configurable platforms for tailored solutions

- Every market: Defense, Medical, Industrial, Research

- Easy integration into existing OEM systems

Attractively priced balance between power/precision

-

- Time-tested technology with competitive pricing

- High performance w/o the premium cost of shorter pulses

- Low total cost of ownership & low maintenance

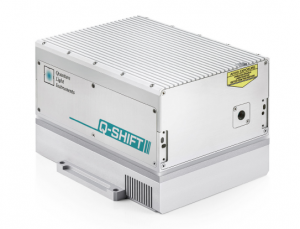

Wide range of wavelengths from IR to deep UV

-

- Fundamental wavelengths & up to 5th harmonics

- The right wavelength for your material or application

- From ceramics to delicate polymers to biological tissues

For nearly 30 years, RPMC’s selection of nanosecond lasers has set the standard for affordable precision across a wide range of applications, from defense to medical, industrial, and research with 1000’s of successful units in the field. We understand that every application has unique requirements, which is why our configurable platforms are designed to offer the perfect fit for your needs—whether you’re working with fundamental wavelengths, harmonics, or specialty wavelengths. As your partner, we’re here to guide you through the selection process, ensuring that your laser integrates seamlessly into your existing systems. With time-tested technology that balances power and precision, we’re committed to supporting your success every step of the way.

SHIPS TODAY

SHIPS TODAY