The Ultrafast Lasers We Offer:

Wide Range of Wavelengths from UV to LWIR with Tunable Options

-

- UV, green & IR wavelengths w/ up to the 5th harmonic

- Tunable wavelengths 210-10000nm, narrow linewidth & broadband options

- Precision defense, medical, industrial & research applications

Ultrashort Pulses Ideal for Thermally Sensitive Materials

-

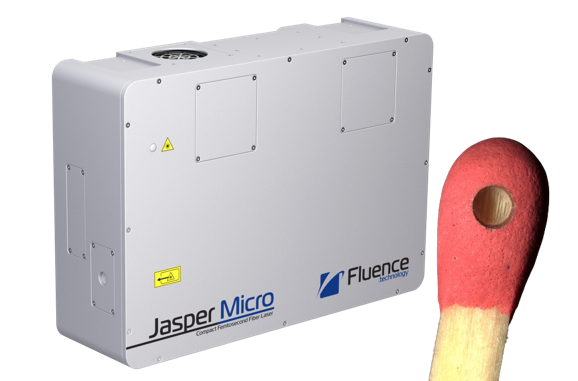

- Various picosecond & femtosecond pulse options w/ high pulse energies/peak power

- Minimized HAZ w/ cold ablation, excellent cut quality, advanced glass processing

- Tunable rep. rate & pulse width options extend application capabilities

For nearly 30 years, RPMC’s selection of Ultrafast Lasers has set the standard for affordable precision across a wide range of applications, from defense to medical, industrial, and research with 1000’s of successful units in the field. We understand that every application has unique requirements, which is why our configurable platforms are designed to offer the perfect fit for your needs—whether you’re working with fundamental wavelengths, harmonics, or specialty wavelengths. As your partner, we’re here to guide you through the selection process, ensuring that your ultrafast laser integrates seamlessly into your existing systems. With time-tested technology that balances power and precision, we’re committed to supporting your success every step of the way.

SHIPS TODAY

SHIPS TODAY