Overview:

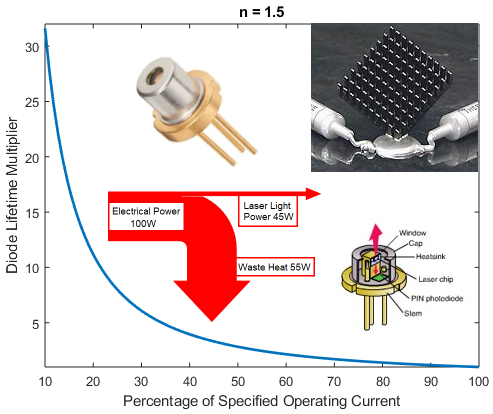

Over the years, laser diode development has led to increased output power, which is excellent for many applications, except you are now contending with added waste heat. The mounting or heatsinking of the laser package is of tremendous importance because operating temperature strongly influences laser lifetime and performance. Effectively achieving correct mounting or heatsinking of the laser package is not as simple as many would assume. This article will discuss the various package types and the best practices for ensuring the laser diode is mounted correctly. Ensuring the laser diode is mounted correctly will provide the best performance and most extended lifetimes.

Laser Diodes (Semiconductor Lasers):

Laser diode is a generic term that includes several different semiconductor lasers and many additional types of housings or packages for these semiconductor lasers. The more common types of semiconductor lasers include:

1. Fabry-Perot Laser Diodes – This is the simplest form of laser diode, typically called edge emitters. These lasers can be single-mode, multimode, or used as an array of emitters (bar) to achieve much higher powers. Available in the UV, visible, and infrared wavelengths.

2. Stabilized Laser Diodes – This type of laser diode utilizes an optical element to introduce feedback into the laser cavity. This feedback mechanism can be internal or external to the actual laser cavity. Some examples include Distributed Bragg Reflector (DBR) lasers, Distributed feedback (DFB) lasers, and external-cavity (EC) lasers. Available primarily in the visible and infrared wavelengths.

3. Vertical-Cavity Surface-Emitting Lasers (VCSEL) – VCSELs have an optical cavity perpendicular to the mounting surface. VCSELs have advantages such as circular beam profile and reduced speckle. Available in visible and infrared wavelengths.

4. Quantum Cascade (QCLs) and Interband Cascade Lasers – QCLs are intersubband semiconductor lasers emitting in the mid-infrared (MWIR) to far-infrared or long-wave infrared (LWIR) portion of the electromagnetic spectrum from 4 to 16 µm. Fabry-Perot QCLs provide quasi-continuous wave (QCW) multimode output. Distributed feedback (DFB) QCLs provide continuous wave (CW), single-mode output with narrow line widths. Available in the mid-infrared wavelengths.

These semiconductor lasers are called laser diodes, and most, if not all, of the advice and mounting procedures discussed below, apply to all laser diodes.

Laser Diode Housings and Packages:

Most of the laser diode types discussed above are available in many different housings or package types, depending on the output power of the laser and the options needed. We will group these package types into the following groups: Open Packages, Sealed Packages, and Fiber-Coupled Packages. Each group has some specific requirements and concerns to achieve the best performance. Before we get to the specifics for each package group, here are some general advice and precautions applicable to all laser diodes.

General Advice and Precautions for all laser diodes:

1. Laser Classification – You should know the classification of your laser and take the necessary precautions to avoid direct or indirect laser light. Medium and high-power lasers are potentially hazardous because they can burn skin or even the eye's retina. To control the risk of injury, various specifications, for example, 21 Code of Federal Regulations (CFR) Part 1040 in the US and IEC 60825 internationally, define "classes" of laser depending on their power and wavelength. Alternatively, you can purchase a fantastic Laser Safety Guide from the Laser Institute of America to keep on hand: https://www.lia.org/store/product/laser-safety-guide. This guide covers safety standards, hazard classification, eye protection, etc.

2. Eye Safety – Working with lasers can be dangerous, especially to the naked eye. Laser goggles, protective enclosures, etc., should be used in addition to safety equipment such as "Laser Active" signs, door interlocks, and switches. Ideally, diode lasers should operate in a sealed, light-tight box equipped with interlock switches that cause the laser to shut down when the enclosure is open instantly.

3. Electrostatic Discharge (ESD) – Most laser diodes are very sensitive to damage by electrostatic discharge (ESD) or other voltage transients. ESD procedures are required when handling laser diodes. During shipment, the laser diode will be in a conductive plastic bag, and when possible, the anode and cathode electrical contacts are shorted together to prevent ESD damage. When the laser is not connected to a power supply, the user should also short the anode and cathode electrical contacts. All persons and tools that may contact the laser must be continuously grounded, for example, with a grounding strap. A grounding strap is a device worn by the user that creates an electrical connection to ground. This measure protects electronic equipment from electrostatic discharges that could damage or destroy the laser diode.

4. Unpacking – Before opening the conductive plastic bag, choose a clean environment where you will unpack the diode lasers and keep them there for at least 4 hours to achieve thermal equilibrium. The handling personnel and the tools used for handling must be grounded for ESD-protection purposes. During handling, the personnel should wear clean gloves and use plastic tweezers to avoid contaminating the facets of the laser. Some lasers may be secured to a transport plate by fixing screws. Understand which screws are fixing screws and which screws are part of the assembly. Do not loosen the assembly screws which keep the diode laser together. The fixing screws may also be the short-circuit between the anode and cathode electrical contacts to prevent ESD damage. The laser diodes must be kept in a clean and dry atmosphere with a temperature range of 0°C to 60°C once removed from the shipping containers.

5. Cleaning – Solvents, plastics, glues, and heat conductive paste are not allowed near the laser diodes. These substances can outgas and deposit on optical surfaces, including the laser diode facets. The laser diode front facet is extremely sensitive and must be kept free of contamination (e.g., dust, water, gas, etc.). Any contamination on the laser's front facet will lead to irreversible damage and failure of the laser diode, even if there is no sudden failure. There is no way to clean the front facet of a laser diode. The semiconductor crystal and its coatings are very sensitive to any kind of solvents and liquids, and mechanical methods could damage coatings or the facet itself. Do not touch the laser front facet with any object!

6. Laser Diode Driver – The operation of laser diodes relies on using an approved laser diode driver that is current-regulated and designed explicitly for laser diodes. Off-the-shelf power supplies can deliver a high current spike upon energizing or produce a very short duration reverse biasing when turning off the unit. Either of these instances will damage or destroy the diode laser. Laser diodes are very sensitive to current and voltage spikes. Current and voltage spiking must be avoided when switching the power supply on and off and when operating the diode laser. The residual ripple of the current must not exceed a value of +/- 10 %. The diode driver should also include a safety circuit that switches the system off within approximately 100 ms in the case of faults. Faults are all conditions that put the safety of persons or the device at risk. Read a more in-depth article on laser diode drivers: “Why Shouldn’t You Voltage Drive a Laser Diode?”

7. Electrical Connections – Most laser diode drivers have a provision to disable the supply and short the output to allow for connection of the diode. Never make the connection to the laser diode with the power supply voltage on.

8. Thermally-conductive Compounds – Pastes are typically not recommended for lasers. The liquids contained in these pastes liberate gas over time and can deposit on optical surfaces. Also, ov

SHIPS TODAY

SHIPS TODAY