Display and Electronics Manufacturing Lasers

What are Display and Electronics Manufacturing Lasers?

What are Display and Electronics Manufacturing Lasers?

Display and electronics manufacturing lasers are specialized tools used in the fabrication, assembly, and testing of electronic components and display technologies. These pulsed lasers offer precise and controlled energy deposition during various manufacturing stages, ensuring high-quality production. They find applications in semiconductor manufacturing, PCB fabrication, display production (such as OLED and LCD), and other electronic manufacturing processes. Display and electronics manufacturing lasers enable precise patterning, drilling, cutting, repair, and other essential tasks, contributing to efficient and accurate manufacturing processes.

Have questions?

Display and Electronics Manufacturing Applications

LCD Repair Lasers: LCD repair lasers selectively cut out a bad pixel that is affecting the display, restoring overall display quality without having to scrap and replace the screen. These lasers are focused down through a high magnification microscope to ablate the defect. These LCD repair lasers must have high-quality beam profiles to be focused down to the size of the pixel, as well as high pulse energy (typically ns pulsed).

OLED Production Lasers: OLED production lasers are specialized for manufacturing OLED displays, patterning organic materials with precision, aiding in encapsulation, facilitating the repair processes, and improving display quality by correcting defects and non-functional pixels. 3rd & 4th harmonic DPSS lasers (typically ns or ps pulsed UV) are ideal for OLED production because they provide high-quality repeatable pulses ideal for high volume mass production.

PCB Production Lasers: PCB manufacturing requires high throughput, accuracy, and precision, involving laser soldering, laser etching, laser trimming, and laser cutting/drilling in the automated manufacturing process. Since the uses for PCB production lasers vary so widely, so do their properties, but in general, these lasers (typically ns or ps pulsed, single-mode) tend to be single spatial mode to allow for the laser to be focused down to a tiny spot. Additionally, these lasers are often beam shaped depending on the exact need of the weld or cut.

Resistor Trimming Lasers: Laser trimming (typically ns or ps pulsed, high quality TEM00 beam) is commonly used in the electronics industry for removing small amounts of material in integrated circuits to optimize their performance, adjusting resistor values, and can be used on capacitors and other thin film components in the circuit. One significant advantage of laser trimming is that it allows for active adjustments to be made while critical parameters of the devices are actively monitored.

Scribing Lasers: Laser scribing is a process that involves using a laser beam (typically ns or ps pulsed q-switched) to create precise, controlled cuts or lines on a surface. It is commonly used in industries such as electronics, solar cell manufacturing, and thin-film deposition. By adjusting the laser’s power, speed, and focus, laser scribing can produce fine grooves, channels, or patterns on materials like glass, silicon, metals, or ceramics.

Lithography Lasers: (Pulsed & CW, SLM, single-mode, UV & blue) Photolithography is a material processing technique which is widely used in the semiconductor industry for etching nanoscale structures into wafers. This process transfers shapes from a photomask to the wafer using ultraviolet light either by a gas discharge lamp or by ultraviolet lithography lasers. UV light is traditionally used in photolithography because the minimum image size of an optical system is dependent on the wavelength of light.

Recommended Laser Series

We recommend the following laser series options for Display & Electronics Manufacturing applications. There can often be a ton of options and many variables. Contact us today for help finding the perfect laser for your specific application!

Have questions?

SHIPS TODAY

SHIPS TODAY  What are Display and Electronics Manufacturing Lasers?

What are Display and Electronics Manufacturing Lasers? The FL CW/CW Modulated Series of CW fiber lasers is manufactured to Telcordia standards and is suitable for various applications with powers up to 100W at 1um, 30W at 1.5um, and 40W at 2um. Available in both OEM and Turnkey formats, this series offers a variety of standard and custom configurations. Available options and configurations include narrow linewidth, single frequency outputs, C and L-band broadband sources, PM fiber options, power tunability, and high-speed trig./mod.

The FL CW/CW Modulated Series of CW fiber lasers is manufactured to Telcordia standards and is suitable for various applications with powers up to 100W at 1um, 30W at 1.5um, and 40W at 2um. Available in both OEM and Turnkey formats, this series offers a variety of standard and custom configurations. Available options and configurations include narrow linewidth, single frequency outputs, C and L-band broadband sources, PM fiber options, power tunability, and high-speed trig./mod. The Aero Series is a high-energy, nanosecond pulsed DPSS laser, available at 266, 355, 532, and 1064nm, with up to 10W output power at 1064 (up to 200 mJ with water-cooling). This series provides unparalleled precision and accuracy in even the most challenging environments, ideal for LIBS, spectroscopy, and atmospheric LIDAR applications. All models come enclosed in an air-cooled, extremely compact and ruggedized, thermo-mechanically stable, low SWaP single unit platform, with options for air- or water-cooling, a range of add-ons, and even complete customization to fit your exact needs. Upon request, customized models undergo severe vibration and qualification tests for operation in space.

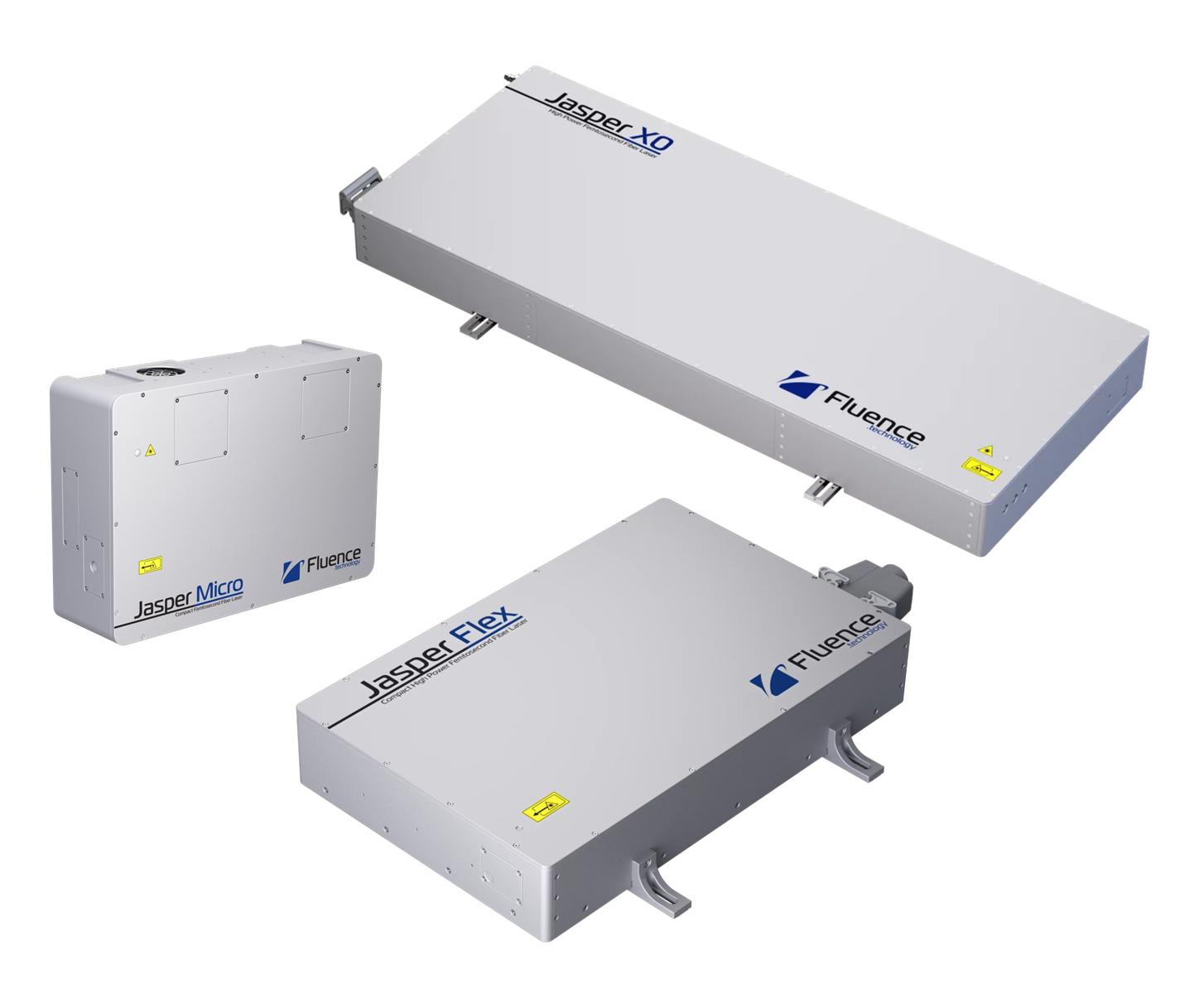

The Aero Series is a high-energy, nanosecond pulsed DPSS laser, available at 266, 355, 532, and 1064nm, with up to 10W output power at 1064 (up to 200 mJ with water-cooling). This series provides unparalleled precision and accuracy in even the most challenging environments, ideal for LIBS, spectroscopy, and atmospheric LIDAR applications. All models come enclosed in an air-cooled, extremely compact and ruggedized, thermo-mechanically stable, low SWaP single unit platform, with options for air- or water-cooling, a range of add-ons, and even complete customization to fit your exact needs. Upon request, customized models undergo severe vibration and qualification tests for operation in space. The Jasper series is a diverse set of high-performance femtosecond fiber lasers providing different solutions based on a standard technology. The series includes the high-power Jasper X0 (200 µJ pulse energy / 60 W average power), the compact Jasper Micro (5 µJ pulse energy / 7 W average power) in a space-saving design, and the Jasper Flex for microprocessing (30 µJ pulse energy). Each model provides a fast warm-up time, long-term stability, and hands-free operation. Whether you need high power, compactness, or specific processing capabilities, the Jasper series has a solution.

The Jasper series is a diverse set of high-performance femtosecond fiber lasers providing different solutions based on a standard technology. The series includes the high-power Jasper X0 (200 µJ pulse energy / 60 W average power), the compact Jasper Micro (5 µJ pulse energy / 7 W average power) in a space-saving design, and the Jasper Flex for microprocessing (30 µJ pulse energy). Each model provides a fast warm-up time, long-term stability, and hands-free operation. Whether you need high power, compactness, or specific processing capabilities, the Jasper series has a solution.

The Lampo Series is a line of compact ultrafast lasers that deliver megawatt-level ps laser pulses at a selectable PRR from 50 kHz to 40 MHz. Available in IR (1064 nm), SHG (532 nm), and Deep-UV (266 nm) versions (355nm by request), the series offers pulse durations < 70 ps and average power up to 20W, 10W, and 1.5W respectively. With pulse energy up to 250uJ, 150uJ, and 30uJ, these lasers are ideal for a wide range of scientific, industrial, defense, medical, biological, and LIDAR applications. Built into a rugged, air-cooled single-unit laser head, these lasers are easy to operate and integrate, making them a valuable tool for sophisticated laser systems and lab applications.

The Lampo Series is a line of compact ultrafast lasers that deliver megawatt-level ps laser pulses at a selectable PRR from 50 kHz to 40 MHz. Available in IR (1064 nm), SHG (532 nm), and Deep-UV (266 nm) versions (355nm by request), the series offers pulse durations < 70 ps and average power up to 20W, 10W, and 1.5W respectively. With pulse energy up to 250uJ, 150uJ, and 30uJ, these lasers are ideal for a wide range of scientific, industrial, defense, medical, biological, and LIDAR applications. Built into a rugged, air-cooled single-unit laser head, these lasers are easy to operate and integrate, making them a valuable tool for sophisticated laser systems and lab applications. The MicroMake Series is a fully-integrated, compact, sub-ns DPSS laser micromachining system for high precision and resolution applications. A flexible platform at 532 & 266 nm, with >40 kW of peak power and processing speeds up to 100mm/second, the system includes all the needed devices for direct laser micro-processing in a single, monolithic, air-cooled configuration. Equipped with a live microscope, alignments and in-process quality checks are a breeze. All these features perfectly suit various materials utilized in microelectronic circuits, displays fabrication and correction, biomedical device machining and optical substrates microprocessing.

The MicroMake Series is a fully-integrated, compact, sub-ns DPSS laser micromachining system for high precision and resolution applications. A flexible platform at 532 & 266 nm, with >40 kW of peak power and processing speeds up to 100mm/second, the system includes all the needed devices for direct laser micro-processing in a single, monolithic, air-cooled configuration. Equipped with a live microscope, alignments and in-process quality checks are a breeze. All these features perfectly suit various materials utilized in microelectronic circuits, displays fabrication and correction, biomedical device machining and optical substrates microprocessing. The neoMOS ultrashort pulse laser series is a reliable, low-maintenance system designed for 24/7 industrial use. The ultra-compact laser head has the smallest footprint available and can be customized for a range of laser parameters, allowing easy integration and flexibility with various demanding processing applications, including glasses and plastics. It offers pulse widths from 700fs to 70ps, repetition rates from single-shot to 80MHz, up to 500µJ pulse energy, average output powers up to 100W, multi-megawatt peak powers, and perfect TEM00 beam quality @ 1064nm.

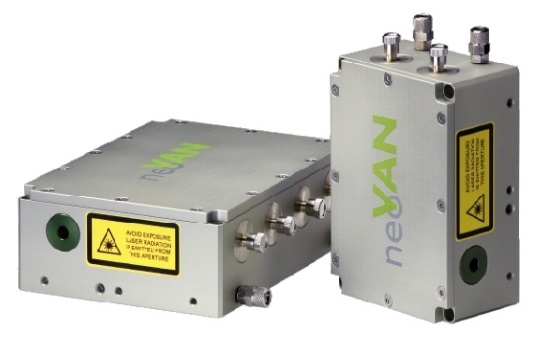

The neoMOS ultrashort pulse laser series is a reliable, low-maintenance system designed for 24/7 industrial use. The ultra-compact laser head has the smallest footprint available and can be customized for a range of laser parameters, allowing easy integration and flexibility with various demanding processing applications, including glasses and plastics. It offers pulse widths from 700fs to 70ps, repetition rates from single-shot to 80MHz, up to 500µJ pulse energy, average output powers up to 100W, multi-megawatt peak powers, and perfect TEM00 beam quality @ 1064nm. The neoAMP series includes the neoVAN and neoYb DPSS laser amplifiers, designed to boost the average power or pulse energy for various applications. The flexible system design ensures high scalability, and the ultra-compact modules are easy to integrate into existing processing or scientific systems. The neoVAN and neoYb amplifiers are highly reliable and offer proven long-term stability, enabling a range of applications that include high peak power, short pulse picosecond lasers for micromachining, or single-frequency radiation for gravitational wave detection.

The neoAMP series includes the neoVAN and neoYb DPSS laser amplifiers, designed to boost the average power or pulse energy for various applications. The flexible system design ensures high scalability, and the ultra-compact modules are easy to integrate into existing processing or scientific systems. The neoVAN and neoYb amplifiers are highly reliable and offer proven long-term stability, enabling a range of applications that include high peak power, short pulse picosecond lasers for micromachining, or single-frequency radiation for gravitational wave detection.