The Blue Lasers We Offer:

Wide Range of Blue Laser Types & Configurations

-

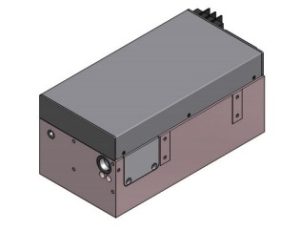

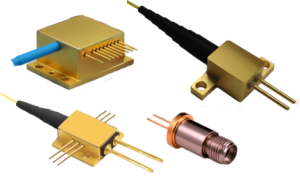

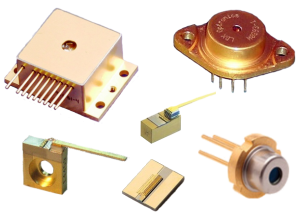

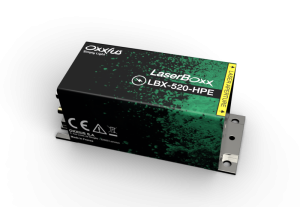

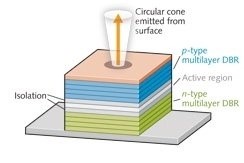

- Blue laser diodes and DPSS systems in compact modules to high-power configurations

- Available in single-mode or multimode, free-space or fiber-coupled output

- Customizable from components to turnkey systems for tailored integration

High Power, Absorption & Precision for Industrial and Scientific Applications

-

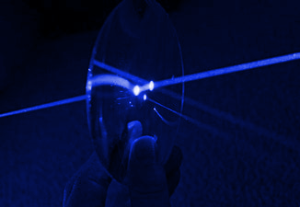

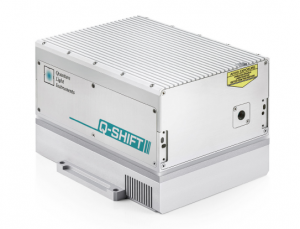

- Shorter wavelengths enable smaller spot sizes, enhancing resolution for various applications

- High absorption in metals like copper – spatter-free welding & efficient material processing

- Power levels up to 2kW for high-demand welding applications, focused beam options

Optimized for Holography, Interferometry & Bio-Imaging

-

- Ideal for high-resolution imaging, flow cytometry, and surface roughness measurements

- Enhanced absorption enables efficient metal marking, cutting & processing applications

- Supports holography, LIBS, and laser displays for varied scientific and industrial uses

For nearly 30 years, RPMC’s selection of Bluet Lasers has set the standard for affordable precision across a wide range of applications, from defense to medical, industrial, and research with 1000’s of successful units in the field. We understand that every application has unique requirements, which is why our configurable platforms are designed to offer the perfect fit for your needs—whether you’re working with fundamental wavelengths, harmonics, or specialty wavelengths. As your partner, we’re here to guide you through the selection process, ensuring that your blue laser integrates seamlessly into your existing systems. With time-tested technology that balances power and precision, we’re committed to supporting your success every step of the way.

SHIPS TODAY

SHIPS TODAY