Material Processing & Surface Modification Lasers

What are Material Processing & Surface Modification Lasers?

What are Material Processing & Surface Modification Lasers?

Material Processing lasers are advanced tools that utilize the power of focused laser light (typically pulsed) to modify and transform various types of materials. Material processing lasers can perform tasks such as cutting, engraving, drilling, marking, micromachining, and non-thermal ablation with precision and efficiency. The versatility and high degree of control offered by these lasers make them indispensable tools for achieving intricate and complex material alterations, contributing to advancements in technology and enhancing industrial processes.

Surface Modification lasers are specialized tools used to alter the properties and characteristics of various materials at the surface level, typically utilizing pulsed lasers. These lasers utilize precise energy deposition to induce physical or chemical changes in the targeted material, resulting in desired modifications. There are several techniques employed in surface modification and treatment, each with its own laser system and methodology. Some common examples include texturing, peening, and marking applications.

Have questions?

Material Processing & Surface Modification Laser Applications

Cutting/Drilling Lasers: Laser cutting and drilling is a process in which q-switched lasers (typically high power, ns pulsed) are used to thermally ablate material to form holes and cuts in various materials, including metals, polymers, ceramics, and more. In both laser cutting and drilling the primary objective is to remove material, and as such, the vaporized material must be allowed to outgas, so that is don’t interfere with the process allowing for precise cuts.

Micromachining Lasers: Laser micromachining is a collection of processes involving sub-millimeter machining of small parts or features on a material using precise and controlled techniques. This subtractive (material removal) process typically involves using specialized micromachining lasers (typically ps or fs pulsed, UV green & IR) to cut, drill, ablate, or otherwise shape materials with accuracy and precision.

Non-Thermal Ablation Lasers: Non-thermal ablation, often performed using ultrafast lasers, is an advanced method employed to remove material with exceptional precision and minimal heat-induced damage. This technique relies on ultra-short laser pulses (typically ps or fs pulsed) which deliver an intense burst of energy in a fraction of a second, removing material through non-thermal or cold ablation.

Thin Film Removal Lasers: Laser thin film removal is the process of selectively ablating a very thin layer of material from a substrate, and is widely used on silicon, glass, ceramics, plastics, and metals. These lasers are generally short-pulsed (typically fs, ps or even ns pulsed UV green & IR, high quality TEM00 beam) with the ability to operate at high repetition rates to allow for sufficient pulse overlap at high processing speeds without damaging the substrate.

Marking Lasers: Laser marking is a process of creating permanent marks or patterns on a material’s surface using laser technology. Unlike traditional marking methods like ink printing or engraving, laser marking offers advantages such as high precision, durability, non-contact processing, and the ability to mark a wide range of materials. Laser marking lasers are specifically designed lasers used for the marking process (typically ns or ps pulsed q-switched).

Texturing Lasers: Laser texturing involves engraving the negative image of an intricate design into a mold to produce an end product with a raised decorative patterned surface, allowing molded parts to mimic the look of leather, wood, and other materials. Laser engraving (typically ns or ps pulsed with high quality TEM00 beam) the interior of the mold instead of chemically etching it eliminates the need for hazardous, corrosive chemicals and allows for a completely digitized process.

Recommended Laser Series

We recommend the following laser series for Material Processing & Surface Modification applications. There can often be a ton of options and many variables. Contact us today for help finding the perfect laser for your specific application!

Have questions?

SHIPS TODAY

SHIPS TODAY  What are Material Processing & Surface Modification Lasers?

What are Material Processing & Surface Modification Lasers? The Aero Series is a high-energy, nanosecond pulsed DPSS laser, available at 266, 355, 532, and 1064nm, with up to 10W output power at 1064 (up to 200 mJ with water-cooling). This series provides unparalleled precision and accuracy in even the most challenging environments, ideal for LIBS, spectroscopy, and atmospheric LIDAR applications. All models come enclosed in an air-cooled, extremely compact and ruggedized, thermo-mechanically stable, low SWaP single unit platform, with options for air- or water-cooling, a range of add-ons, and even complete customization to fit your exact needs. Upon request, customized models undergo severe vibration and qualification tests for operation in space.

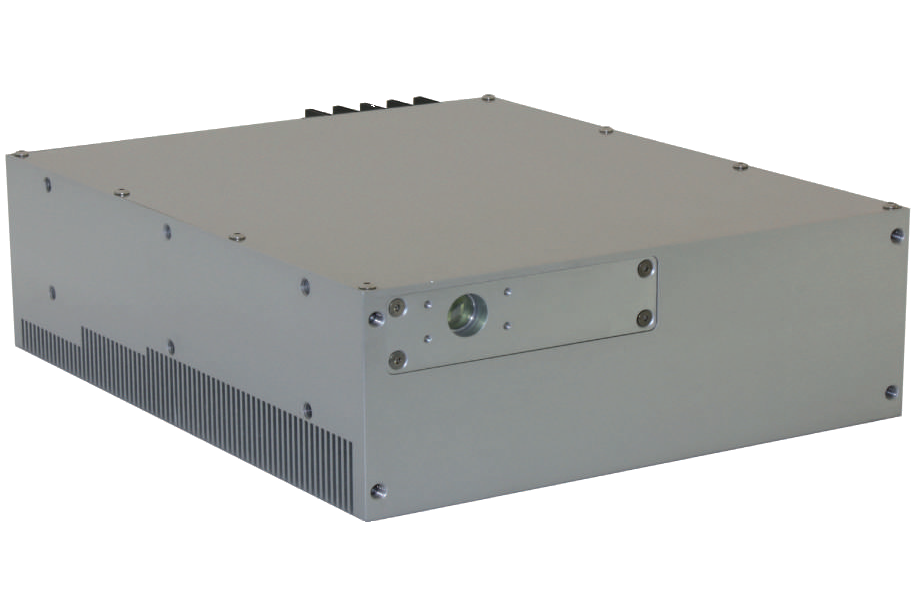

The Aero Series is a high-energy, nanosecond pulsed DPSS laser, available at 266, 355, 532, and 1064nm, with up to 10W output power at 1064 (up to 200 mJ with water-cooling). This series provides unparalleled precision and accuracy in even the most challenging environments, ideal for LIBS, spectroscopy, and atmospheric LIDAR applications. All models come enclosed in an air-cooled, extremely compact and ruggedized, thermo-mechanically stable, low SWaP single unit platform, with options for air- or water-cooling, a range of add-ons, and even complete customization to fit your exact needs. Upon request, customized models undergo severe vibration and qualification tests for operation in space. The Halite 2 series is a compact, single-box, all-fiber femtosecond laser designed to meet the most demanding applications in neuroscience, biophotonics, microscopy, and engineering. With pulses as short as <250 fs (< 100 fs op.), average power over 2 W at 1030 nm, and the option of second harmonic at 515 nm, it is an irreplaceable tool in every lab that needs a reliable, turn-key, ultrafast light source. Thanks to its unique construction and SESAM-free technology, it is a cost-effective solution that provides high pulse energy (over 100 nJ), excellent beam quality, and easy integration.

The Halite 2 series is a compact, single-box, all-fiber femtosecond laser designed to meet the most demanding applications in neuroscience, biophotonics, microscopy, and engineering. With pulses as short as <250 fs (< 100 fs op.), average power over 2 W at 1030 nm, and the option of second harmonic at 515 nm, it is an irreplaceable tool in every lab that needs a reliable, turn-key, ultrafast light source. Thanks to its unique construction and SESAM-free technology, it is a cost-effective solution that provides high pulse energy (over 100 nJ), excellent beam quality, and easy integration.

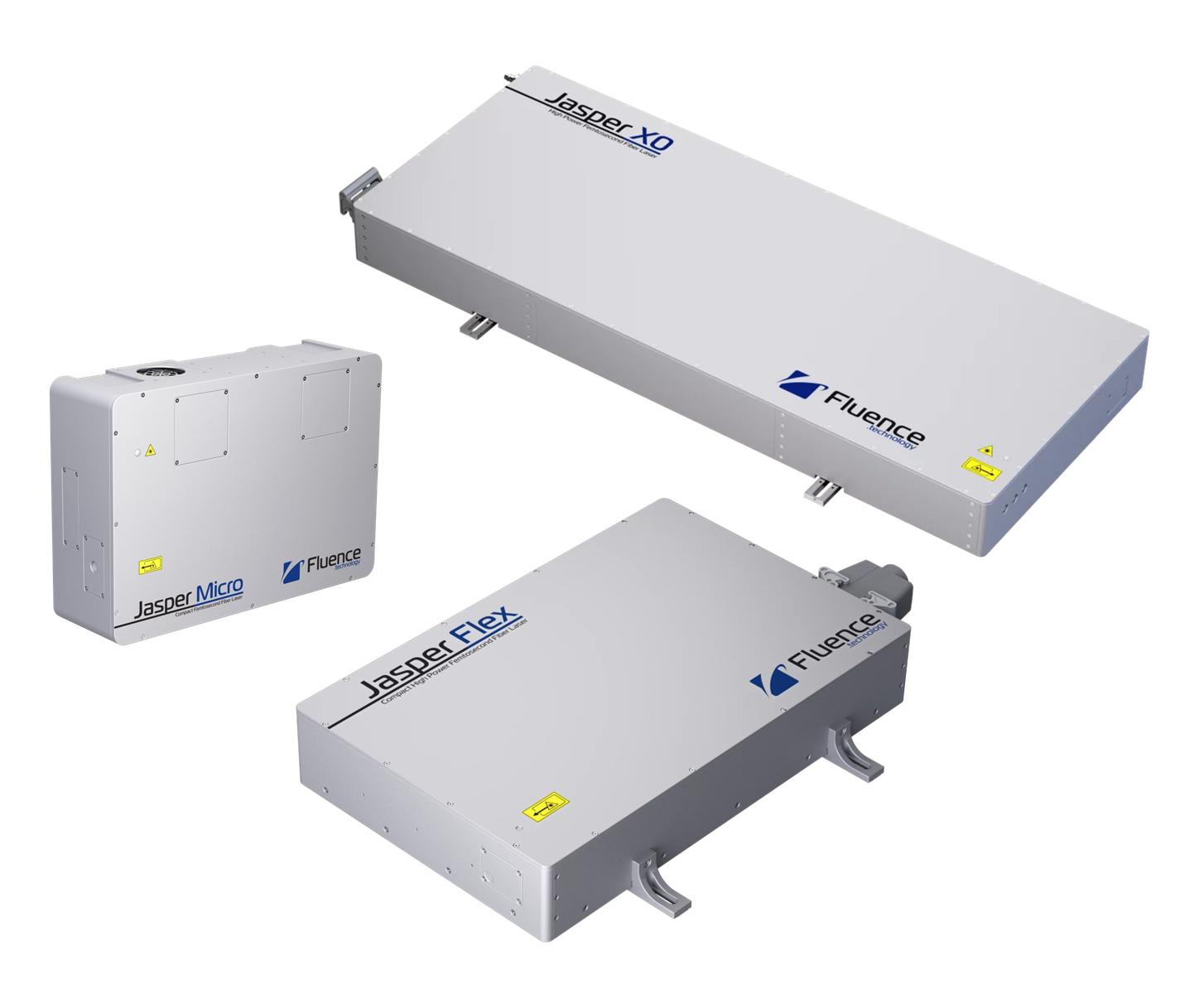

The Jasper series is a diverse set of high-performance femtosecond fiber lasers providing different solutions based on a standard technology. The series includes the high-power Jasper X0 (200 µJ pulse energy / 60 W average power), the compact Jasper Micro (5 µJ pulse energy / 7 W average power) in a space-saving design, and the Jasper Flex for microprocessing (30 µJ pulse energy). Each model provides a fast warm-up time, long-term stability, and hands-free operation. Whether you need high power, compactness, or specific processing capabilities, the Jasper series has a solution.

The Jasper series is a diverse set of high-performance femtosecond fiber lasers providing different solutions based on a standard technology. The series includes the high-power Jasper X0 (200 µJ pulse energy / 60 W average power), the compact Jasper Micro (5 µJ pulse energy / 7 W average power) in a space-saving design, and the Jasper Flex for microprocessing (30 µJ pulse energy). Each model provides a fast warm-up time, long-term stability, and hands-free operation. Whether you need high power, compactness, or specific processing capabilities, the Jasper series has a solution.

The Lampo Series is a line of compact ultrafast lasers that deliver megawatt-level ps laser pulses at a selectable PRR from 50 kHz to 40 MHz. Available in IR (1064 nm), SHG (532 nm), and Deep-UV (266 nm) versions (355nm by request), the series offers pulse durations < 70 ps and average power up to 20W, 10W, and 1.5W respectively. With pulse energy up to 250uJ, 150uJ, and 30uJ, these lasers are ideal for a wide range of scientific, industrial, defense, medical, biological, and LIDAR applications. Built into a rugged, air-cooled single-unit laser head, these lasers are easy to operate and integrate, making them a valuable tool for sophisticated laser systems and lab applications.

The Lampo Series is a line of compact ultrafast lasers that deliver megawatt-level ps laser pulses at a selectable PRR from 50 kHz to 40 MHz. Available in IR (1064 nm), SHG (532 nm), and Deep-UV (266 nm) versions (355nm by request), the series offers pulse durations < 70 ps and average power up to 20W, 10W, and 1.5W respectively. With pulse energy up to 250uJ, 150uJ, and 30uJ, these lasers are ideal for a wide range of scientific, industrial, defense, medical, biological, and LIDAR applications. Built into a rugged, air-cooled single-unit laser head, these lasers are easy to operate and integrate, making them a valuable tool for sophisticated laser systems and lab applications. The MicroMake Series is a fully-integrated, compact, sub-ns DPSS laser micromachining system for high precision and resolution applications. A flexible platform at 532 & 266 nm, with >40 kW of peak power and processing speeds up to 100mm/second, the system includes all the needed devices for direct laser micro-processing in a single, monolithic, air-cooled configuration. Equipped with a live microscope, alignments and in-process quality checks are a breeze. All these features perfectly suit various materials utilized in microelectronic circuits, displays fabrication and correction, biomedical device machining and optical substrates microprocessing.

The MicroMake Series is a fully-integrated, compact, sub-ns DPSS laser micromachining system for high precision and resolution applications. A flexible platform at 532 & 266 nm, with >40 kW of peak power and processing speeds up to 100mm/second, the system includes all the needed devices for direct laser micro-processing in a single, monolithic, air-cooled configuration. Equipped with a live microscope, alignments and in-process quality checks are a breeze. All these features perfectly suit various materials utilized in microelectronic circuits, displays fabrication and correction, biomedical device machining and optical substrates microprocessing. The neoMOS ultrashort pulse laser series is a reliable, low-maintenance system designed for 24/7 industrial use. The ultra-compact laser head has the smallest footprint available and can be customized for a range of laser parameters, allowing easy integration and flexibility with various demanding processing applications, including glasses and plastics. It offers pulse widths from 700fs to 70ps, repetition rates from single-shot to 80MHz, up to 500µJ pulse energy, average output powers up to 100W, multi-megawatt peak powers, and perfect TEM00 beam quality @ 1064nm.

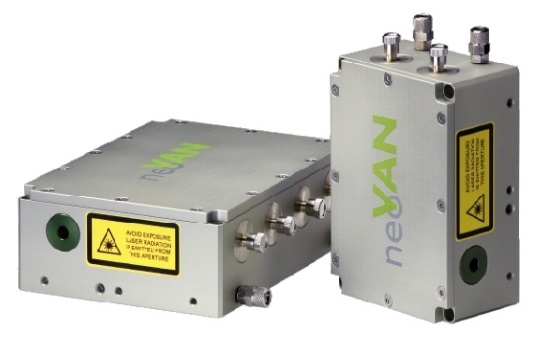

The neoMOS ultrashort pulse laser series is a reliable, low-maintenance system designed for 24/7 industrial use. The ultra-compact laser head has the smallest footprint available and can be customized for a range of laser parameters, allowing easy integration and flexibility with various demanding processing applications, including glasses and plastics. It offers pulse widths from 700fs to 70ps, repetition rates from single-shot to 80MHz, up to 500µJ pulse energy, average output powers up to 100W, multi-megawatt peak powers, and perfect TEM00 beam quality @ 1064nm. The neoAMP series includes the neoVAN and neoYb DPSS laser amplifiers, designed to boost the average power or pulse energy for various applications. The flexible system design ensures high scalability, and the ultra-compact modules are easy to integrate into existing processing or scientific systems. The neoVAN and neoYb amplifiers are highly reliable and offer proven long-term stability, enabling a range of applications that include high peak power, short pulse picosecond lasers for micromachining, or single-frequency radiation for gravitational wave detection.

The neoAMP series includes the neoVAN and neoYb DPSS laser amplifiers, designed to boost the average power or pulse energy for various applications. The flexible system design ensures high scalability, and the ultra-compact modules are easy to integrate into existing processing or scientific systems. The neoVAN and neoYb amplifiers are highly reliable and offer proven long-term stability, enabling a range of applications that include high peak power, short pulse picosecond lasers for micromachining, or single-frequency radiation for gravitational wave detection.

The Q-DOUBLE series is a DPSS, air-cooled, q-switched laser at 1064 or 1053 nm, designed to produce two pulses with variable temporal separation for PIV, LIBS, and other applications. The Q-DOUBLE can be configured for up to 160 mJ pulse energy @ 10 Hz or up to 40 mJ @ 100 Hz. The innovative laser design integrates all electronics (except power adapter) into the housing, resulting in a compact, user-friendly, turnkey, and air-cooled (water-free) system requiring little maintenance. User-friendly web-based GUI allows remote monitoring, control, and support from any computer or even a smartphone. Optional add-ons include built-in 2nd, 3rd, or 4th harmonic generator, built-in attenuator, energy monitor, and optional short cavity version.

The Q-DOUBLE series is a DPSS, air-cooled, q-switched laser at 1064 or 1053 nm, designed to produce two pulses with variable temporal separation for PIV, LIBS, and other applications. The Q-DOUBLE can be configured for up to 160 mJ pulse energy @ 10 Hz or up to 40 mJ @ 100 Hz. The innovative laser design integrates all electronics (except power adapter) into the housing, resulting in a compact, user-friendly, turnkey, and air-cooled (water-free) system requiring little maintenance. User-friendly web-based GUI allows remote monitoring, control, and support from any computer or even a smartphone. Optional add-ons include built-in 2nd, 3rd, or 4th harmonic generator, built-in attenuator, energy monitor, and optional short cavity version.

The Q-TUNE-HR series is a high repetition rate OPO producing a tunable wavelength range from ≈ 750 – 1800 nm and up to 100 kHz pulse repetition rate, the perfect coherent light source for micromachining, Raman spectroscopy, microscopy, and remote sensing applications. Q-TUNE-HR requires an external pump source with > 350 μJ pulse energy and 5 – 7 ns FWHM pulse duration @ 532 nm for operation: pulse repetition rate can be in 10 – 100 kHz range and acceptable pump power in the 3.5 – 30 W range. By default OPO is optimized to produce maximum output in 1200 – 1800 nm range (optional: 750 – 950 nm). In addition to the tunable range, the pump laser wavelength is accessible through a convenient bypass port.

The Q-TUNE-HR series is a high repetition rate OPO producing a tunable wavelength range from ≈ 750 – 1800 nm and up to 100 kHz pulse repetition rate, the perfect coherent light source for micromachining, Raman spectroscopy, microscopy, and remote sensing applications. Q-TUNE-HR requires an external pump source with > 350 μJ pulse energy and 5 – 7 ns FWHM pulse duration @ 532 nm for operation: pulse repetition rate can be in 10 – 100 kHz range and acceptable pump power in the 3.5 – 30 W range. By default OPO is optimized to produce maximum output in 1200 – 1800 nm range (optional: 750 – 950 nm). In addition to the tunable range, the pump laser wavelength is accessible through a convenient bypass port.

The VaryDisk Series is a versatile family of thin-disk laser systems that provide high pulse energies at high average powers and are suitable for lab or industrial use. These thin-disk regenerative amplifiers offer a range of output specifications to fit various application needs. The base configurations provide 25 W average power with 2.5 mJ pulse energy @ 343 nm (THG), 50 W and 5 mJ @ 515 nm (SHG), and 100W and 100 mJ @ 1030 nm.

The VaryDisk Series is a versatile family of thin-disk laser systems that provide high pulse energies at high average powers and are suitable for lab or industrial use. These thin-disk regenerative amplifiers offer a range of output specifications to fit various application needs. The base configurations provide 25 W average power with 2.5 mJ pulse energy @ 343 nm (THG), 50 W and 5 mJ @ 515 nm (SHG), and 100W and 100 mJ @ 1030 nm.