The Picosecond Lasers We Offer:

Customizable Platforms Tailored to Your Needs:

-

- Tailored solutions & flexible configuration with optional add-ons

- Easily integrated OEM or turnkey lab research versions

- DPSS, fiber & microchip options for various requirements

Balance Between Affordability & Advanced Performance:

-

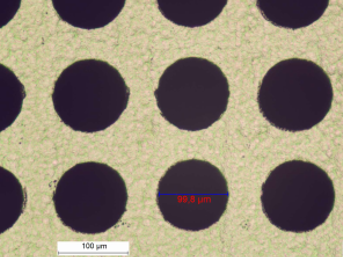

- Higher precision and reduced thermal effects vs nanosecond

- Excellent performance if you don’t require femtosecond quality

- 100s of ps to sub-10ps pulses – Single shot up to 80MHz PRR

Wide Range of Wavelengths from UV to SWIR & Tunable Options:

-

- UV, green & IR wavelength options w/ up to the 4th harmonic

- Tunable, narrow linewidth & broadband options

- Precision defense, medical, industrial & research applications

For nearly 30 years, RPMC has provided picosecond lasers that strike the perfect balance between affordability and high-precision performance. With customizable platforms and flexible configurations, our picosecond lasers deliver exceptional accuracy for applications requiring minimal thermal effects—ideal when nanosecond precision isn’t enough, but femtosecond isn’t required. From 100s of picoseconds down to sub-10ps, our lasers are optimized for OEM and turnkey systems, offering wavelengths from UV to SWIR with tunable options. Whether in defense, medical, industrial, or research environments, RPMC’s picosecond lasers provide reliable, high-quality performance for demanding tasks. As your trusted partner, we work with you to ensure seamless integration and long-term success, every step of the way.

SHIPS TODAY

SHIPS TODAY